- A Step-by-Step Guide to A3 Problem Solving Methodology

- Learn Lean Sigma

- Problem Solving

Problem-solving is an important component of any business or organization. It entails identifying, analyzing, and resolving problems in order to improve processes, drive results, and foster a culture of continuous improvement. A3 Problem solving is one of the most effective problem-solving methodologies.

A3 Problem solving is a structured and systematic approach to problem-solving that originated with the lean manufacturing methodology. It visualizes the problem-solving process using a one-page document known as an A3 report. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner.

A3 Problem Solving has numerous advantages, including improved communication, better decision-making, increased efficiency, and reduced waste. It is a powerful tool for businesses of all sizes and industries, and it is especially useful for solving complex and multi-faceted problems.

In this blog post, we will walk you through the A3 Problem Solving methodology step by step. Whether you are new to A3 Problem Solving or simply want to improve your skills, this guide will help you understand and apply the process in your workplace.

Table of Contents

What is a3 problem solving.

A3 Problem Solving is a structured and systematic approach to problem-solving that makes use of a one-page document called an A3 report to visually represent the process. The A3 report provides an overview of the problem, data analysis, root causes, solutions, and results in a clear and concise manner. The method was created within the framework of the Lean manufacturing methodology and is based on the principles of continuous improvement and visual management.

Looking for a A3 Problem solving template? Click here

Origin and History of A3 Problem Solving

A3 Problem Solving was developed by Toyota Motor Corporation and was first used in the manufacture of automobiles. The term “A3” refers to the size of the paper used to create the report, which is an ISO standard known as “A3”. The goal of the A3 report is to provide a visual representation of the problem-solving process that all members of the organisation can easily understand and share. A3 Problem Solving has been adopted by organisations in a variety of industries over the years, and it has become a widely used and recognised method for problem-solving.

Key Principles of A3 Problem Solving

The following are the key principles of A3 Problem Solving:

- Define the problem clearly and concisely

- Gather and analyze data to gain a deep understanding of the problem

- Identify the root causes of the problem

- Develop and implement effective solutions

- Evaluate results and continuously improve

These principles serve as the foundation of the A3 Problem Solving methodology and are intended to assist organisations in continuously improving and achieving their objectives. Organizations can effectively solve problems, identify areas for improvement, and drive results by adhering to these principles.

Step 1: Define the Problem

Importance of clearly defining the problem.

The first step in the A3 Problem Solving process is critical because it lays the groundwork for the remaining steps. To define the problem clearly and accurately, you must first understand the problem and identify the underlying root cause. This step is critical because if the problem is not correctly defined, the rest of the process will be based on incorrect information, and the solution developed may not address the issue effectively.

The significance of defining the problem clearly cannot be overstated. It aids in the collection and analysis of relevant data, which is critical for developing effective solutions. When the problem is clearly defined, the data gathered is more relevant and targeted, resulting in a more comprehensive understanding of the issue. This will enable the development of solutions that are more likely to be effective because they are founded on a thorough and accurate understanding of the problem.

However, if the problem is not clearly defined, the data gathered may be irrelevant or incorrect, resulting in incorrect conclusions and ineffective solutions. Furthermore, the process of collecting and analysing data can become time-consuming and inefficient, resulting in resource waste. Furthermore, if the problem is not accurately defined, the solutions developed may fail to address the root cause of the problem, resulting in ongoing issues and a lack of improvement.

Techniques for Defining the Problem

The first step in the A3 Problem Solving process is to clearly and accurately define the problem. This is an important step because a clearly defined problem will help to ensure that the appropriate data is collected and solutions are developed. If the problem is not clearly defined, incorrect data may be collected, solutions that do not address the root cause of the problem, and time and resources may be wasted.

A problem can be defined using a variety of techniques, including brainstorming , root cause analysis , process mapping , and Ishikawa diagrams . Each of these techniques has its own advantages and disadvantages and can be used in a variety of situations depending on the nature of the problem.

Best Practice for Defining the Problem

In addition to brainstorming, root cause analysis, process mapping, and Ishikawa diagram s, best practices should be followed when defining a problem in A3 Problem Solving. Among these best practices are:

- Define the issue in a specific and quantifiable way: It is critical to be specific and concise when defining the problem, as well as to quantify the problem in terms of its impact. This will help to ensure that all stakeholders understand the problem and that data collection is focused on the right areas.

- Focus on the problem’s root cause: The A3 Problem Solving methodology is intended to assist organisations in identifying and addressing the root cause of a problem, rather than just the symptoms. Organizations can ensure that their solutions are effective and long-lasting by focusing on the root cause of the problem.

- Ascertain that all stakeholders agree on the problem’s definition: All stakeholders must agree on the definition of the problem for the A3 Problem Solving process to be effective. This ensures that everyone is working towards the same goal and that the solutions developed are relevant and appropriate.

- Consider the problem’s impact on the organisation and its stakeholders: It is critical to consider the impact of the problem on the organisation and its stakeholders when defining it. This will assist in ensuring that the appropriate data is gathered and that the solutions developed are relevant and appropriate.

Organizations can ensure that their problem is defined in a way that allows for effective data collection, analysis, and solution development by following these best practices. This will aid in the development of appropriate solutions and the effective resolution of the problem, resulting in improvements in the organization’s processes and outcomes.

Step 2: Gather Data

Gathering data in a3 problem solving.

Data collection is an important step in the A3 Problem Solving process because it allows organisations to gain a thorough understanding of the problem they are attempting to solve. This step entails gathering pertinent information about the problem, such as data on its origin, impact, and any related factors. This information is then used to help identify root causes and develop effective solutions.

One of the most important advantages of data collection in A3 Problem Solving is that it allows organisations to identify patterns and trends in data, which can be useful in determining the root cause of the problem. This information can then be used to create effective solutions that address the problem’s root cause rather than just its symptoms.

In A3 Problem Solving, data collection is a collaborative effort involving all stakeholders, including those directly impacted by the problem and those with relevant expertise or experience. Stakeholders can ensure that all relevant information is collected and that the data is accurate and complete by working together.

Overall, data collection is an important step in the A3 Problem Solving process because it serves as the foundation for effective problem-solving. Organizations can gain a deep understanding of the problem they are attempting to solve and develop effective solutions that address its root cause by collecting and analysing relevant data.

Data Collection Methods

In A3 Problem Solving, several data collection methods are available, including:

- Observations

- Process diagrams

The best data collection method will be determined by the problem being solved and the type of data required. To gain a complete understanding of the problem, it is critical to use multiple data collection methods.

Tools for Data Analysis and Visualization

Once the data has been collected, it must be analysed and visualised in order to gain insights into the problem. This process can be aided by the following tools:

- Excel Spreadsheets

- Flow diagrams

- Pareto diagrams

- Scatter Plots

- Control diagrams

These tools can assist in organising data and making it easier to understand. They can also be used to generate visual representations of data, such as graphs and charts, to communicate the findings to others.

Finally, the data collection and analysis step is an important part of the A3 Problem Solving process. Organizations can gain a better understanding of the problem and develop effective solutions by collecting and analysing relevant data.

Step 3: Identify Root Causes

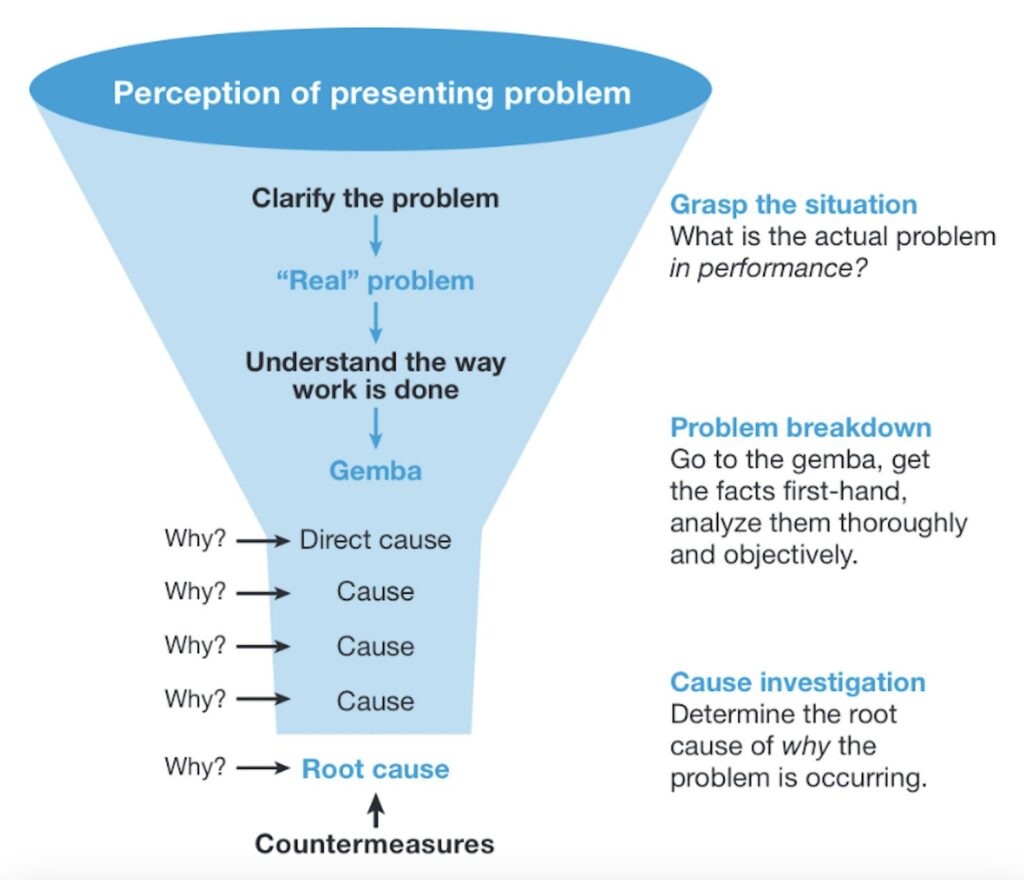

Identifying the root causes of the problem is the third step in the A3 Problem Solving process. This step is critical because it assists organisations in understanding the root causes of a problem rather than just its symptoms. Once the underlying cause of the problem is identified, it can be addressed more effectively, leading to more long-term solutions.

Overview of the Root Cause Analysis Process

The process of determining the underlying causes of a problem is known as root cause analysis. This process can assist organisations in determining why a problem is occurring and what can be done to prevent it from recurring in the future. The goal of root cause analysis is to identify the underlying cause of a problem rather than just its symptoms, allowing it to be addressed more effectively.

To understand Root cause analysis in more detail check out RCA in our Lean Six Sigma Yellow Belt Course Root Cause Analysis section

Techniques for Identifying Root Causes

There are several techniques for determining the root causes of a problem, including:

- Brainstorming

- Ishikawa diagrams (also known as fishbone diagrams)

- Root Cause Tree Analysis

These methods can be used to investigate the issue in-depth and identify potential root causes. Organizations can gain a deeper understanding of the problem and identify the underlying causes that must be addressed by using these techniques.

Best Practices for Conducting Root Cause Analysis

It is critical to follow these best practices when conducting root cause analysis in A3 Problem Solving:

- Make certain that all stakeholders participate in the root cause analysis process.

- Concentrate on determining the root cause of the problem rather than just its symptoms.

- Take into account all potential root causes, not just the most obvious ones.

- To identify root causes, use a systematic approach, such as the 5 Whys or root cause tree analysis.

Organizations can ensure that root cause analysis is carried out effectively and that the root cause of the problem is identified by adhering to these best practises. This will aid in the development of appropriate solutions and the effective resolution of the problem.

Step 4: Develop Solutions

Developing solutions is the fourth step in the A3 Problem Solving process. This entails generating ideas and options for dealing with the problem, followed by selecting the best solution. The goal is to develop a solution that addresses the root cause of the problem and prevents it from recurring.

Solution Development in A3 Problem Solving

A3 solution development Problem solving is an iterative process in which options are generated and evaluated. The data gathered in the previous steps, as well as the insights and understanding gained from the root cause analysis, guide this process. The solution should be based on a thorough understanding of the problem and address the underlying cause.

Techniques for Developing Solutions

There are several techniques that can be used to develop solutions in A3 Problem Solving, including:

- Brainwriting

- Solution matrix

- Multi voting

- Force field analysis

These techniques can help to generate a range of options and to select the best solution.

Best Practice for Developing Solutions

It is critical to follow the following best practices when developing solutions in A3 Problem Solving:

- Participate in the solution development process with all stakeholders.

- Make certain that the solution addresses the underlying cause of the problem.

- Make certain that the solution is feasible and achievable.

- Consider the solution’s impact on the organisation and its stakeholders.

Organizations can ensure that the solutions they develop are effective and sustainable by adhering to these best practises. This will help to ensure that the problem is addressed effectively and that it does not reoccur.

Step 5: Implement Solutions

The final and most important step in the A3 Problem Solving methodology is solution implementation. This is the stage at which the identified and developed solutions are put into action to address the problem. This step’s goal is to ensure that the solutions are effective, efficient, and long-lasting.

The implementation Process

The implementation process entails putting the solutions developed in the previous step into action. This could include changes to processes, procedures, and systems, as well as employee training and education. To ensure that the solutions are effective, the implementation process should be well-planned and meticulously executed.

Techniques for Implementing Solutions

A3 Problem Solving solutions can be implemented using a variety of techniques, including:

- Piloting the solution on a small scale before broadening its application

- Participating in the implementation process with all relevant stakeholders

- ensuring that the solution is in line with the goals and objectives of the organisation

- Monitoring the solution to determine its effectiveness and make any necessary changes

Best Practice for Implementing Solutions

It is critical to follow these best practices when implementing solutions in A3 Problem Solving:

Make certain that all relevant stakeholders are involved and supportive of the solution. Have a clear implementation plan that outlines the steps, timeline, and resources required. Continuously monitor and evaluate the solution to determine its efficacy and make any necessary changes. Encourage all stakeholders to communicate and collaborate openly. Organizations can ensure that solutions are effectively implemented and problems are effectively addressed by adhering to these best practices. The ultimate goal is to find a long-term solution to the problem and improve the organization’s overall performance.

In conclusion, A3 Problem Solving is a comprehensive and structured methodology for problem-solving that can be applied in various industries and organisations. The A3 Problem Solving process’s five steps – Define the Problem, Gather Data, Identify Root Causes, Develop Solutions, and Implement Solutions – provide a road map for effectively addressing problems and making long-term improvements.

Organizations can improve their problem-solving skills and achieve better results by following the key principles, techniques, and best practices outlined in this guide. As a result, both the organisation and its stakeholders will benefit from increased efficiency, effectiveness, and satisfaction. So, whether you’re an experienced problem solver or just getting started, consider incorporating the A3 Problem Solving methodology into your work and start reaping the benefits right away.

Daniel Croft

Daniel Croft is a seasoned continuous improvement manager with a Black Belt in Lean Six Sigma. With over 10 years of real-world application experience across diverse sectors, Daniel has a passion for optimizing processes and fostering a culture of efficiency. He's not just a practitioner but also an avid learner, constantly seeking to expand his knowledge. Outside of his professional life, Daniel has a keen Investing, statistics and knowledge-sharing, which led him to create the website learnleansigma.com, a platform dedicated to Lean Six Sigma and process improvement insights.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

5S Floor Marking Best Practices

In lean manufacturing, the 5S System is a foundational tool, involving the steps: Sort, Set…

How to Measure the ROI of Continuous Improvement Initiatives

When it comes to business, knowing the value you’re getting for your money is crucial,…

8D Problem-Solving: Common Mistakes to Avoid

In today’s competitive business landscape, effective problem-solving is the cornerstone of organizational success. The 8D…

The Evolution of 8D Problem-Solving: From Basics to Excellence

In a world where efficiency and effectiveness are more than just buzzwords, the need for…

8D: Tools and Techniques

Are you grappling with recurring problems in your organization and searching for a structured way…

How to Select the Right Lean Six Sigma Projects: A Comprehensive Guide

Going on a Lean Six Sigma journey is an invigorating experience filled with opportunities for…

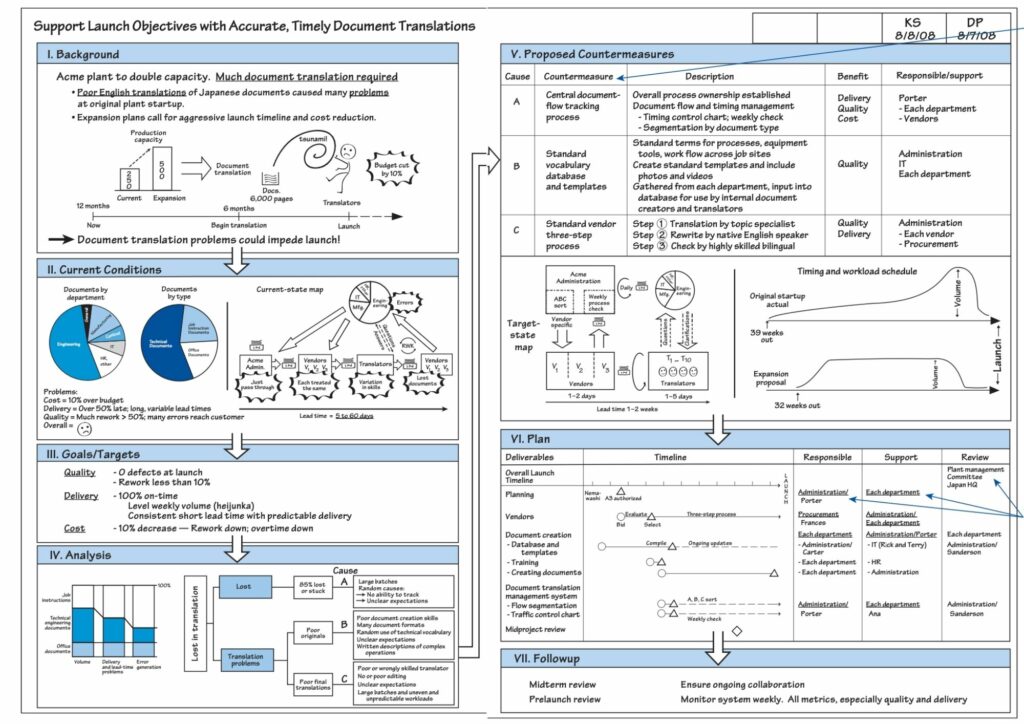

An A3 Report is a Toyota-pioneered practice of getting the problem, the analysis, the corrective actions, and the action plan down on a single sheet of large (A3) paper, often with the use of graphics. At Toyota, A3 reports have evolved into a standard method for summarizing problem-solving exercises, status reports, and planning exercises like value-stream mapping.

But it is much more than a sheet a paper with facts and figures. It is a management process learned through dialogue about concrete problems. It does this by means of a dialogue between a lean manager and a subordinate who learns lean management and leadership as she solves an important problem.

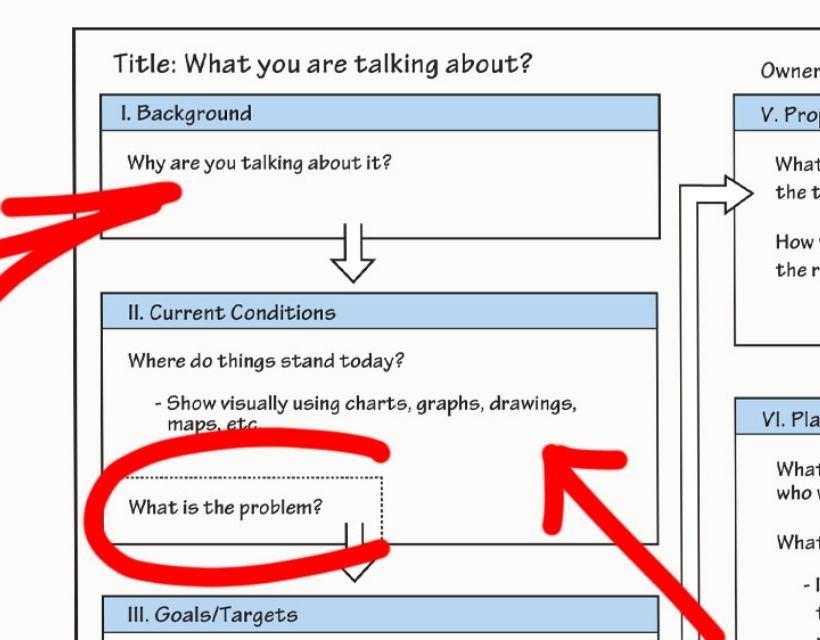

This process of solving problems while creating better employees—A3 analysis—is core to the Toyota management system. An A3 report guides the dialogue and analysis. It identifies the current situation, the nature of the issue, the range of possible counter- measures, the best countermeasure, the means (who will do what when) to put it into practice, and the evidence that the issue has actually been addressed.

The lean leader’s job is to develop people. If the worker hasn’t learned, the teacher hasn’t taught. Training Within Industry Report (Washington, DC: War Manpower Commission, Bureau of Training, 1945).

Effective use of the A3 process can facilitate the shift from a debate about who owns what (an authority-focused debate) to a dialogue around what is the right thing to do (a responsibility-focused conversation). This shift has a radical impact on the way decisions are made. Individuals earn the authority to take action through the manner in which they frame the issue. They form consensus and get decisions made by focusing relentlessly on indisputable facts that they and their peers derive from the gemba.

As a result, A3 management can best be understood as neither “top-down” nor “bottom-up.” The process clarifies responsibility by placing ownership squarely on the shoulders of the author-owner of the A3, the individual whose initials appear in the upper right-hand corner of the paper. This person may not have direct authority over every aspect of the proposal. Yet this owner is clearly identified as the person who has taken or accepted responsibility to get decisions made and implemented .

Example A3s

The Many Facets of A3

- A standard paper size: At its most fundamental, “A3” is the international term for a sheet of paper 297 millimeters wide and 420 millimeters long. The closest U.S. paper size is the 11-by-17-inch tabloid sheet.

- A template: Many companies and individuals use an A3-sized document pre-printed with the steps needed to conduct lean problem-solving or improvement efforts, with generous white space for “A3 owners” to record their progress. While they refer to this document as a template, an “A3” is not a template.

- A storyboard: As users record their problem-solving or improvement project’s progress, the A3 becomes a storyboard used to facilitate communication, collaboration, and coordination with other stakeholders affected by the goal the A3 owner is working toward (e.g., solving a problem or improving a process ). By having all the facts about the effort in one place, logically presented and summarized, the A3 owner is better able to gain buy-in from other stakeholders for recommended process changes.

- A report: Once the A3 problem-solving effort concludes, the A3 storyboard serves as a report of the problem-solving or improvement initiative, including the facts and data gathered, hypotheses considered, countermeasures tried, experiment results, corrective actions taken, and the overall thinking of the A3 owner and stakeholders. At Toyota and elsewhere, A3 reports have evolved into a standard method for summarizing problem-solving exercises, status reports, and planning exercises like value-stream mapping.

- A problem-solving methodology (or process): Most lean practitioners know “the A3” as a problem-solving process guided by specific steps or questions. The left side of the A3 focuses on various elements of the problem or current condition, and the right on the countermeasures considered, tested, and chosen that resolves the issue or creates a higher standard.

- A management discipline (or process): At a higher level, lean leaders, managers, and supervisors use “the A3” as a means by which they oversee and guide subordinates while simultaneously helping them develop their lean thinking and practice — particularly lean leadership and problem-solving — capabilities. With A3 management, leaders challenge their direct reports to solve a problem. Then, with the A3 report guiding the dialogue and analysis, leaders coach them through the problem-solving process. Importantly, leaders coach by asking questions versus providing answers, ensuring responsibility remains with the subordinate to solve the problem by pursuing facts and building consensus. Through this interaction, subordinates address the issue, allowing them to make progress toward the objective and, in so doing, learn the lean approach to leadership and management and gain problem-solving capability.

- A3 thinking (or analysis): Most A3 coaches and advanced lean practitioners refer to “the A3” as a thinking process. In this case, the term refers to a systematic approach to resolving problems or improving work processes. Someone can follow this systematic approach, regardless of whether they are guided by or record their findings on an A3 document.

- An alignment tool: Advanced lean organizations that have incorporated lean thinking and practices throughout their operations use “A3s” as part of their strategy deployment and execution efforts. In this case, the A3 process ensures a standard approach to managing and coaching people, all directed toward solving problems that help achieve corporate objectives.

Additional Resources

How Do I Start My A3?

When asked “where do I start to write my A3,” David Verble responds “don’t start by writing.” His piece, the first in a series about getting started, offers lessons he has learned about the nature of thinking, and a productive way to start the A3 by recognzing it as a thinking process.

Don’t Present Your A3: Share Your A3

When asked “where do I start to write my A3,” David Verble responds “don’t start by writing.” His piece, the first in a series about getting started, offers lessons he has learned about the nature of thinking, and a productive way to start by recognizing it as a thinking process.

Related Books

Related Online Courses

Intro to Problem Solving

Problem-solving is critical to every position in every industry. In this course, you will learn to grasp the situation at the gemba (where the work is done) and use all of your senses to understand what is truly happening.

See: Value Stream Mapping

Privacy Overview

IMAGES

VIDEO