tableau.com is not available in your region.

Have a language expert improve your writing

Run a free plagiarism check in 10 minutes, generate accurate citations for free.

- Knowledge Base

- Starting the research process

- What Is Root Cause Analysis? | Definition & Examples

What Is Root Cause Analysis? | Definition & Examples

Published on January 6, 2023 by Tegan George . Revised on November 17, 2023.

Root cause analysis is a problem-solving approach that uses the analogy of roots and blooms to model cause-and-effect relationships. Rather than focusing on what’s above the surface, root cause analysis troubleshoots solutions to problems by analyzing what is causing them. Note Similarly to exploratory research , it’s important to remember that root cause analysis does not provide solutions to problems. Rather, it’s one method within a larger problem-solving landscape.

Root cause analysis is a form of quality management, often used in organizational management, quality control, and in healthcare fields like nursing. Root cause analysis can be a helpful study tool for students, too, when used for brainstorming or memorization exercises.

Table of contents

Root cause analysis template, the “5 whys” of root cause analysis, advantages and disadvantages of root cause analysis, other interesting articles, frequently asked questions.

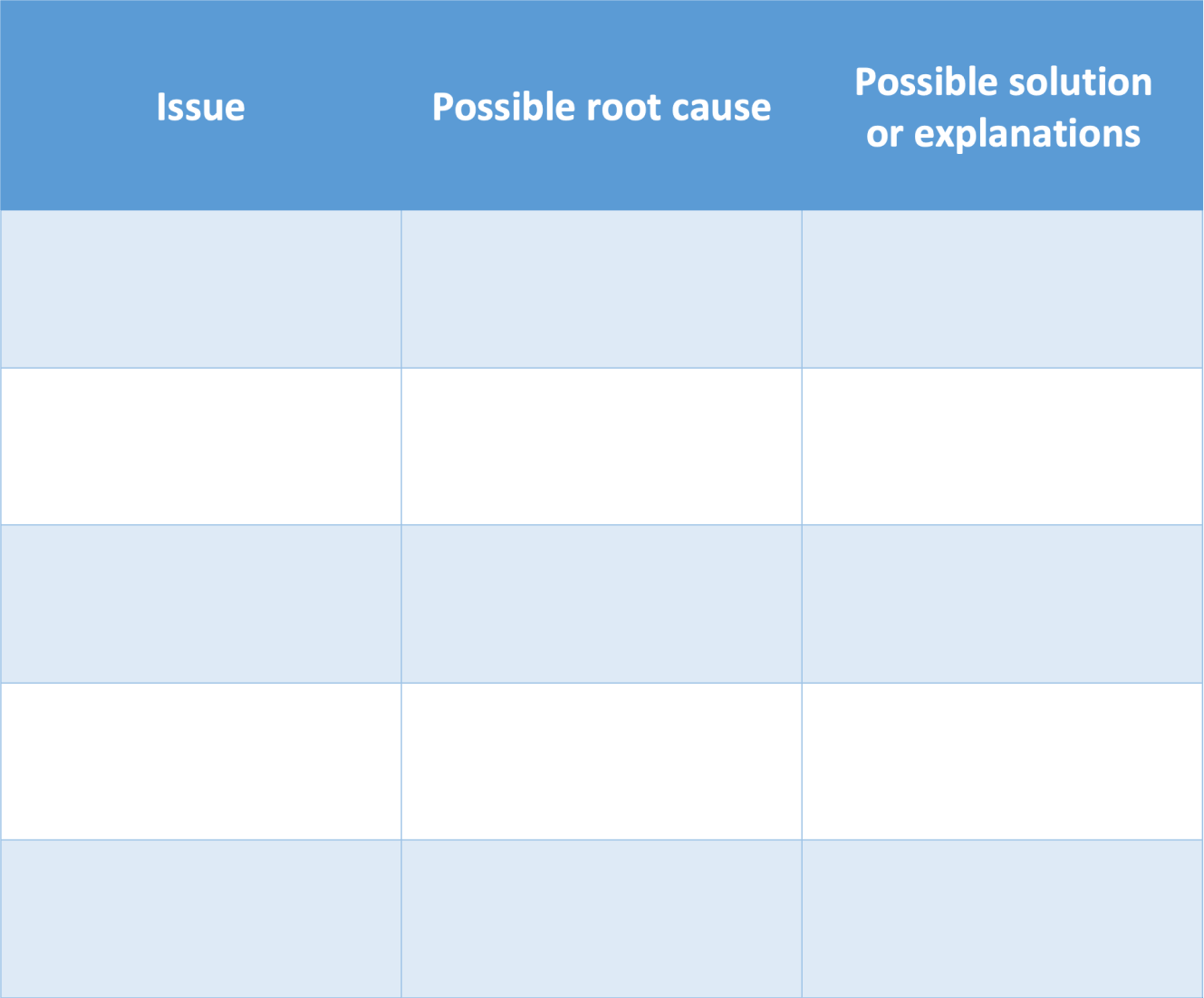

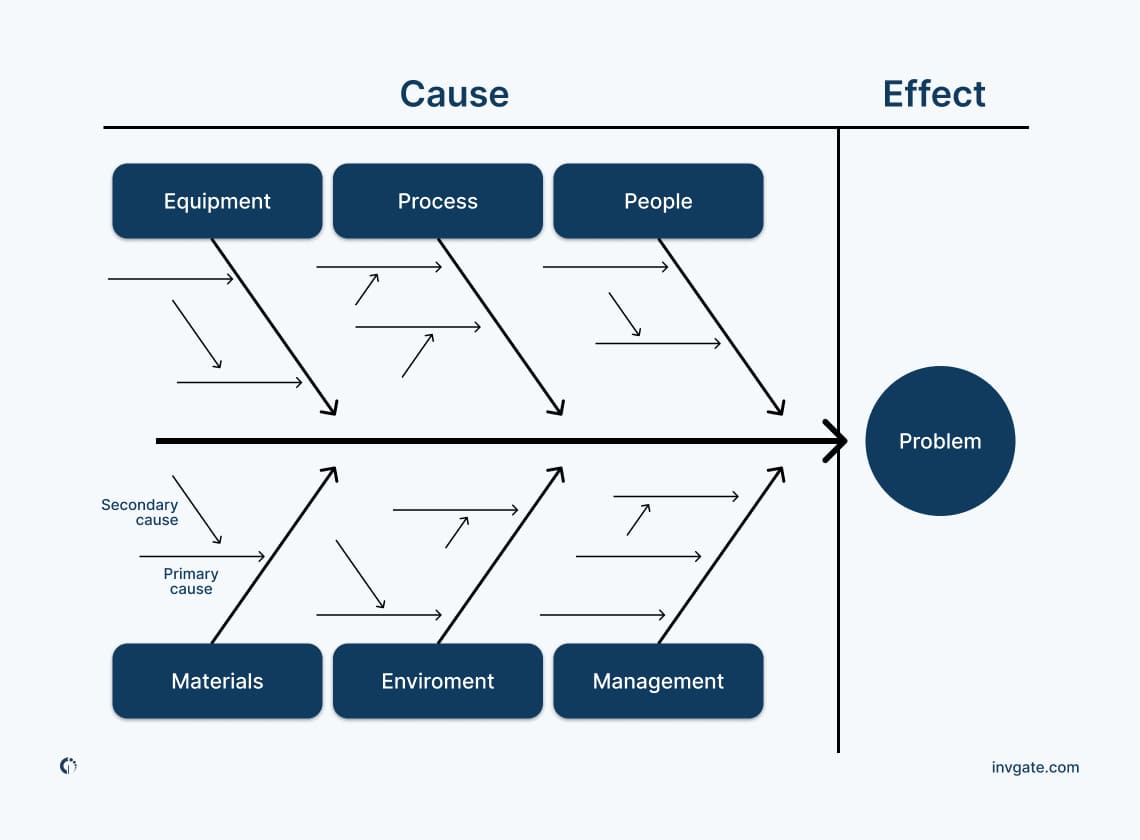

It’s easy to draw root cause analysis charts by hand, on a whiteboard or a big piece of paper. Many people use fishbone diagrams as well, or you can download our template below.

Here's why students love Scribbr's proofreading services

Discover proofreading & editing

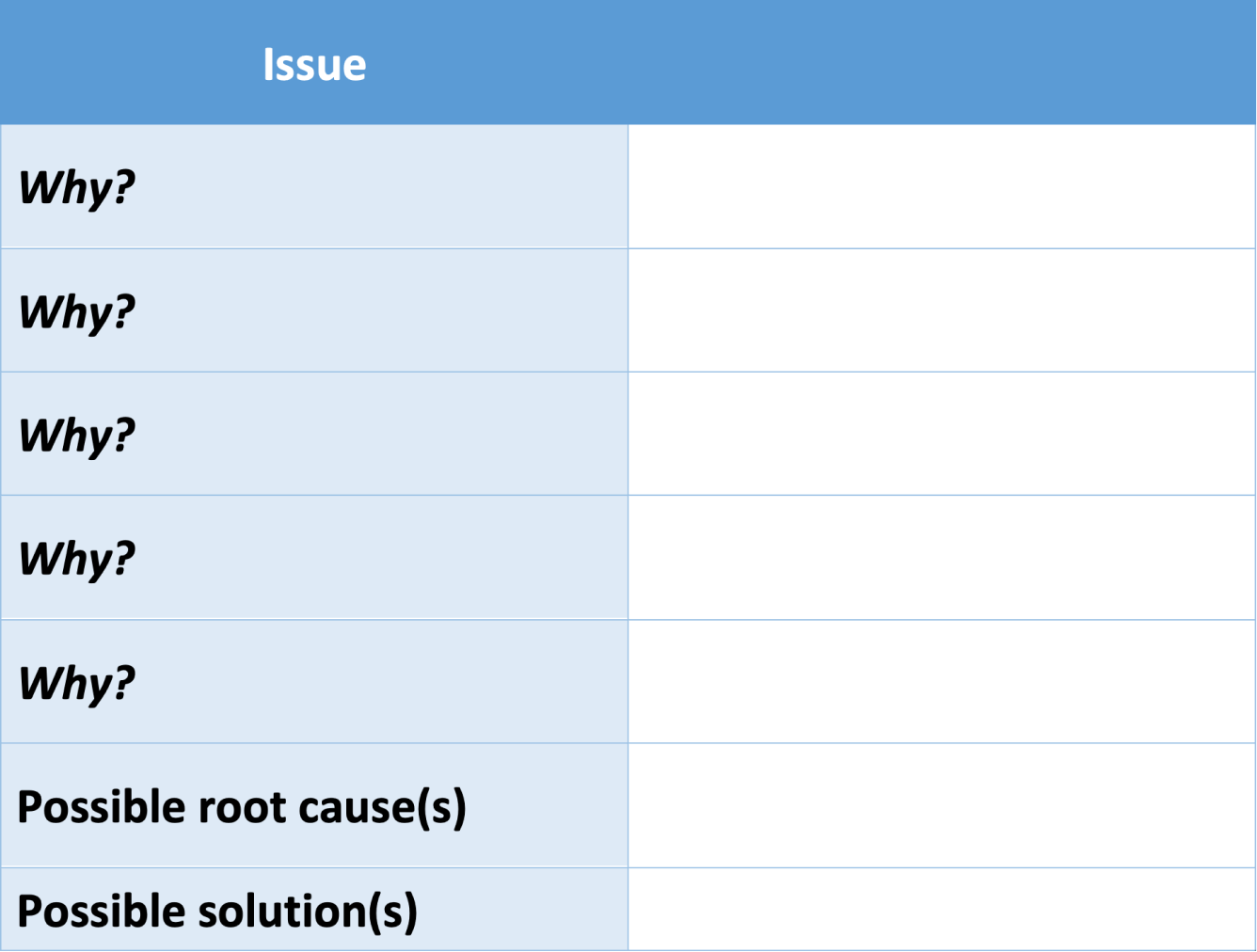

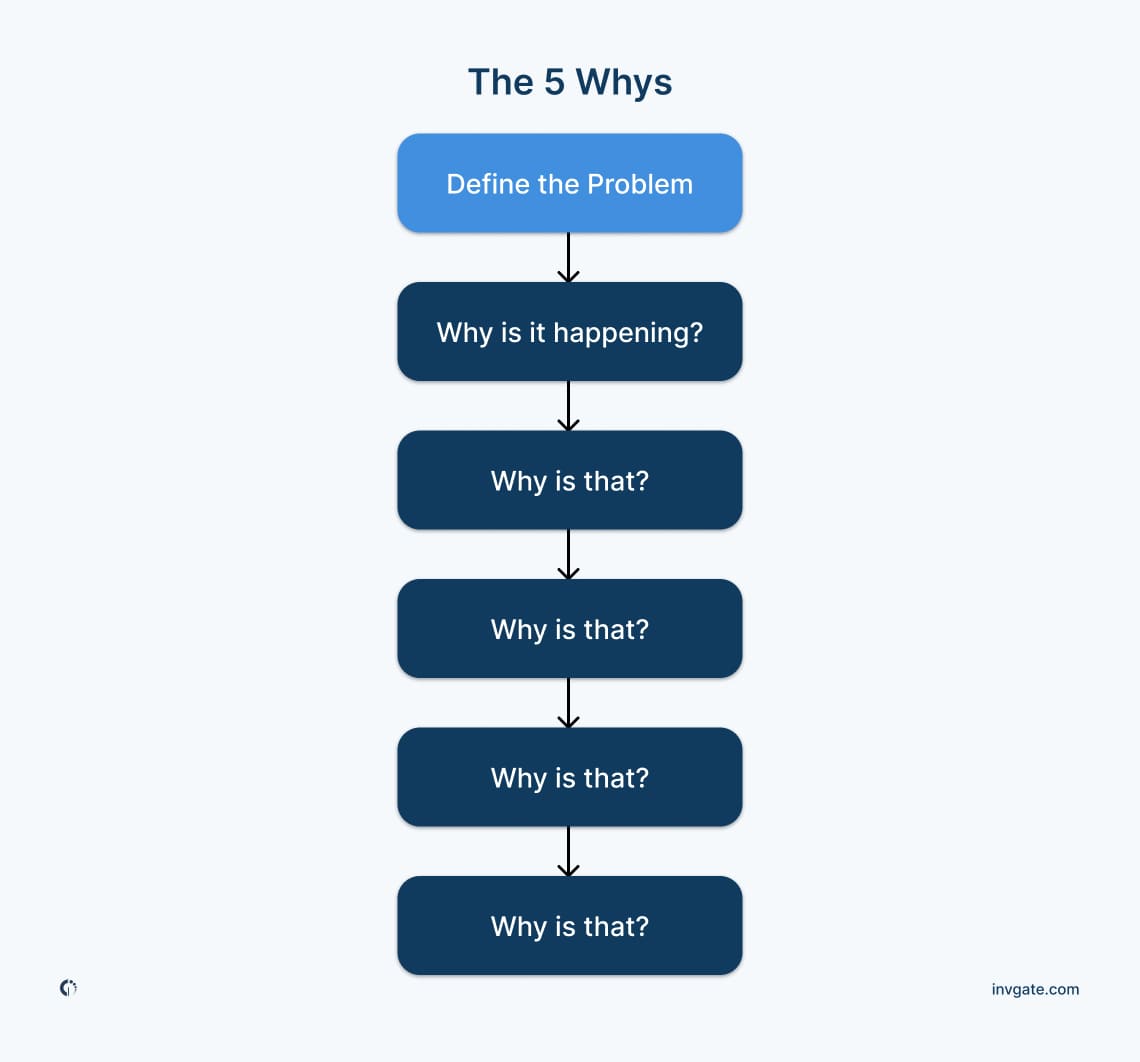

One of the most common ways to conduct root cause analysis is using the “5 Whys” method, popular in lean management. The 5 Whys are an interconnected method of analysis: after defining your problem, you ask “why?” and answer as concisely as possible. The first “why” often leads to the second, which leads to the third, etc.

In short, you continue to ask “why” until the answer provided is no longer a contributor to the broader issue, but a possible solution to that issue. In other words, as you strategize, you’ll sense it’s time to stop when a provided answer has the potential to stop the whole problem from occurring, rather than only one aspect of that problem. This often takes 3-5 “whys” but can definitely stretch out for longer.

You can use this template to map out your whys.

Root cause analysis is a great way to organize your thoughts, but its simplicity leads to a few downsides.

- Great brainstorming tool for individual or group projects.

- Can help identify causal relationships and clarify relationships between variables .

- “5 whys” system can help simplify complex issues and drive possible solutions.

Disadvantages

- Can be overly simplistic, not leaving much room for nuance or variations.

- Path dependence can occur if the wrong question is asked, leading to incorrect conclusions.

- Cannot provide answers, only suggestions, so best used in the exploratory research phase .

If you want to know more about the research process , methodology , research bias , or statistics , make sure to check out some of our other articles with explanations and examples.

Methodology

- Sampling methods

- Simple random sampling

- Stratified sampling

- Cluster sampling

- Likert scales

- Reproducibility

Statistics

- Null hypothesis

- Statistical power

- Probability distribution

- Effect size

- Poisson distribution

Research bias

- Optimism bias

- Cognitive bias

- Implicit bias

- Hawthorne effect

- Anchoring bias

- Explicit bias

Prevent plagiarism. Run a free check.

There are several common tools used for root cause analysis , the most popular of which include fishbone diagrams , scatterplots, and the “5 whys.”

A fishbone diagram is a method that can be used to conduct root cause analysis.

Cite this Scribbr article

If you want to cite this source, you can copy and paste the citation or click the “Cite this Scribbr article” button to automatically add the citation to our free Citation Generator.

George, T. (2023, November 17). What Is Root Cause Analysis? | Definition & Examples. Scribbr. Retrieved April 9, 2024, from https://www.scribbr.com/research-process/root-cause-analysis/

Is this article helpful?

Tegan George

Other students also liked, what is a fishbone diagram | templates & examples, how to write a problem statement | guide & examples, how to define a research problem | ideas & examples, unlimited academic ai-proofreading.

✔ Document error-free in 5minutes ✔ Unlimited document corrections ✔ Specialized in correcting academic texts

- Teaching & Learning Home

- Becoming an Educator

- Become a Teacher

- California Literacy

- Career Technical Education

- Business & Marketing

- Health Careers Education

- Industrial & Technology Education

- Standards & Framework

- Work Experience Education (WEE)

- Curriculum and Instruction Resources

- Common Core State Standards

- Curriculum Frameworks & Instructional Materials

- Distance Learning

- Driver Education

- Multi-Tiered System of Supports

- Recommended Literature

- School Libraries

- Service-Learning

- Specialized Media

- Grade Spans

- Early Education

- P-3 Alignment

- Middle Grades

- High School

- Postsecondary

- Adult Education

- Professional Learning

- Administrators

- Curriculum Areas

- Professional Standards

- Quality Schooling Framework

- Social and Emotional Learning

- Subject Areas

- Computer Science

- English Language Arts

- History-Social Science

- Mathematics

- Physical Education

- Visual & Performing Arts

- World Languages

- Testing & Accountability Home

- Accountability

- California School Dashboard and System of Support

- Dashboard Alternative School Status (DASS)

- Local Educational Agency Accountability Report Card

- School Accountability Report Card (SARC)

- State Accountability Report Card

- Compliance Monitoring

- District & School Interventions

- Awards and Recognition

- Academic Achievement Awards

- California Distinguished Schools Program

- California Teachers of the Year

- Classified School Employees of the Year

- California Gold Ribbon Schools

- Assessment Information

- CA Assessment of Student Performance and Progress (CAASPP)

- CA Proficiency Program (CPP)

- English Language Proficiency Assessments for CA (ELPAC)

- Grade Two Diagnostic Assessment

- High School Equivalency Tests (HSET)

- National Assessment of Educational Progress (NAEP)

- Physical Fitness Testing (PFT)

- Smarter Balanced Assessment System

- Finance & Grants Home

- Definitions, Instructions, & Procedures

- Indirect Cost Rates (ICR)

- Standardized Account Code Structure (SACS)

- Allocations & Apportionments

- Categorical Programs

- Consolidated Application

- Federal Cash Management

- Local Control Funding Formula

- Principal Apportionment

- Available Funding

- Funding Results

- Projected Funding

- Search CDE Funding

- Outside Funding

- Funding Tools & Materials

- Finance & Grants Other Topics

- Fiscal Oversight

- Software & Forms

- Data & Statistics Home

- Accessing Educational Data

- About CDE's Education Data

- About DataQuest

- Data Reports by Topic

- Downloadable Data Files

- Data Collections

- California Basic Educational Data System (CBEDS)

- California Longitudinal Pupil Achievement Data System (CALPADS)

- Consolidated Application and Reporting System (CARS)

- Cradle-to-Career Data System

- Annual Financial Data

- Certificated Salaries & Benefits

- Current Expense of Education & Per-pupil Spending

- Data Governance

- Data Privacy

- Educational Data Governance (EDGO)

- Student Health & Support

- Free and Reduced Price Meal Eligibility Data

- Food Programs

- Data Requests

- School & District Information

- California School Directory

- Charter School Locator

- County-District-School Administration

- Private School Data

- Public Schools and District Data Files

- Regional Occupational Centers & Programs

- School Performance

- Postsecondary Preparation

- Specialized Programs Home

- Directory of Schools

- Federal Grants Administration

- Charter Schools

- Contractor Information

- Laws, Regulations, & Requirements

- Program Overview

- Educational Options

- Independent Study

- Open Enrollment

- English Learners

- Special Education

- Administration & Support

- Announcements & Current Issues

- Data Collection & Reporting

- Family Involvement & Partnerships

- Quality Assurance Process

- Services & Resources

- CA Equity Performance and Improvement Program

- Improving Academic Achievement

- Schoolwide Programs

- Statewide System of School Support (S4)

- Specialized Programs Other Topics

- American Indian

- Gifted & Talented Education

- Homeless Education

- Migrant/International

- Private Schools and Schooling at Home

- State Special Schools

- Learning Support Home

- Attendance Improvement

- School Attendance Review Boards

- Expanded Learning

- 21st Century Community Learning Centers

- After School Education & Safety Program

- Expanded Learning Opportunities Program

- Child Nutrition Information & Payment System (CNIPS)

- Rates, Eligibility Scales, & Funding

- School Nutrition

- Parents/Family & Community

- Clearinghouse for Multilingual Documents

- School Disaster and Emergency Management

- Learning Support Other Topics

- Class Size Reduction

- Education Technology

- Educational Counseling

- Mental Health

- Safe Schools

- School Facilities

- Transportation

- Youth Development

- Professional Learning Home

- Title II, Part A Resources and Guidance

- Specialized Programs

- Title I: Improving Academic Achievement

- Title I, Part A

Needs Assessment and Root Cause Analysis FAQs

These FAQs are intended to introduce local educational agencies (LEAs) to needs assessments and root cause analysis. This collection represents commonly asked questions, but is not intended to be a complete list of all possible questions.

Needs Assessment | Root Cause Analysis | Back to Continuous Improvement Resources

Expand All | Collapse All

Needs Assessment

What is a needs assessment.

A needs assessment is a tool used to identify a school’s and/or LEA’s strengths, weaknesses, and the areas in which improvement is needed. A needs assessment is sometimes called:

- Comprehensive Needs Assessment (CNA)

- Segmented Needs Assessment (SNA)

- Consolidated Needs Assessment

- Equity audit

- School Quality Review (SQR)

- Diagnostic assessment

- Diagnostic review

- Diagnostic inquiry

What is a needs assessment for improvement?

A needs assessment for improvement is a systemic process that is used to:

- Determine strengths and weaknesses of a school and/or LEA

- Understand the context and constraints of the school and/or LEA

- Perform a root-cause analysis

- Develop an improvement plan outlining changes considered most likely to bolster or build on strengths and to remediate weaknesses

- Be part of an ongoing continuous improvement cycle that includes both long-range performance goals and short-cycle implementation targets, and

- Include questions at the county office of education level, even if the focus is the LEA level

Why is a needs assessment important?

How do you know what kind of needs assessment to use.

A needs assessment is a point-in-time snapshot. Examples include:

- Comprehensive Needs Assessment–assessing all aspects of the district and its context (including its county office of education), and/or

- Segmented Needs Assessment–assessing only one or a few aspects of the district and its context.

Back to Top

Root Cause Analysis

Why is root cause analysis important.

Root cause analysis addresses the problem , rather than the symptom , eliminates wasted effort, conserves resources, and informs strategy selection.

- The California School Dashboard identifies symptoms of the problem. The problem causing those symptoms is revealed through root cause analysis.

What is root cause analysis?

Root cause analysis is part of the needs assessment process. It is a strategy to thoroughly examine practices, processes, and routines to determine their impact on outcomes. It answers the “Why?” behind each identified area of improvement.

- Root cause is defined as “the deepest underlying cause or causes of positive or negative symptoms within any process that, if dissolved, would result in elimination or substantial reduction of the symptom” (Preuss, 2003, p. 3).

Where does root cause analysis fit into the Continuous Improvement process?

Root cause analysis occurs:

- After gathering and analyzing data

- Before determining findings and creating action plans

Where does root cause analysis fit into the Local Control and Accountability Plan (LCAP) process?

- After gathering and analyzing data through the needs assessment process

- Before determining Actions and Services for the LCAP

Who participates in root cause analysis?

Representatives from all stakeholder groups can participate in root cause analysis and may include:

- California Department of Education personnel

- County offices of education personnel

- District personnel

- Local boards of education

- Families and community members

- School personnel

- District-hired external partners

What tools are available for root cause analysis?

Examples of some promising root cause analysis tools include:

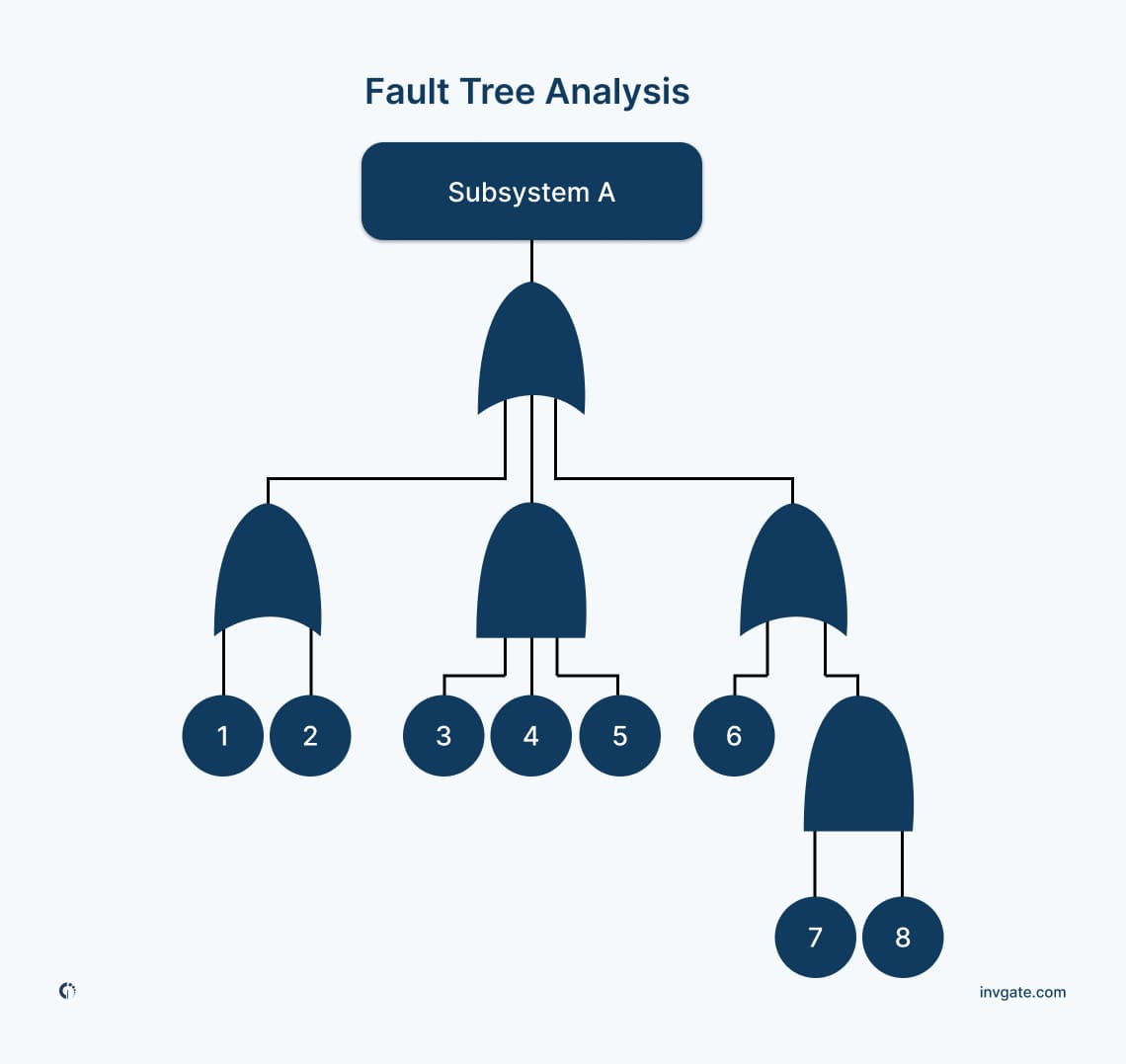

- Fishbone Diagram (using the 5 Whys)

- Interrelationship Digraph

- Expert Convening

- Empathy Interviews

- Digging Into Data

- Process Mapping

- Driver Diagram

Preuss, P. 2003. Root Cause Analysis: School Leader’s Guide to Using Data to Dissolve Problems. New York: Routledge.

- Targeted/Additional Targeted Support & Improvement

- Title I Improving Academic Achievement

- Comprehensive Support and Improvement

- Title I, Part A Authorized Use of Funds

- ESSA Assistance Status Data Files

- Title I, Part A Parent and Family Engagement

- California's System of Support

- Title I, Part A Schoolwide Program

- Title I, Part A School Allocations

- ATSI Planning Summary

- FY 2023–24 GMART CSI LEA Reporting Instructions (added 02-Apr-2024) removed by RO --> Grant Management and Reporting Tool (GMART) instructions for local educational agencies (LEAs) with schools that meet the criteria for Comprehensive Support and Improvement (CSI) for Fiscal Year (FY) 2023–24. removed by RO -->

- Black Student Achievement (added 08-Mar-2024) removed by RO --> Information and resources for local educational agencies (LEAs) and educational partners to support academic achievement for Black/African American students. removed by RO -->

- ESSA CSI COE Subgrant Closeout (added 29-Feb-2024) removed by RO --> Information regarding the Every Student Succeeds Act (ESSA) Comprehensive Support and Improvement (CSI) county offices of education (COEs) Subgrant Closeout Timeline, Instructions, and Resources. removed by RO -->

- Business Essentials

- Leadership & Management

- Credential of Leadership, Impact, and Management in Business (CLIMB)

- Entrepreneurship & Innovation

- *New* Digital Transformation

- Finance & Accounting

- Business in Society

- For Organizations

- Support Portal

- Media Coverage

- Founding Donors

- Leadership Team

- Harvard Business School →

- HBS Online →

- Business Insights →

Business Insights

Harvard Business School Online's Business Insights Blog provides the career insights you need to achieve your goals and gain confidence in your business skills.

- Career Development

- Communication

- Decision-Making

- Earning Your MBA

- Negotiation

- News & Events

- Productivity

- Staff Spotlight

- Student Profiles

- Work-Life Balance

- Alternative Investments

- Business Analytics

- Business Strategy

- Business and Climate Change

- Design Thinking and Innovation

- Digital Marketing Strategy

- Disruptive Strategy

- Economics for Managers

- Entrepreneurship Essentials

- Financial Accounting

- Global Business

- Launching Tech Ventures

- Leadership Principles

- Leadership, Ethics, and Corporate Accountability

- Leading with Finance

- Management Essentials

- Negotiation Mastery

- Organizational Leadership

- Power and Influence for Positive Impact

- Strategy Execution

- Sustainable Business Strategy

- Sustainable Investing

- Winning with Digital Platforms

Root Cause Analysis: What It Is & How to Perform One

- 07 Mar 2023

The problems that affect a company’s success don’t always result from not understanding how to solve them. In many cases, their root causes aren’t easily identified. That’s why root cause analysis is vital to organizational leadership .

According to research described in the Harvard Business Review , 85 percent of executives believe their organizations are bad at diagnosing problems, and 87 percent think that flaw carries significant costs. As a result, more businesses seek organizational leaders who avoid costly mistakes.

If you’re a leader who wants to problem-solve effectively, here’s an overview of root cause analysis and why it’s important in organizational leadership.

Access your free e-book today.

What Is Root Cause Analysis?

According to the online course Organizational Leadership —taught by Harvard Business School professors Joshua Margolis and Anthony Mayo— root cause analysis is the process of articulating problems’ causes to suggest specific solutions.

“Leaders must perform as beacons,” Margolis says in the course. “Namely, scanning and analyzing the landscape around the organization and identifying current and emerging trends, pressures, threats, and opportunities.”

By working with others to understand a problem’s root cause, you can generate a solution. If you’re interested in performing a root cause analysis for your organization, here are eight steps you must take.

8 Essential Steps of an Organizational Root Cause Analysis

1. identify performance or opportunity gaps.

The first step in a root cause analysis is identifying the most important performance or opportunity gaps facing your team, department, or organization. Performance gaps are the ways in which your organization falls short or fails to deliver on its capabilities; opportunity gaps reflect something new or innovative it can do to create value.

Finding those gaps requires leveraging the “leader as beacon” form of leadership.

“Leaders are called upon to illuminate what's going on outside and around the organization,” Margolis says in Organizational Leadership , “identifying both challenges and opportunities and how they inform the organization's future direction.”

Without those insights, you can’t reap the benefits an effective root cause analysis can produce because external forces—including industry trends, competitors, and the economy—can affect your company’s long-term success.

2. Create an Organizational Challenge Statement

The next step is writing an organizational challenge statement explaining what the gap is and why it’s important. The statement should be three to four sentences and encapsulate the challenge’s essence.

It’s crucial to explain where your organization falls short, what problems that poses, and why it matters. Describe the gap and why you must urgently address it.

A critical responsibility is deciding which gap requires the most attention, then focusing your analysis on it. Concentrating on too many problems at once can dilute positive results.

To prioritize issues, consider which are the most time-sensitive and mission-critical, followed by which can make stakeholders happy.

3. Analyze Findings with Colleagues

It's essential to work with colleagues to gain different perspectives on a problem and its root causes. This involves understanding the problem, gathering information, and developing a comprehensive analysis.

While this can be challenging when you’re a new organizational leader, using the double helix of leadership —the coevolutionary process of executing organizational leadership's responsibilities while developing the capabilities to perform them—can help foster collaboration.

Research shows diverse ideas improve high-level decision-making, which is why you should connect with colleagues with different opinions and expertise to enhance your root cause analysis’s outcome.

4. Formulate Value-Creating Activities

Next, determine what your company must do to address your organizational challenge statement. Establish three to five value-creating activities for your team, department, or organization to close the performance or opportunity gap you’ve identified.

This requires communicating organizational direction —a clear and compelling path forward that ensures stakeholders know and work toward the same goal.

“Setting direction is typically a reciprocal process,” Margolis says in Organizational Leadership . “You don't sit down and decide your direction, nor do you input your analysis of the external context into a formula and solve for a direction. Rather, setting direction is a back-and-forth process; you move between the value you'd like to create for customers, employees, investors, and your grasp of the context.”

5. Identify Necessary Behavior Changes

Once you’ve outlined activities that can provide value to your company, identify the behavior changes needed to address your organizational challenge statement.

“Your detective work throughout your root cause analysis exposes uncomfortable realities about employee competencies, organizational inefficiencies, departmental infighting, and unclear direction from leadership at multiple levels of the company,” Mayo says in Organizational Leadership .

Factors that can affect your company’s long-term success include:

- Ineffective communication skills

- Resistance to change

- Problematic workplace stereotypes

Not all root cause analyses reveal behaviors that must be eliminated. Sometimes you can identify behaviors to enhance or foster internally, such as:

- Collaboration

- Innovative thinking

- Creative problem-solving

6. Implement Behavior Changes

Although behaviors might be easy to pinpoint, putting them into practice can be challenging.

To ensure you implement the right changes, gauge whether they’ll have a positive or negative impact. According to Organizational Leadership , you should consider the following factors:

- Motivation: Do the people at your organization have a personal desire for and commitment to change?

- Competence: Do they have the skills and know-how to implement change effectively?

- Coordination: Are they willing to work collaboratively to enact change?

Based on your answers, decide what behavior changes are plausible for your root cause analysis.

7. Map Root Causes

The next step in your analysis is mapping the root causes you’ve identified to the components of organizational alignment. Doing so helps you determine which components to adjust or change to implement employee behavior changes successfully.

Three root cause categories unrelated to behavior changes are:

- Systems and structures: The formal organization component, including talent management, product development, and budget and accountability systems

- People: Individuals’ profiles and the workforce’s overall composition, including employees’ skills, experience, values, and attitudes

- Culture: The informal, intangible part of your organization, including the norms, values, attitudes, beliefs, preferences, common practices, and habits of its employees

8. Create an Action Plan

Using your findings from the previous steps, create an action plan for addressing your organizational problem’s root cause and consider your role in it.

To make the action plan achievable, ensure you:

- Identify the problem’s root cause

- Create measurable results

- Ensure clear communication among your team

“One useful way to assess your potential impact on the challenge is to understand your locus of control,” Mayo says in Organizational Leadership , “or the extent to which you can personally drive the needed change or improvement.”

The best way to illustrate your control is by using three concentric circles: the innermost circle being full control of resources, the middle circle representing your ability to influence but not control, and the outermost circle alluding to shifts outside both your influence and control.

Consider these circles when implementing your action plan to ensure your goals don’t overreach.

The Importance of Root Cause Analysis in Organizational Leadership

Root cause analysis is a critical organizational leadership skill for effectively addressing problems and driving change. It helps you understand shifting conditions around your company and confirm that your efforts are relevant and sustainable.

As a leader, you must not only effect change but understand why it’s needed. Taking an online course, such as Organizational Leadership , can enable you to gain that knowledge.

Using root cause analysis, you can identify the issues behind your organization’s problems, develop a plan to address them, and make impactful changes.

Are you preparing to transition to a new leadership role? Enroll in our online certificate course Organizational Leadership —one of our leadership and management courses —and learn how to perform an effective root cause analysis to ensure your company’s long-term success. To learn more about what it takes to be an effective leader, download our free leadership e-book .

About the Author

An official website of the United States government

The .gov means it's official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you're on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

- Publications

- Account settings

- Browse Titles

NCBI Bookshelf. A service of the National Library of Medicine, National Institutes of Health.

StatPearls [Internet]. Treasure Island (FL): StatPearls Publishing; 2024 Jan-.

StatPearls [Internet].

Root cause analysis and medical error prevention.

Gunjan Singh ; Raj H. Patel ; Joshua Boster .

Affiliations

Last Update: May 30, 2023 .

- Continuing Education Activity

The term "medical error" encompasses diverse events that vary in magnitude and can potentially harm the patient. According to the 2019 World Health Organization (WHO) Patient Safety Factsheet, adverse events due to unsafe patient care are among the top 10 causes of death and disability worldwide. However, it is essential to understand that healthcare delivery involves multiple variables in a dynamic environment, with many critical decisions made quickly. As such, the healthcare system cannot implement rigid protocols used by other high-risk industries, such as aviation. Reducing medical errors requires a multifaceted approach at various levels of healthcare. In the event of a sentinel occurrence or adverse patient outcomes, a thorough evaluation is warranted to prevent such events. Root cause analyses provide a method of evaluation for these situations so that a system-based intervention can be implemented rather than blaming individual providers. This activity reviews the root cause analysis process in medical error prevention. The course highlights the interprofessional team's role in performing this analysis to prevent medical errors and improve clinical outcomes.

- Demonstrate effective root cause analysis of a sentinel event and implement strategies for its prevention.

- Apply root cause analysis reporting standards in accordance with the Joint Commission requirements.

- Identify the indications for reporting sentinel events to the Joint Commission and the steps that should be taken following the occurrence of such incidents.

- Collaborate within an interprofessional team to prevent the most common types of clinical errors and improve clinical outcomes.

- Introduction

Medical error is an unfortunate reality of the healthcare industry and a topic that is continuously discussed due to its grave impact on patient care and outcomes. In a 1999 publication by the Institute of Medicine (IOM), it was highlighted that deaths resulting from medical error exceeded those attributed to motor vehicle accidents, breast cancer, or AIDS. [1]

Subsequent reports that discuss potential etiologies of medical errors have blamed systemic issues. Others have focused attention on certain groups of patients that may be more vulnerable to medical error than others. [2] [3] Recently, the impact of medical errors on patient family members and healthcare professionals has been emphasized due to its effects on exacerbating burnout, poor work performance, mental health decline, and even suicidality. [4] [5]

Though it may be challenging to pinpoint the definitive cause of medical error in certain situations, it is important to evaluate strategies that can be used to mitigate and prevent these adverse events from occurring in the first place. One such method is root cause analysis, which has been previously shown to reduce clinical and surgical errors in various specialties by establishing a quality improvement framework. [6] This article will discuss the application of root cause analysis in medical error prevention and strategies for maintaining continuous quality improvement in the healthcare setting.

The Institute of Medicine defines a medical error as "the failure of a planned action to be completed as intended or the use of a wrong plan to achieve an aim." [1] It is essential to recognize the differences between medical malpractice and medical error. An adverse event in a healthcare setting may be attributed to medical error while not meeting the threshold of malpractice or negligence. Medical errors generally result from the improper execution of a plan or improper planning of a method of execution. Medical errors can also occur during preventative care measures, for example, if a provider overlooks a patient's allergy when administering medication. Thus, the complexity of the occurrence of a medical error can range widely and manifest in any aspect of patient care, from admission to discharge and in the outpatient setting. It is essential to recognize that medical errors may occur without causing direct harm to the patient. Regardless, it is critical to evaluate the cause of all medical errors, whether or not the patient is harmed, and develop guidelines and strategies to prevent future occurrences.

If medical errors harm the patient, they are classified as preventable adverse events or sentinel events. Sentinel events are preventable adverse outcomes that warrant urgent investigation to determine the cause of the error. [7] These events are not only debilitating to patients but can also impact the livelihood of healthcare providers. It is important to note that sentinel events are unrelated to the patient's underlying medical condition and are attributable to improper medical intervention or improper technique. If a patient receives medication and experiences an anaphylactic reaction, it must be determined whether the reaction was due to the medication itself or the provider's failure to review the patient's allergies before administration. Thus, these cases must be critically reviewed to delineate whether or not the etiology of the error was preventable, which is often a challenging task.

Root cause analysis (RCA) is a process for identifying the causal factors underlying variations in performance. In the case of medical error, this variation in performance may result in a sentinel event. A standardized RCA process is mandated by the Joint Commission to identify the cause of medical errors and thus allow healthcare institutions to develop strategies to mitigate future errors. [7] Despite its wide adoption in the business, engineering, and industrial sectors, its use in the medical field has been limited. It is important to note that the RCA process aims not to assign individual blame but to identify lapses in system-level processes that can be restructured to prevent patient harm and reduce the likelihood of future sentinel events. Thus, identifying the root cause of a medical error can better direct the need for additional training and resources.

Applying Root Cause Analysis

For accreditation purposes, the Joint Commission requires that healthcare institutions have a comprehensive process for systematically analyzing sentinel events. The RCA process is one of the most commonly utilized tools for this purpose. Through the RCA process, healthcare institutions can optimize patient care and enact measures to mitigate adverse events that compromise patient safety. In addition to improving patient safety and quality metrics, an RCA's purpose includes optimizing process flow and outcomes.

RCA emphasizes lapses in system-level processes. It does not emphasize individual actions. A designated RCA team must be assembled to review and identify necessary changes at the systematic level that can improve performance and reduce the likelihood of a repeat sentinel event. [8] Failure to perform an RCA within 45 days of a sentinel event may result in the healthcare institution being placed on an 'accreditation watch,' which is public information. Repeat violations may result in an onsite review by the Joint Commission that may jeopardize accreditation. [9]

The first step of an RCA is to form an interprofessional team to analyze and define the problem. There should be a designated process to communicate with senior leadership throughout the journey while meeting deadlines internally and with the Joint Commission. After identifying the problem, the team should evaluate systematic factors that may have contributed to the error. Throughout the process, collecting data regarding the potential underlying causes is important. The team should propose and implement immediate changes so that a repeat sentinel event does not occur during the RCA process. Next, the team should evaluate the list of root causes and consider their interrelationships. During the RCA process, the team will explore risk-reduction and process improvement strategies to prevent future errors at the systematic level. After identifying process improvement strategies, the team must communicate with senior leadership and key stakeholders to evaluate whether the proposed process modifications are acceptable.

The Joint Commission has created a framework and series of 24 questions to aid in organizing an RCA. This framework should be utilized as a general template when preparing the RCA report that will eventually be submitted to the Joint Commission after thorough evaluation. The 24-question framework recommended by the Joint Commission considers various situational factors that may have contributed to a sentinel event. This includes examining the systematic process, human factors, equipment malfunctions, environmental factors, uncontrollable external factors, organizational factors, staffing and qualifications, contingency plans, performance expectations, informational disruptions, communication, environmental risks, training, and technology. [7]

With detailed consideration of each of these topics, an in-depth analysis of the cause of the sentinel event can occur. One factor that makes an appearance in several questions is communication. Communication within the team and with leadership is critical to maintaining organizational structure. It can be difficult to convey messages effectively and efficiently without proper communication systems. Environmental factors should also be examined to determine if any situational issues were ongoing at the time of the sentinel event that may have impacted the outcome. Staffing is another important topic that should be examined during an RCA review to determine if the staff were appropriately qualified, competent, and portioned for their assigned duties.

After discussion, evaluation, and analysis, corrective actions should be developed, identifying areas for targeted improvement. While utilizing the 24-question framework, it is important to always consider causative etiologies because it will help determine the specific area that can be restructured to reduce risk. The root cause analysis should be clear and precise while providing appropriate depth and scope.

The Joint Commission has identified a series of adverse events subject to their purview. Primarily, this would be a sentinel event that has resulted in death or permanent loss of function unrelated to any underlying medical conditions. Alternatively, a sentinel event can also be considered as one of the following, even if the event did not cause death or severe harm:

- Patient suicide of any patient receiving care (including emergency department care), treatment, or services within the healthcare setting or 72 hours following their discharge

- Full-term infant having an unanticipated death

- An infant discharged to the wrong family

- Abduction of any patient receiving care, treatment, or services

- Elopement of a patient within a healthcare setting, leading to their harm

- Hemolytic transfusion reaction requiring administration of blood products

- Rape, assault, or homicide of anyone on scene at the healthcare premises

- Wrong patient, site, or procedure for all invasive procedures, including surgery

- Unintended retention of a foreign body in a patient following surgery

- Severe neonatal hyperbilirubinemia

- Prolonged fluoroscopy with cumulative dose to the wrong body region

- Fire, flame, or unanticipated smoke, heat, or flashes during patient care

- Intrapartum maternal death

- Severe maternal morbidity

The finalized RCA report must follow a set standard to meet the Joint Commission's requirement. It must include the following:

- Participation of the organization's leadership and key stakeholders involved in the process/system under review

- Thorough explanation of all findings

- Consideration of any relevant or applicable literature

- Internal accuracy and consistency, without contradictions or unanswered questions

Case Illustrations with RCA Interventions

Case Example 1

A 42-year-old primigravida woman at 34 weeks gestation was brought to the obstetric emergency department at midnight with complaints of severe headache, blurry vision, and right upper quadrant pain for the last 5 to 6 hours. She noted gradually increasing lower extremity edema and facial swelling as well. She has a history of gestational hypertension and was prescribed labetalol 200 mg twice a day a week before this presentation. On initial evaluation, her blood pressure was 190/110 mm Hg on 2 separate occasions, 5 minutes apart. She had gained 2 kilograms since her last antenatal checkup in the clinic a week ago.

The patient was diagnosed with severe preeclampsia. The senior obstetric resident ordered a loading dose of magnesium sulfate to prevent imminent seizure. The hospital protocol used an intravenous (IV) and intramuscular (IM) regimen where the patient receives a 4-gram (20% concentration) intravenous solution bolus and a 10-gram intramuscular dose (50% concentration) administered as 5 grams in each buttock. The senior resident verbally provided the order for magnesium sulfate administration to the junior resident, who subsequently verbally communicated the order to the nurse.

This magnesium sulfate dosing regimen is complex, with multiple doses in different locations, and was incorrectly prepared by the nurse who felt rushed in an urgent situation. A chart displaying magnesium sulfate's preparation in the drug preparation room was present but had become faded. Therefore the nurse prepared the medication relying on her memory. Before administering the medicine to the patient, as a part of the protocol, she repeated the dose strength aloud to another nurse, who cross-checked it from a printed chart and picked up the error in time. The senior resident also identified the error as the dose was communicated aloud and stopped administering the drug.

RCA with Corrective Measures

A root cause analysis was performed, and measures were taken to avoid this problem in the future. Magnesium sulfate was marked as a high-alert medication, as the Institute of Safe Medication Practices recommended. Furthermore, premixed solutions prepared by the pharmacy for the bolus dosing were instituted instead of requiring nurses to mix this high-risk medication on the unit. The second nurse verification measure was retained, with the second nurse instructed to double-check all doses, pump settings, drug names, and concentrations before administration of any drugs.

Moreover, the RCA recommended that all medication orders be provided in writing and/or entered in the electronic medical record using computerized provider order entry (CPOE) systems, regardless of the urgency of the situation, to avoid any dosing errors. The RCA team emphasized that verbal communication for medication administration should always be avoided. If verbal communications are necessary or unavoidable, the RCA recommended that the nurse taking the order should read back the order given to the prescribing physician to minimize any prescribing errors.

Case Example 2 (The name and date of birth used in this example are imaginative, used for illustrative purposes, and do not represent an actual patient. Any similarities, if noted, are purely coincidental.)

Anna Joy (date of birth October 30, 1991) was admitted to a busy obstetric ward. She was a primigravida woman at 30 weeks of gestation with complaints of intermittent cramping abdominal pain. She had come to visit her sister living in Boston from Spain. The patient's ability to communicate in English was limited, and she preferred speaking Spanish. However, her husband and sister were fluent in English and assisted with translation throughout the history, exam, and admission. The patient was seen by an obstetrician who advised routine investigations for threatened preterm labor and observation.

Another patient Ann Jay (date of birth September 30, 1991), was also admitted to the same obstetric ward. She was 34 weeks gestation and was admitted because of gestational diabetes mellitus with hyperglycemia. Her obstetrician advised an endocrinology referral, and the endocrinologist advised glucose monitoring and insulin administration. The nurse taking care of the patient was provided with the instructions, performed a finger-stick blood glucose check, and informed the endocrinologist about the results over the phone. The endocrinologist advised six units of regular insulin before lunch. The nurse also informed the obstetrician that the patient felt a decrease in fetal movements. The obstetrician advised ongoing observation and fetal kick counts.

The family members of the first patient, Anna Joy, informed the nurse that they were going to lunch. The morning shift nurse later required a half-day leave because of personal issues and quickly handed over her patients to another nurse. The ward was busy and running at full capacity. The new nurse decided to give the insulin injection first as the patient was about to receive her lunch. She did not know that Anna Joy preferred communication in Spanish. The nurse asked a few questions and rushed through patient identification with the help of two unique patient identifiers. She administered the insulin injection to the first patient and later realized it was supposed to be given to the second patient, Ann Jay. The attending obstetrician and the endocrinologist were informed. They took the necessary measures and closely monitored the patient for the next few hours. No inadvertent effects were noted.

A root cause analysis was performed, and measures were taken to avoid this problem in the future. The RCA team noted that the nurse caring for both patients had worked in the hospital for 5 years and was recently transitioned to the obstetric ward. This had never happened to her before. The team recognized that the modern patient care delivery process relies on the efficient and effective integration of an interprofessional care team. A clear, consistent, and standardized communication method between the team members contributes to safe patient care and minimizes the risk of adverse outcomes. The RCA team did not lay blame on the nurse involved. They instead instituted a standardized handoff platform and required all patient handoffs to occur using this format in the future. During shift change, the handoff between clinicians and nurses is pivotal in providing high-quality care. The aim should be to provide the oncoming team with up-to-date, accurate, and complete information. The RCA team outlined clinical education programs for nurses and clinicians to ensure high-quality and effective handoff occurs at every shift change and patient handoff.

They also instituted mandatory use of hospital-based interpreters when communicating with patients who are not fluent in English. The hospital procedure for verifying patient identification using two unique patient identifiers, the name and the date of birth, was retained. However, an additional mandatory step of verifying the patient's identity using an arm-band barcode was instituted before every medication administration. They also instituted the highlighting of patient charts and rooms when patients had similar names and dates of birth.

Case Example 3

A 26-year-old primigravida woman with labor pains was admitted to a busy hospital's labor and delivery suite at 39 weeks of gestation. There were no associated high-risk factors. The patient was admitted to the labor ward and managed according to routine protocol. She progressed in spontaneous labor, but the cardiotocograph showed prolonged fetal bradycardia lasting for 3 and a half minutes at 4 centimeters (cm) cervical dilatation. The fetal bradycardia did not resolve with initial conservative measures.

The patient was transferred to the operating room for a category one emergent cesarean section. A category one cesarean section means the baby should be delivered within 30 minutes of the procedure's decision. It is done when there is an immediate threat to the life of the mother or the baby. The baby was delivered in good condition, with no intraoperative complications. Before closure, the operating obstetrician asked the scrub nurse to perform a surgical count. The scrub nurse reported that there might be a missing gauze piece from the surgical trolley. The count was performed several times by the scrub and the floor nurse at this time. A second on-call obstetrician was called to assist the primary surgeon in checking for the surgical field's missing gauze piece.

The surgical gauze had a heat-bonded barium sulfate marker embedded in the fabric to assist with x-ray identification. An intraoperative x-ray was obtained to evaluate for intraperitoneal gauze, and the results were negative. The case was discussed with the department chief, and abdominal closure was performed. Due to the associated delays, the operative time was increased significantly (2 hours and 30 minutes).

An RCA of the event revealed that there were inconsistent practices regarding surgical count before the initiation of a procedure. Moreover, only one person (the scrub nurse) was charged with making this count. The RCA team highlighted that the surgical count is critical and must be performed in a standardized fashion to eliminate variation and minimize the possibility of human error. They highlighted international standards that recommend standardizing the counting process and systematically tracking the instruments, gauze, and sponges in the sterile field. They instituted World Health Organization's Surgical Safety Checklist as a mandatory step for all procedures regardless of the urgency of the procedure. They also recommended that the counting process be concurrently audible and visual to eliminate errors. The RCA recommended that the counting process should be performed by the scrub nurse and the circulating nurse independently, both before and after every procedure. They emphasized that the best practices for surgical count should always be followed regardless of the clinical situation.

Case Example 4

A 25-year-old man presented for bilateral LASIK surgery at a same-day surgery center. The operating surgeon examined the patient, a community-based surgeon who does not routinely operate at this facility. Informed consent was obtained by the operating surgeon preoperatively. The refractive error was -4 D for the right eye and – 5D for the left eye. The plan was to remove the refractive error altogether. There was a timeout to ensure the correct patient and procedure. The LASIK was started by making corneal flaps on both eyes, which was completed uneventfully. The second step was the excimer laser-guided corneal power correction.

The patient was adjusted on the operating microscope so that the first eye was directly under the excimer laser, and iris recognition was attempted. The machine did not recognize the iris pattern after 3 attempts. The surgeon decided to proceed without iris recognition. The technician thought that this was rare and that they had good iris recognition rates for this month (>98%). However, he did not want to contradict the surgeon.

Before the procedure, the circulating nurse noted that the patient's table was adjusted to the wrong side, and the left eye was under the laser instead of the right. She pressed the emergency stop button, and the treatment was terminated. After identifying the mistake, the surgeon and technician restarted the machine to treat the correct sequence's correct eyes.

Compared to unilateral procedures, bilateral procedures are especially challenging, particularly if the treatment varies between the 2 sides. An example is LASIK, where both eyes are typically corrected simultaneously, and there is no obvious pathology on the eye except for the refractive error. The correction is determined preoperatively, and the result is not immediately titrated. There is a significant chance for wrong-site procedures, given these ambiguities. To avoid this disaster, the RCA team implemented a verification procedure where the optometrist, technician, and surgeon were ALL required to verify each eye's refractive error before the procedure and after programming the laser.

Some advanced laser machines have an inbuilt layer of defense where the iris pattern of the eye is uniquely identified via iris recognition, which helps determine the correct eye and enhances the treatment fidelity. Some treatments, however, do not include iris recognition, and therefore the onus lies on the technicians, nurses, and surgeons to identify the appropriate eye correctly.

Case Example 5

A community clinic treats approximately 110 patients per day. The clinic is run by 2 primary care physicians, with the assistance of 2 nurses and scribes. A 10-year-old boy was brought to the clinic by his parents. The child had a runny nose for the last ten days. On examination, the primary care physician noted simple allergic rhinitis and advised them to use over-the-counter cetirizine. One of the scribes had called in sick that day, so a secretary was assisting the physician. The physician advised the parents that cetirizine is an over-the-counter medication, and they can go to their pharmacy of choice to obtain the medication. After 2 days, the patient's mother returned to the clinic and reported that the child was lethargic. The clinic's front desk stated that they would convey the information to the physician, who was very busy that day. The physician said it is typical for children taking cetirizine to be slightly sleepy. He said that they should inform the parents to ask the child to avoid going to school for the next few days. The message was conveyed to the mother.

The patient's mother, however, decided to take the child to another specialist as she was concerned regarding the sedation. At this visit, it was noted that the child was taking a 10-mg cetirizine tablet 2 times a day, which is higher than typically recommended.

An RCA review was performed at the primary clinic. It was noted that there was a typographical error in the instructions given to the patient, saying 10 mg twice a day instead of 5 mg twice a day, which the physician had intended. The RCA recommended a verification procedure for all prescription recommendations made during the clinic visit. They instituted verbal and written verification with the prescribing physicians of all drugs and doses transcribed by the scribes and/or office personnel to avoid this error in the future. The RCA team also recommended that the physician and the team should read prescription and over-the-counter drug recommendations with their intended doses to the patient/attendant in the clinic from the summary instructions and verify that it matches their notes.

The RCA also mandated a document review for all patient callbacks or return visits before any patient communication is made to avoid such errors in the future.

Case Example 6

All-Eyes Laser Center is a busy same-day ophthalmic laser center with multiple laser procedures being performed throughout the day. The center specializes in retinal and anterior segment lasers.

A 60-year-old man, JM, suffers from chronic angle-closure glaucoma and has been advised to undergo a YAG (Yttrium-Aluminum-Garnett) laser iridotomy. This procedure involves creating a small hole in the peripheral part of the iris to increase the aqueous flow between the anterior chamber and the posterior chamber to prevent a possible angle-closure attack and/or further glaucoma progression.

This was an unusually busy day at the laser center. The laser surgeon was running behind. There were 5 patients ahead of JM, and there was an anticipated delay of around 2 hours. As is the practice at the center, the nurse practitioner prepares the patients before the laser, and then the laser surgeon performs the procedure. The preparation involves checking the history, confirming the examination findings, and then instilling eye drops to prepare the procedure's eyes. This laser surgeon does 2 types of laser procedures. YAG iridotomy needs the eyes constricted with 2% pilocarpine eye drops, which ensures a good exposure of the peripheral iris crypts where the laser is directed to create a small iridotomy. The second procedure is a YAG capsulotomy. The posterior capsule in a pseudophakic eye is lasered to create an opening to counter an after-cataract posterior capsular opacity and improve vision. The YAG laser platform is a combined platform where both procedures can be performed with one machine.

The surgeon arrived at the laser suite and started the lasers. When JM's turn came, a proper timeout was confirmed, including the correct eye and procedure. However, when the patient was positioned at the laser machine, the surgeon noticed that the pupil was dilated rather than constricted. The surgeon again verified the patient's tag and name and the correct procedure. It was confirmed that the patient was indeed the correct one, and the procedure intended was YAG iridotomy. It would have been dangerous to attempt an iridotomy in a dilated pupil. The surgeon did not proceed with the procedure, and the patient was transferred out of the laser suite. The patient was counseled regarding the error and instructed that he would be rescheduled for the correct procedure in a few days. The error was misattributed to the nurse administering the wrong eye drop, secondary to high patient volume and practice inconsistencies.

A root cause analysis was performed, and measures were taken to avoid this problem in the future. This error did not result in harm to the patient. However, there is a significant chance of the wrong type of procedure being performed. Considering this, the RCA team recommended segregating patients for YAG capsulotomy and YAG iridotomy to different seating areas that were clearly labeled. The 2 eye drops, tropicamide and pilocarpine, were kept only in these areas, and the staff was not allowed to carry these drops out from the designated area. A barcode-based verification was also instituted to be used each time the drop was instilled.

There are precautions in place for similar-sounding medications and similar-sounding patient names. However, in a mixed clinic where multiple procedures are being performed with a relatively quick turnover, the pre-procedure medications can be mixed, especially if there is no designated 'bedside area' for the patient. Therefore using the precautions noted above can avoid incorrect medication administration.

- Issues of Concern

The IOM identifies medical errors as a leading cause of death and injury. [1] According to the 2019 World Health Organization (WHO) Patient Safety Factsheet, adverse events due to unsafe patient care are among the top ten causes of death and disability worldwide. Preventable adverse events in the United States of America (US) cause an estimated 44,000 to 98,000 hospital deaths annually. [1] This exceeds the number of deaths attributable to motor vehicle accidents and is estimated to cost the community between 37.6 to 50 billion dollars in terms of added health care cost, disability, and loss of productivity. [1]

Patients and their families face the most critical and severe consequences of medical errors. Therefore, identifying system processes that lead to medical errors and implementing corrective measures is the primary goal in treating this problem. An RCA and response can help identify system-based measures that can minimize the risk of adverse events and improve clinical outcomes.

Types of Medical Errors

It is essential to recognize that medical errors constitute diverse events. The "error" is not always a human miscalculation or miscommunication, as outlined by the cases above. Some errors are inherent to clinical situations, such as patient falls in hospital settings and healthcare-associated infections. The commonly recognized "types" of medical errors are outlined below.

- Medication error is widely accepted as the most common and preventable cause of patient injury. [10] Medication errors include giving the wrong drug or dose, via the wrong route, at an incorrect time, or to the wrong patient. The reported incidence of medication error-associated adverse events in acute hospitals is around 6.5 per 100 admissions. [10] Medication errors in the peri-discharge from an acute care facility are the most easily overlooked or missed errors. [10]

- Another common medical error is a diagnostic error with failure to correctly identify the cause of the clinical condition promptly. [10] Diagnostic errors are "missed opportunities to make a correct or timely diagnosis based on the available evidence, regardless of patient harm." [11]

- In hospitalized patients, wound infections, pressure ulcers, falls, healthcare-associated infections, and technical complications constitute another group of preventable medical errors. [10]

- The most common systems-error is failure to disseminate drug knowledge and patient information. This, in essence, is a communication failure, whether with the patient or other providers. [10]

- Failure to employ indicated tests is another medical error that can lead to diagnostic delays or errors. [1]

- Similarly, using outdated tests or treatments or failing to respond to the results of tests or monitoring also constitutes a type of medical error. [1]

- Treatment errors include errors during the performance of a test or procedure and inappropriate treatment. [1]

When applying root cause analysis for medical error prevention, it is essential to consider several patient-related factors and underlying issues that may hinder or impede the ability to generate an efficacious root cause analysis. Awareness of particular safety hazards for specific patient demographics and groups can often help mitigate common medical errors and encourage patients to take responsibility for their safety.

Elderly patients represent such a group as various common medical illnesses may result from age-related changes within this group. Elderly patients tend to be prone to falls due to their age-related changes in vision or cardiovascular problems. This patient group also tends to be prone to balance issues and muscle weakness over time, leading to ambulatory dysfunction. Having fall-prevention protocols in place, identifying potential high-risk areas within the home, and mitigating them through safety measures can improve patient safety and outcomes. [7] Age-associated hearing and cognitive decline increase the likelihood of communication errors regarding medications. Ensuring appropriate communication skills tailored to distinct patient groups is key to preventing such errors. Young children and infants are similarly prone to common medical errors due to the lack of direct participation in decision-making and patient care. Thus, specialized communication is needed to convey medical instructions to this population. It is essential to involve both the family and the child to ensure no lapses in communication.

Reducing diagnostic errors requires a more comprehensive approach. Common conditions misdiagnosed yearly include cancer, coronary artery disease, and surgical complications. [12] [13] Clinicians within these specialties must be aware of the high rate of misdiagnoses and attempt to combat this through additional measures. Many of these misdiagnoses are easily preventable by implementing standardized protocols, which can be integrated into electronic medical record software. [14] According to a 2015 New England Journal of Medicine article, "trigger tools" are essential in reducing this type of medical error. [15] "Trigger tools" are electronic algorithms that identify potential adverse events. This is accomplished by searching electronic health records and flagging specific occurrences. The use of trigger tools has been shown to decrease the rate of misdiagnoses in recent studies. [15]

Another important realization clinicians should be aware of is using an interpreter to aid in effective communication. A skilled medical interpreter may be crucial in effectively communicating instructions and information to the patient. Physicians need to utilize an unbiased and neutral medical interpreter, as family members may often be biased in communication.

Communication deficits among medical staff members are another essential root cause of medical errors that can be mitigated through standardized protocols. [16] The healthcare institution must recognize all staff members' inclusion in communication protocol development and identify processes for clinicians and pharmacists to exchange information regarding medication orders. Training staff to participate in error recognition and medication safety training is another valuable tool that can be implemented within a healthcare institution. Controlling the storage, access, and labeling of medications is another strategy that can be implemented and monitored to prevent errors that can be easily mitigated by storing medications in the accepted manner or by identifying protocols to ensure that similar medications are properly labeled to avoid mismatching. Managing the availability of information within the healthcare organization is also important. Ensuring staff members can readily access important updates and protocol changes can help prevent unnecessary medical errors.

- Clinical Significance

RCA has important implications in helping healthcare organizations study events that resulted in patient harm or undesired clinical outcomes and identify strategies to reduce future errors and improve patient care and safety. Most notably, RCA can help identify medication errors such as illegible handwritten prescriptions, similar name packaging or misleading drug strength or dosage presentations, ineffective control of prescription labels, and lapsed concentration due to interruptions. [17] Clinician participation in root cause analysis is vital as these initiatives recognize and address important patient care aspects.

Through a review of data gathered by the Joint Commission, six common categories of clinical error resulting in patient death, which can be prevented through root cause analysis, have been identified. These sentinel events account for a significant proportion of morbidity and mortality within the hospital setting. The six most common categories of clinical errors resulting in patient deaths include: [7]

- Wrong-site surgeries

- Patient suicide

- Surgical complications

- Medical treatment delays

- Medication errors

- Patient falls.

Wrong-site surgery is a major cause of medical errors that can be mitigated through various safety checkpoints preoperatively and has been the subject of a sentinel event alert by the Joint Commission. [7] [18] This type of error has most commonly been noted in orthopedic surgeries. [19] Risk factors include several surgeons involved in surgical care or transfers to another surgeon for patient care, multiple procedures on a single patient, time constraint pressures, and unique circumstances requiring unusual or special positioning during a surgical procedure. [18] This error can easily be mitigated by ensuring proper pre-operative measures, such as labeling the correct surgical site with an indelible pen or distinctively marking the nonsurgical site before the surgery. Intraoperative radiography can also assist in aiding the correct surgical site during the procedure.

Patient suicide is an unfortunate cause of death commonly seen in psychiatric care settings. [7] Several risk-reduction methods can be implemented for this adverse event, including ensuring a controlled environment free of hazardous materials, frequent patient observation, effective communication, adequate staffing in the facility, suicide assessment upon admission, regular psychiatric evaluation, and assessment for the presence of contraband.

Delays in medical treatment are preventable adverse events that may result in patient death and permanent injuries. This may result from misdiagnoses, delayed diagnostic test results, lack of staffing or physician availability, delays in order fulfillment, inadequate treatment, and delays within the emergency department. It is important to recognize this root cause and implement steps to improve timeliness, completeness and check the accuracy of medical communication to prevent such errors.

Medication administration errors are a common and avoidable adverse event that can occur at various patient care levels, involving many individuals in a multidisciplinary patient care team. [17] The primary tool of prevention for this type of error is communication. A standardized protocol for communication between the physician, nurse, pharmacist, and other clinicians involved in patient care is essential to ensure that patients receive the correct medication at the appropriate dosage, route, and frequency.

Similarly, patient falls are a constant source of error within healthcare facilities. It is important to recognize patients at high risk for falls and take appropriate safety precautions. Standardized protocols can reduce fall rates by ensuring a safe environment for risk-prone patients. Patient factors contributing to falls include advanced age, mobility impairment, and surgery. [20] Organizational factors contributing to falls include nurse staffing and the proportion of new nurses. [20] Instuting fall prevention protocols in hospitals and long-term care facilities have significantly impacted reducing these errors. Studies have shown that fall risk assessments using standardized scales such as the Morse Fall Scale can decrease patient falls. [21] Institutional interventions such as staff education, patient mobility training with rehabilitation professionals, and nutritionist support have also been shown to reduce patient falls. [21]

- Enhancing Healthcare Team Outcomes

Medical errors are undeniably an important cause of patient morbidity and mortality within the United States healthcare system. These errors are prevalent at rampant levels, and the consequences of such errors can have severe impacts on the patient, family members, and clinicians. The interprofessional healthcare team plays an invaluable role in preventing medical errors; team effort is crucial in identifying strategies and solutions to reduce the burden of medical error on the healthcare system. Nurses, pharmacists, rehabilitation professionals, nutritionists, and physicians are integral to the patient care team and crucial in preventing medical errors. Practitioners who work in error-prone environments must recognize their roles as healthcare team members who are responsible for reducing unnecessary errors. [22] The interprofessional team members comprising the RCA team should include professionals from all disciplines to ensure an effective and accurate RCA occurs.[Level 5]

Clinicians should not hesitate to provide their peers with assistance in recognizing particular sources of common medical errors to deliver better patient care. Equal accountability and responsibility of all healthcare team members are critical in preventing errors and providing superior patient safety. [1]

Quality assurance teams should employ RCAs with every sentinal event, especially in situations when the identification of medical errors becomes difficult or complex due to many underlying factors. RCAs can help identify factors within the healthcare delivery process that may impede the ability to provide quality patient care. Given the preventable nature of most medical errors, a thorough RCA can improve patient safety and allow healthcare organizations to serve as a model for others.

Healthcare professionals should be aware of common medical error sources and work as a team to identify possible risks when they become apparent. Doing so will increase the quality and efficiency of the healthcare industry and patient trust in the healthcare system. When an RCA is performed, the cooperation of all healthcare team members and clinicians involved in patient care is critical to understanding the "Why" behind the source of medical error and identifying future strategies to mitigate such errors and improve patient outcomes.[Level 5]

- Review Questions

- Access free multiple choice questions on this topic.

- Comment on this article.

Disclosure: Gunjan Singh declares no relevant financial relationships with ineligible companies.

Disclosure: Raj Patel declares no relevant financial relationships with ineligible companies.

Disclosure: Joshua Boster declares no relevant financial relationships with ineligible companies.

This book is distributed under the terms of the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC BY-NC-ND 4.0) ( http://creativecommons.org/licenses/by-nc-nd/4.0/ ), which permits others to distribute the work, provided that the article is not altered or used commercially. You are not required to obtain permission to distribute this article, provided that you credit the author and journal.

- Cite this Page Singh G, Patel RH, Boster J. Root Cause Analysis and Medical Error Prevention. [Updated 2023 May 30]. In: StatPearls [Internet]. Treasure Island (FL): StatPearls Publishing; 2024 Jan-.

In this Page

Bulk download.

- Bulk download StatPearls data from FTP

Related information

- PMC PubMed Central citations

- PubMed Links to PubMed

Similar articles in PubMed

- Medical Error Reduction and Prevention. [StatPearls. 2024] Medical Error Reduction and Prevention. Rodziewicz TL, Houseman B, Hipskind JE. StatPearls. 2024 Jan

- Prevention of Surgical Errors. [StatPearls. 2024] Prevention of Surgical Errors. Santos G, Jones MW. StatPearls. 2024 Jan

- Pilot Medical Certification. [StatPearls. 2024] Pilot Medical Certification. Matthews MJ, Stretanski MF. StatPearls. 2024 Jan

- Review Tuberculosis. [Major Infectious Diseases. 2017] Review Tuberculosis. Bloom BR, Atun R, Cohen T, Dye C, Fraser H, Gomez GB, Knight G, Murray M, Nardell E, Rubin E, et al. Major Infectious Diseases. 2017 Nov 3

- Review Suffering in Silence: Medical Error and its Impact on Health Care Providers. [J Emerg Med. 2018] Review Suffering in Silence: Medical Error and its Impact on Health Care Providers. Robertson JJ, Long B. J Emerg Med. 2018 Apr; 54(4):402-409. Epub 2018 Feb 1.

Recent Activity

- Root Cause Analysis and Medical Error Prevention - StatPearls Root Cause Analysis and Medical Error Prevention - StatPearls

Your browsing activity is empty.

Activity recording is turned off.

Turn recording back on

Connect with NLM

National Library of Medicine 8600 Rockville Pike Bethesda, MD 20894

Web Policies FOIA HHS Vulnerability Disclosure

Help Accessibility Careers

- Aerospace Overview

- Light Aircraft

- Construction

- Entertainment

- Financial Institutions

- Food and Agriculture

- Higher Education

- Life Sciences

- Manufacturing

- Nonprofit Overview

- Affordable Housing Insurance and Consulting for Nonprofits

- Human Services Consulting

- Showguard™ Event Insurance

- PEO and Temporary Staffing

- Private Equity and M&A

- Public Sector & K-12 Education

- Real Estate and Hospitality

- Restaurants

- Senior Living

- Transportation

- Alternative Risk & Captives

- Business Continuity Planning and Resiliency Services

- Claims Overview

- Commercial Lines Claims Contacts

- Small Business Lines Claims Contacts

- Home and Property Lines Claims Contacts

- Claims Management & Advocacy

- Claims Management and Third Party Administration

- Commercial Surety Bonds

- Construction Bonds

- Credit and Political Risk

- Crisis Resilience Insurance & Consulting

- Data and Analytics

- Enterprise Risk Management

- Environmental

- Executive and Financial Risk

- Global Risk Management

- Loss Control

- Multinational Services Overview

- Asia Pacific

- Personal Lines

- Product Recall

- Reinsurance

- Small Business

- Supplier Diversity

- Workers Compensation

- Insurance and Risk Management Webinars

- Compensation Consulting and Total Rewards Programs

- Compensation Survey Reports

- Compliance Consulting Overview

- Healthcare Reform Toolkit

- Diversity, Equity and Inclusion (DEI) Consulting

- Employee Communications Consulting

- Engagement Solutions

- ESG Consulting

- Executive Benefits

- Executive Compensation Consulting

- Executive Search Overview

- Executive Career Opportunities

- Health and Welfare Consulting

- Healthcare Analytics Consulting

- Human Resources and Compensation Consulting Overview

- Meet the Human Resource Compensation Consulting Team

- Human Resources Consulting

- Human Resources Technology Consulting

- Individual Life and Wealth Consulting

- Investment and Fiduciary Consulting

- Leadership Advisors

- Multinational Benefits and HR Consulting

- Pharmacy Benefit Management Consulting

- Physical and Emotional Wellbeing Consulting

- Physician Compensation and Valuation

- Research and Insights

- Retirement Plan Consulting

- Voluntary Benefits Consulting

- News & Insights

- Investor Relations

- Our Purpose

- Executive Team

- The Gallagher Way

- Gallagher Companies

- Recognition & Awards

- How We Work Overview

- Mission Statement

- Gallagher Better Works

- Tools and Applications

- Merge with Gallagher

- Gallagher Global Network

- Office Locations

- Partnerships

- Inclusion and Diversity

- Global Standards

- Compensation Disclosure

Root Cause Analysis in Higher Education

Author: John Watson