- Bibliography

- More Referencing guides Blog Automated transliteration Relevant bibliographies by topics

- Automated transliteration

- Relevant bibliographies by topics

- Referencing guides

Municipal solid waste management in Russia: potentials of climate change mitigation

- Original Paper

- Open access

- Published: 29 July 2021

- Volume 19 , pages 27–42, ( 2022 )

Cite this article

You have full access to this open access article

- C. Wünsch ORCID: orcid.org/0000-0002-3839-6982 1 , 2 &

- A. Tsybina 3

4713 Accesses

4 Citations

23 Altmetric

Explore all metrics

The goal of this study was to assess the impact of the introduction of various waste management methods on the amount of greenhouse gas emissions from these activities. The assessment was carried out on the example of the Russian waste management sector. For this purpose, three scenarios had been elaborated for the development of the Russian waste management sector: Basic scenario, Reactive scenario and Innovative scenario. For each of the scenarios, the amount of greenhouse gas emissions generated during waste management was calculated. The calculation was based on the 2006 Intergovernmental Panel on Climate Change Guidelines for National Greenhouse Gas Inventories. The results of the greenhouse gas net emissions calculation are as follows: 64 Mt CO 2 -eq./a for the basic scenario, 12.8 Mt CO 2 -eq./a for the reactive scenario, and 3.7 Mt CO 2 -eq./a for the innovative scenario. An assessment was made of the impact of the introduction of various waste treatment technologies on the amounts of greenhouse gas emissions generated in the waste management sector. An important factor influencing the reduction in greenhouse gas emissions from landfills is the recovery and thermal utilization of 60% of the generated landfill gas. The introduction of a separate collection system that allows to separately collect 20% of the total amount of generated municipal solid waste along with twofold increase in the share of incinerated waste leads to a more than threefold reduction in total greenhouse gas emissions from the waste management sector.

Similar content being viewed by others

Greenhouse gas emissions and cost assessments of municipal solid waste treatment and final disposal in maputo city.

Toward sustainable waste management: estimating emissions from alternative practices in Gulf Cooperation Council countries

The analysis of electricity production and greenhouse-gas emission reduction from municipal solid waste sector in Oman

Avoid common mistakes on your manuscript.

Introduction

Population growth, urbanization and changing life style have resulted in increased amounts of generated solid waste, which poses serious challenges for many cities and authorities around the world (Abu Qdais et al. 2019 ; Chen 2018 ; Dedinec et al. 2015 ). In 2011, world cities generated about 1.3 Gt of solid waste; this amount is expected to increase to 2.2 Gt by 2025 (Hoornweg and Bhada-Tata 2012 ). Unless properly managed on a national level, solid waste causes several environmental and public health problems, which is adversely reflected on the economic development of a country (Abu Qdais 2007 ; Kaza et al. 2018 ).

One of the important environmental impact of the waste management sector are the generated greenhouse gas (GHG) emissions. These emissions come mostly from the release of methane from organic waste decomposition in landfills (Wuensch and Kocina 2019 ). The waste management sector is responsible for 1.6 Gt carbon dioxide equivalents (CO 2 -eq.) of the global GHG direct anthropogenic emissions per year (Fischedick et al. 2014 ), which accounts for approx. 4% of the global GHG emissions (Papageorgiou et al. 2009 ; Vergara and Tchobanoglous 2012 ). The disposal of municipal solid waste (MSW) contributes to 0.67 Gt CO 2 -eq./a worldwide (Fischedick et al. 2014 ), which is approx. 1.4% of the global GHG emissions. Per capita emissions in developed countries are estimated to be about 500 kg CO 2 -eq./a (Wuensch and Kocina 2019 ), while in the developing and emerging countries, it is around 100 kg CO 2 -eq./a per person. This low contribution of waste management sector comparing to other sectors of the economy, such as energy and transportation, might be the reason for the small amount of research that aims to study GHG emissions from the waste management sector (Chung et al. 2018 ).

However, it is important to consider that the mitigation of GHG emissions from waste management sector is relatively simple and cost-effective as compared to other sectors of the economy. Several studies proved that separate waste collection and composting of biowaste as well as landfilling with landfill gas recovery is currently found to be one of the most effective and economically sound GHG emissions mitigation options (Chen 2018 ; EI-Fadel and Sbayti 2000 ; Yedla and Sindhu 2016 ; Yılmaz and Abdulvahitoğlu 2019 ). Metz et al. 2001 estimated that 75% of the savings of methane recovered from landfills can be achieved at net negative direct cost, and 25% at cost of about 20 US$/Mg CO 2 -eq./a. In any country of the world, the potential of the waste management sector is not yet fully utilized; the implementation of relatively simple and inexpensive waste treatment technologies might contribute to national GHG mitigation goals and convert the sector from a net emitter into a net reducer of GHG emissions (Crawford et al. 2009 ; Voigt et al. 2015 ; Wuensch and Simon 2017 ).

While there are many well-established solutions and technologies for the reduction in GHG emitted from the waste sector, there is no universal set of options that suits all the countries. When thinking to adapt certain solutions of GHG mitigation, it is important to take into account local circumstances such as waste quantities and composition, available infrastructure, economic resources and climate (Crawford et al. 2009 ).

It is expedient to assess how the introduction of modern waste management methods affects the amount of GHG emissions from the waste management process by the example of those countries in which the waste management sector is undergoing reform. These countries include the Russian Federation, where the values of targets for the waste management industry until 2030 are legally established (Government of the Russian Federation 2018 ). In addition, on February 8, 2021, Russia issued a Presidential Decree “On Measures to Implement State Scientific and Technical Policy in the Field of Ecology and Climate,” which prescribes the creation of a Federal Program for the Creation and Implementation of Science-Intensive Technologies to Reduce Greenhouse Gas Emissions (Decree of the President of the Russian Federation 2021 ).

The goal of this study was to quantify the impact of the introduction of various modern waste treatment methods on the volume of GHG emissions from the waste management sector using the example of Russia. To achieve this goal, the following objectives were set and solved:

Elaborate scenarios for the development of the waste management industry, based on the established Industry Development Strategy for the period up to 2030 (Government of the Russian Federation 2018 )

Determine the weighted average morphological composition of MSW;

Select emission factors for various waste treatment methods;

Calculate GHG emissions under each scenario and analyze the calculation results.

The study was conducted from November 2019 to May 2020; the text was updated in March 2021 in connection with the changed situation, as climate change issues began to play an important role on the agenda in Russia. The study and its calculations are theoretical in nature and did not involve experimental research. It was carried out by the authors at their place of work—in Germany (Technische Universität Dresden, Merseburg University of Applied Sciences) and in Russia (Perm National Research Polytechnic University).

Greenhouse gas emissions related to municipal solid waste management sector in Russia

According to the State Report on the Status of Environmental Protection of the Russian Federation of 2018 (Ministry of Natural Resources and Ecology of the Russian Federation 2019 ), the volume of generated MSW has increased by 17% from 235.4 to 275.4 m 3 (49.9 to 58.4 Mt) during the time period 2010 to 2018. With approx. 147 million inhabitants, the annual per capita generation rate is about 400 kg. Until now, MSW management in Russia has been disposal driven. More than 90% of MSW generated is transported to landfills and open dump sites; 30% of the landfills do not meet sanitary requirements (Korobova et al. 2014 ; Tulokhonova and Ulanova 2013 ). According to the State Register of the Waste Disposal Facilities in Russia, there were 1,038 MSW landfills and 2,275 unregistered dump sites at the end of 2018 (Rosprirodnadzor 2019 ). Such waste management practices are neither safe nor sustainable (Fedotkina et al. 2019 ), as they pose high public health and environmental risks and lead to the loss of valuable recyclable materials such as paper, glass, metals and plastics which account for an annual amount of about 15 Mt (Korobova et al. 2014 ).

According to the United Nations Framework Convention on Climate Change (UNFCCC) requirements, the signatory parties of the convention need to prepare and submit national communication reports that document GHG emissions and sinks in each country by conducting an inventory based on Intergovernmental Panel on Climate Change (IPCC) guidelines (UNFCCC 2006 ). Being the fourth biggest global emitter of GHG emissions, Russia submitted its latest National Inventory Report (NIR) to UNFCCC in April 2019. The report documents national GHG emissions by source and removals by sink (Russian Federation 2019 ). The total emissions had been decreased from 3.2 Gt in 1990 to about 2.2 Gt of CO 2 -eq. in 2017, which implies 30% reduction over a period of 27 years. At the same time, the emissions from the disposal of solid waste increased from 33 Mt in 1990 by more than 100% to 69 Mt CO 2 -eq. in 2017. In terms of methane emissions, Russian solid waste disposal sector is the second largest emitter in the country and accounts for 18.1% of the total emitted methane mostly in the form of landfill gas, while the energy sector is responsible for 61.2% of methane emissions (Russian Federation 2019 ).

Landfill gas recovery from MSW landfills is not widely practiced in the Russian Federation. According to the statistics of the Russian Ministry of Natural Resources and Ecology, the share of landfill gas energy in the total renewable energy produced in Russia was 8.61%, 5.43%, 2.77% and 2.59% in 2011, 2012, 2013 and 2014, respectively (Arkharov et al. 2016 ). Different studies show that the potential of recovering energy from landfill gas in the Russian Federation is high (Arkharov et al. 2016 ; Sliusar and Armisheva 2013 ; Starostina et al. 2018 ; Volynkina et al. 2009 ).

Waste-to-energy technology is still in its infancy in Russia; the country is lagging in this area (Tugov 2013 ). Despite that, there is a great interest among the public as well as the private sector in the possibilities of the recovery of energy from MSW. In April 2014, the State Program “Energy Efficiency and Energy Development” was approved, which includes a subprogram on the development of renewable energy sources in the Russian Federation (Government of the Russian Federation 2014 ). In this program, MSW was considered as a source of renewable energy. Until the year 2017, there were only four waste incineration plants in Moscow region processing 655,000 Mg MSW per year, with only one incinerator recovering energy in form of heat and electricity (Dashieva 2017 ). In the nearest future, the construction of four additional incinerators in Moscow region and one in the city of Kazan is planned. The annual total combined capacity of the four new plants in Moscow will be about 2.8 Mt (Bioenergy International 2019 ). In the Kazan incinerator, 0.55 Mt of MSW will be treated annually, which eventually will allow ceasing of landfilling of solid waste in the Republic of Tatarstan (Bioenergy International 2019 ; Regnum 2017 ). The construction of these five new incineration plants is part of the Comprehensive Municipal Solid Waste Strategy adopted by the Russian government in 2013 (Plastinina et al. 2019 ). The focus of this strategy is the reduction in the amount of landfilled waste by creating an integrated management system and industrial recycling of waste.

Separate collection of MSW and the recycling of different waste fractions at the moment plays only a negligible role in the Russian Federation.

Materials and methods

Scenarios of the development of municipal solid waste management system.

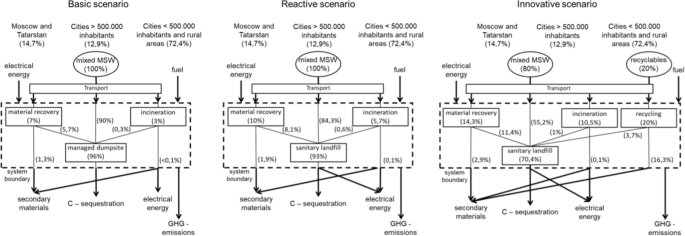

To assess the current situation and the potential for reducing GHG emissions from the MSW management industry, three scenarios of the development of the Russian waste management system had been elaborated. The developed scenarios are based on the official statistics data on the amount of waste generated and treated, and also on the adopted legislative acts that determine the development directions of the Russian waste management system and set targets in these areas (Council for Strategic Development and National Projects 2018 ). That is why the developed scenarios include such measures to improve the waste management system as elimination of unauthorized dump sites, introduction of landfill gas collection and utilization systems at the landfills, incineration of waste with energy recovery, separate collection of waste, and recycling of utilizable waste fractions, and do not include other waste-to-energy technologies and waste treatment strategies contributing to climate change mitigation. Separate collection and treatment of biowaste is not applied in the national waste management strategy of the Russian Federation (Government of the Russian Federation 2018 ) and therefore was beyond the scope of the elaborated scenarios. For the purpose of the current study, three scenarios had been developed.

Scenario 1: BASIC (business as usual)

This scenario is based on the current waste management practices, under which 90% of the generated mixed MSW is disposed of on landfills and dump sites. According to the 6th National Communication Report of the Russian Federation to UNFCCC, the total MSW generated that found its way to managed landfills Footnote 1 was 49.209 Mt in 2009, while the amount of MSW disposed in unmanaged disposal sites (dumps) was 5.067 Mt. In 2017, the amount of MSW generated was 58.4 Mt with 10% being diverted from landfills: 3% incinerated and 7% recycled (Ministry of Natural Resources and Ecology of the Russian Federation 2019 ). According to Russian Federation 2019 , landfill gas recovery is not taking place at Russian landfills. This scenario implies the closure of unorganized dump sites, with all the waste to be disposed of on managed dump sites or landfills only.

Scenario 2: REACTIVE (moderate development)

The reactive scenario implies a moderate development of the waste management sector, based on the construction of several large incinerators, a small increase in the share of waste to be recycled and the disposal of remaining waste at sanitary landfills, Footnote 2 with the closure of all the existing unorganized dump sites. In this scenario, all Russian regions were divided into two clusters: the first cluster included the city of Moscow and the Republic of Tatarstan, where new waste incinerators are being built, and the second cluster which includes — all the other cities and regions.

Moscow and the Republic of Tatarstan

In Moscow and Tatarstan together, 8.586 Mt of mixed MSW is generated annually (Cabinet of Ministers of the Republic of Tatarstan 2018 ; Department of Housing and Communal Services of the city of Moscow 2019 ). In an attempt to introduce the waste-to-energy technology in Russia, an international consortium that consists of Swiss, Japanese and Russian firms is currently involved in constructing five state-of-the-art incineration plants in these two areas. Four incinerators are to be built in the Moscow region and one in Kazan, the capital of the Republic of Tatarstan. The annual combined capacity of the four plants in Moscow will be about 2.8 Mt of MSW, and the one of Kazan 0.55 Mt (Bioenergy International 2019 ; Regnum 2017 ). In this scenario, it is assumed that compared to the basic scenario, the share of waste undergone recycling is increased to 10%, i.e., 0.859 Mt annually. Furthermore, these 10% would be transferred to recycling plants to recover secondary raw materials. The remaining 4.377 Mt of mixed MSW would be disposed of in sanitary landfills.

Other cities and regions

In the other cities and regions of Russia, in accordance with the Development Strategy of Waste Recycling Industry until 2030 (Government of the Russian Federation 2018 ), over two hundred new eco-techno parks (i.e., waste recycling complexes) will be built. These facilities will receive mixed MSW that will be sorted there for recycling purposes. Under this scenario, it is also assumed that compared to the basic scenario, the share of waste undergone recycling is increased to 10%, thus transferring 4.982 Mt annually of the mixed MSW to recycling plants. The remaining 44.932 Mt of MSW are disposed of in sanitary landfills.

Scenario 3: INNOVATIVE (active development)

This scenario is based on the legally established priority areas for the development of the industry (Council for Strategic Development and National Projects 2018 ; Government of the Russian Federation 2018 ). The scenario implies deep changes in the industry with the introduction of technologies for incineration, separate collection and recycling of waste. In this scenario, the regions of Russia are divided into three clusters, in accordance with the possibilities of improving the infrastructure for waste management and the need for secondary resources and energy received during the processing of waste. When determining the share of waste to which this or that treatment method is applied, federal targets (Council for Strategic Development and National Projects 2018 ; Government of the Russian Federation 2018 ) and estimates made by the World Bank (Korobova et al. 2014 ) were used.

The first cluster includes two huge, densely populated urban agglomerations in which large incineration plants are under construction: Moscow and Tatarstan. With the construction of new waste incinerators, 3.35 Mt of mixed MSW will be incinerated annually. It is assumed that some 10% of mixed MSW (0.859 Mt) generated in these two regions is to be transferred to eco-techno parks for secondary raw material recovery. Some 20% of the MSW (1.712 Mt) is to be recovered from separately collected waste, and the rest of 2.66 Mt (31%) to be disposed of in sanitary landfills.

Cities with more than 0.5 million inhabitants

This cluster includes large urban agglomerations with developed industry and high demand for materials and energy resources. In this cluster, approx. 28 Mt of MSW is generated annually (Korobova et al. 2014 ). Under this scenario, it is assumed that waste incineration plants are also built in some larger cities, besides Moscow and Kazan. However, the exact quantity and capacity of these plants is yet unknown; it was assumed that in comparison with the basic scenario, in this scenario, the share of incinerated waste increased to 10%, the share of recycled waste to 15%, and a separate waste collection system is partially implemented. Hereby, 10% of the generated mixed MSW (2.79 Mt) is undergoing incineration, 15% (4.185 Mt) is transferred to sorting facilities for secondary raw material recovery, some 20% of the MSW (5.58 Mt) is recovered from separately collected waste and the rest 55% (15.345 Mt) is disposed of in sanitary landfills.

Smaller cities with less than 0.5 million inhabitants and rural areas

This cluster includes smaller cities and towns with some industrial enterprises, as well as rural areas. The amount of waste generated annually in this group of settlements is 21.914 Mt. It is assumed that no waste is incinerated, 15% of the mixed MSW (3.287 Mt) is transferred to sorting facilities for secondary raw material recovery, 10% (2.191 Mt) is recovered from separately collected waste, and the rest 75% (16.435 Mt) is disposed of in sanitary landfills.

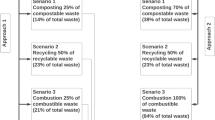

Waste flow diagrams corresponding to the three scenarios with their input and output flows are shown in Fig. 1 .

MSW management scenarios with model inputs and outputs

In all the three scenarios, mixed MSW is transferred to sorting facilities where the recovery of valuable materials by mostly hand sorting takes place. Detailed accounts of process efficiency for material recovery facilities, in terms of recovery rates and quality of recovered materials, are scarce in the published literature (Cimpan et al. 2015 ). In the study of Cimpan et al., 2015 , at least three data sets were evaluated with the result that 13–45% of paper, 3–49% of glass, 35–84% of metals and 1–73% of plastics were recovered from the plant input of these materials. Two other studies report similar recovery rates between 60 and 95% for paper, glass, plastic and aluminum for hand and automatic sorting test trials (CalRecovery, Inc and PEER Consultants 1993 ; Hryb 2015 ). Based on this data and the results of the authors’ own experimental studies on manual waste sorting in Russia, the recovery rates for the most valuable waste fractions, including paper/cardboard, glass, metals and plastics had been calculated (Table 1 ). In the Scenario 3, separate collection of paper/cardboard, glass and plastic is introduced. Recovery rates related to the input of the corresponding waste type into each waste management cluster (see Table 1 ) for Moscow and Tatarstan as well as for the cities with more than 0.5 million inhabitants are considered to be higher than for the settlements with less than 0.5 million inhabitants.

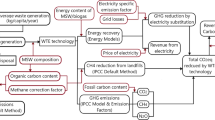

For the comparison of GHG emissions of the three elaborated scenarios, a specific assessment model was elaborated.

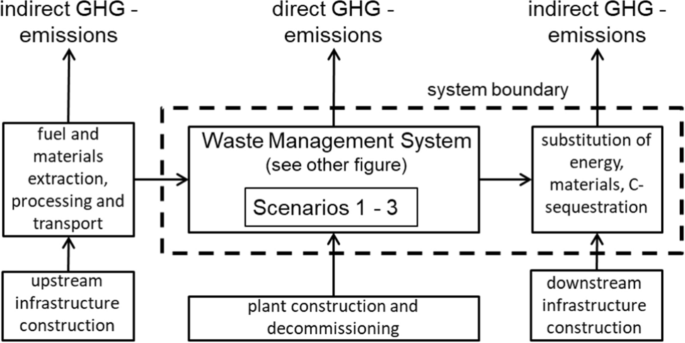

Model structure

The calculation of the amounts of released and avoided GHG emissions for the different considered waste treatment technologies are based on the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. The IPCC methodology is scientifically widely recognized and used internationally, which makes the results easy comprehensible and easier to compare with other studies.

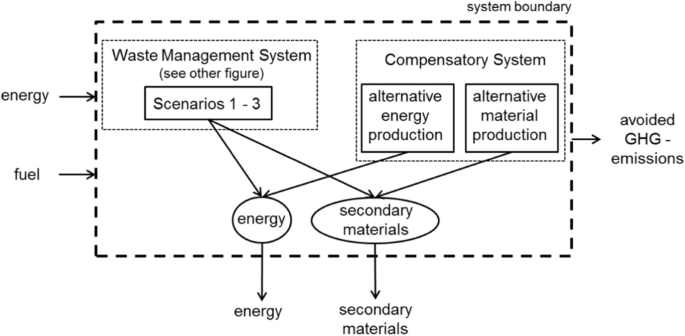

For the elaboration of the model that would allow calculating the GHG balance emissions, the upstream-operating-downstream (UOD) framework (Gentil et al. 2009 ) was used, where direct emissions from waste management procedures and indirect emissions from upstream and downstream activities are differentiated. On the upstream side, the indirect GHG emissions, like those related to fuel and material extraction, processing and transport as well as plant construction and commissioning, are excluded from the consideration. Indirect emissions from infrastructure construction on the downstream side are outside the system boundaries and not accounted for as they are relatively low (Boldrin et al. 2009 ; Mohareb et al. 2011 ). Direct GHG emissions from the waste transport are also excluded from the system boundaries since they are negligible comparing to the direct emissions from the waste processing/treatment (Weitz et al. 2002 ; Wuensch and Simon 2017 ). Since indirect GHG emissions avoided due to energy and material substitution, as well as carbon sequestration in the downstream processes is significant, they are included into the model. The conceptual framework of the model and its boundaries are shown in Fig. 2 .

Conceptual framework of the model showing upstream and downstream processes along with the system boundaries [derived from Abu Qdais et al. ( 2019 )]

The inputs to the model are waste (its quantity, composition, carbon content fixed in biomass and no-biomass), as well as energy and fuel that are used in the waste treatment processes (see Table 2 and Figs. 1 , 2 and 3 ). The outputs include generated and delivered electricity, recovered secondary materials and sequestrated carbon.

Compensatory system for the substitution of primary materials and energy [derived from Abu Qdais et al. ( 2019 )]

The analysis of MSW composition is not regularly done in Russia, and only a limited number of studies on this subject are published. Since waste composition is the basis for the determination of direct GHG emissions from waste management activities, accurate data is desirable. The Russian Federation is a huge country with both densely populated urban areas and sparsely populated rural areas. Due to the different settlement structures, the waste compositions also differ a lot. It is not expedient to assume an average composition for the entire country. Therefore, hereinafter three clusters had been considered to define waste compositions. The first cluster includes Moscow and the Republic of Tatarstan, since in these regions, a larger amount of mixed MSW is/will be incinerated in the nearest future. The second cluster includes the cities with the population of more than 0.5 million people, and the third cluster includes the settlements with the population of less than 0.5 million people. The waste compositions for these three clusters given in Table 2 are weighted averages of the results of a number of experimental studies of waste composition which were found in sources of the literature published after 2010 and further analyzed. Weighted average here means that the respective data on waste composition that was found for a city or region was included in the weighted average with the proportion that the amount of MSW generated in the city or region takes up as part of the total mass of MSW generated in the respective cluster.

To determine the avoidance of GHG emissions in the downstream processes by means of energy and material substitution as well as carbon sequestration, a compensatory system must be used. In Fig. 3 , the compensatory system for the substitution of energy and primary materials is shown.

Emission factors

Waste incineration.

It is necessary to know the emission factors when calculating GHG emissions from thermal treatment of waste, and also when compiling national emissions inventories (Larsen and Astrup 2011 ). Information on GHG emission factors of various solid waste treatment technologies for each country is of great importance for the assessment of GHGs emitted as a result of adopting a certain technology. However, such factors are not available for the Russian Federation, which implies using the data available in the literature for the countries with the conditions similar to the Russian ones, examining local circumstances of solid waste management system (Friedrich and Trois 2013 ; Larsen and Astrup 2011 ; Noya et al. 2018 ).

There are different factors affecting GHG emission levels from waste incineration. One of the most important factors in determining CO 2 emissions is the amount of fossil carbon in the waste stream meant for incineration. Non-CO 2 emissions are more dependent on the incineration technology and conditions, and for modern waste incinerators, the amounts of non-CO 2 emissions are negligible (Johnke 2001 ; Sabin Guendehou et al. 2006 ).

The amount of fossil carbon was calculated based on waste composition, carbon content and share of fossil carbon given in Table 2 ; the resulting fossil carbon content in wet waste was 0.117 kg C/kg. For the indirectly avoided GHG emissions, the recovery of electricity with a net efficiency of 24% for all the scenarios and for the Scenario 3 also from metals contained in the incinerator slag to substitute primary metals was considered. The recovery of heat in form of process steam or district heat was not considered in the scenarios (Dashieva 2017 ). Further parameters for the calculation of GHG emissions from waste incineration are given in Table 3 .

For the calculation of the impact of the methane released from landfills to climate change over a 100 years’ time horizon, the first-order decay kinetics model was used. Almost 80% of the Russian MSW landfills occupy an area larger than 10 ha (Volynkina and Zaytseva 2010 ). Here, it is assumed that all the MSW is highly compacted and disposed of in deep landfills under anaerobic conditions without the recovery of landfill gas (Govor 2017 ). Since no landfill gas is recovered, in Scenario 1, only the sequestrated non-biodegradable biogenic carbon in the landfill results in avoided GHG emissions. There is an intention in Russia to introduce the collection of landfill gas as the primary measure to reduce GHG emissions from the waste management sector (Government of the Russian Federation 2018 ; Ministry of Natural Resources and Ecology of the Russian Federation 2013 ) within the next years. In the literature, methane recovery rates between 9% (Scharff et al. 2003 ) and 90% (Spokas et al. 2006 ) are reported. For example, most US landfills are well-controlled and managed; in particular, in California, gas collection efficiencies are as high as 82.5% (Kong et al. 2012 ). Based on these values, for both Scenario 2 and Scenario 3, landfill gas recovery is introduced with a recovery rate of 60%. Under these two scenarios, in addition to carbon sequestration, the recovered landfill gas is used to produce electricity, which results in avoided indirect GHG emissions. Other parameters used for the calculation are mainly taken from the latest Russian National Inventory Report where IPCC default parameters were used (Pipatti et al. 2006 ; Russian Federation 2019 ). The parameters used for the calculation of GHG emissions from landfills for all the three scenarios are shown in Table 4 .

- Material recovery

In all the scenarios, some part of mixed MSW is treated in eco-techno parks, where valuable secondary raw materials like metals, paper, glass and plastics are recovered, and the sorting residues are forwarded to landfills. In addition, separate collection of some amounts of paper, glass, and plastics in the Scenario 3 is presumed. The corresponding recovery rates are already given in Table 1 . Each recovered secondary material substitutes a certain amount of primary material. Since the production of primary materials is usually connected with higher energy and raw material consumption than that of the secondary materials, more GHGs are released during the production of the former ones. Therefore, every unit of recovered secondary material obtained leads to a reduction in released GHGs.

GHG emission or substitution factors are developed for specific geographical areas and technologies, and their appropriateness to other circumstances may be questionable (Turner et al. 2015 ). The application of one specific emission factor for a recovered material in the whole Russian Federation would already be debatable due to the size of the country. Perhaps that is why emission factors for Russia cannot be found in the literature. For this study, the average values of GHG emission/substitution factors determined for other industrial countries from the study of (Turner et al. 2015 ) were used. The amounts of avoided GHG, i.e., the values of the emission factors in CO 2 equivalents for the recovered valuable waste fractions, including steel, aluminum, paper/cardboard, glass and plastic, are given in Table 5 .

In Table 5 , the used equivalent factor (Global Warming Potential over a time horizon of 100 years) of released methane versus carbon dioxide, the emission factor of the use of fuel oil in the waste incineration process and the substitution factor of delivered electrical power are shown. The emission factor of the generated electricity in the Russian Federation is relatively low, since approx. half (52%) of the electricity is produced by natural gas and approx. 13% by hydro- and nuclear power, while only 13% is produced by coal (British Petrolium 2019 ; U.S. Energy Information Administration 2017 ). The electricity mix factor is therefore only 0.358 Mg CO 2 -eq./MWh generated electricity (Gimadi et al. 2019 ).

Results and discussion

The population of the Russian Federation is expected to decrease in the next decades (United Nations 2019 ), but due to the economic growth, the amount of waste generated per capita is expected to increase in the same ratio; that is why the calculation of the GHG emissions for all the three scenarios was based on an assumed fixed annually amount of 58.4 Mt of MSW. Average waste compositions were calculated for this study on the basis of eleven waste analyses conducted in different Russian cities between 2010 and 2017 and grouped into three clusters (Moscow and Tatarstan, cities with more than 0.5 million inhabitants and cities/settlements with less than 0.5 million inhabitants). From the available literature data for the countries with conditions similar to Russian ones, emission factors were adopted to be further used in calculations of GHG emissions from waste disposal on managed and sanitary landfills, waste incineration and waste recycling with the recovery of secondary raw materials.

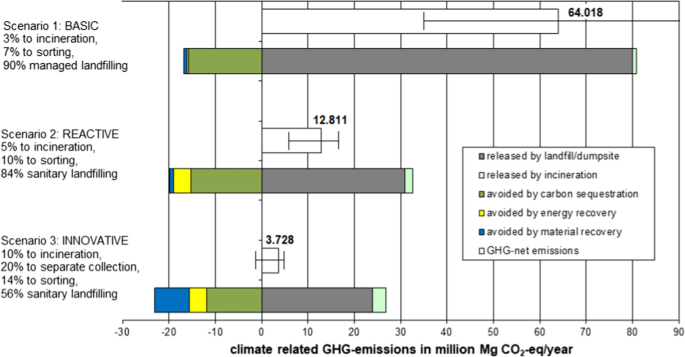

In Fig. 4 , the amounts of CO 2 -equivalent emissions per year that contribute to global warming for each of the three scenarios considered in the study are shown. Since the emissions related to the collection and transportation of waste, as well as energy consumption in the upstream side, are almost similar for all the treatment processes (Komakech et al. 2015 ), and as they are relatively small compared to the operational and downstream emissions (Boldrin et al. 2009 ; Friedrich and Trois 2011 ), they were not considered in the model. Avoided and sequestrated emissions were subtracted from the direct emissions to calculate GHG net emission values.

Global warming contribution of the three considered scenarios

The basic scenario (mostly managed landfilling without landfill gas recovery) gives the highest GHG net emissions among all the analyzed scenarios of approx. 64 Mt CO 2 -eq./a, followed by the reactive scenario (mostly sanitary landfilling with landfill gas recovery) with approx. 12.8 Mt CO 2 -eq./a of GHG net emissions. The innovative scenario (sanitary landfilling with landfill gas recovery and increased shares of MSW incineration, separate collection and material recovery) had shown an almost neutral GHG balance with approx. 3.7 Mt CO 2 -eq./a of GHG net emissions.

To assess the impact of the introduction of various waste treatment methods on the amount of GHG emissions from the waste management sector, the specific GHG emissions for each scenario as a whole was calculated, as well as “within” scenarios for each considered waste management process/method (Table 6 ).

The amount of specific total GHG emissions under Scenario 2 is five times less than under Scenario 1. Such a large difference is due to the modernization of existing managed dumpsites (Scenario 1), instead of which MSW is disposed of at sanitary landfills equipped with landfill gas and leachate collection systems, with intermediate insulating layers and top capping (Scenario 2). Such a transition from managed dumpsites to sanitary landfills leads not only to a decrease in the amount of specific released GHG emissions by approx. 1 Mg CO 2 -eq./Mg MSW, but also to a decrease in total emissions due to avoided emissions in the amount of 0.053 Mg CO 2 -eq./Mg MSW generated by energy recovery.

The amount of specific total GHG emissions under Scenario 3 is 3.4 times less than under Scenario 2. This reduction is mainly due to an almost twofold increase in the volume of waste incinerated, along with the introduction of a separate waste collection system (Scenario 3). At the same time, in Scenario 3, the share of plastic in the mixed waste stream sent to incineration is less than in Scenarios 1 and 2 (see Fig. 1 ). Climate-related GHG from waste incineration are generated mainly due to the plastic contained in the waste. Therefore, in Scenario 3, less GHG emissions are released during waste incineration. Reduction in GHG emissions from waste incineration is also facilitated by the recovery of metals from the bottom ash, which occurs only in Scenario 3.

In Scenario 3, the total amount of recycled material is larger than in Scenario 2, since not only part of the mixed waste is recycled, but also separately collected. According to the Scenario 3, metals are not included in the waste fractions collected separately. Metals have a comparably high GHG substitution factor (see Table 5 ); this explains the slight decrease in avoided GHG emissions due to material recovery in Scenario 3 compared to Scenario 2 because of a decreased share of metals in the total waste stream sent for recycling.

Many studies confirm GHG emissions reduction by the application of these waste treatment concepts. It is shown that the recovery of landfill gas from managed landfills has a high potential to reduce GHG emissions from landfills (EI-Fadel and Sbayti 2000 ; Friedrich and Trois 2016 ; Lee et al. 2017 ; Starostina et al. 2014 ). The transfer from the disposal of mixed MSW on landfills to the incineration on waste incineration or waste-to-energy plants leads to further reduction in GHG emissions (Bilitewski and Wuensch 2012 ; Chen 2018 ; Voigt et al. 2015 ). The recovery of secondary materials from MSW allows avoiding additional amounts of GHG emissions (Björklund and Finnveden 2005 ; Franchetti and Kilaru 2012 ; Turner et al. 2015 ; Wuensch and Simon 2017 ).

It should be noted that the calculated results of the direct GHG emissions from landfilling and waste incineration are subject to uncertainties. Waste composition (Table 2 ) and the parameters set/assumed for the landfills (Table 4 ) and waste incineration (Table 3 ) affect the level of the results. Indirect downstream emissions from recovered secondary materials and substituted energy cannot be provided with accuracy, as indicated by missing data for the substitution factors of recovered secondary materials in Russia and the variability of the scenarios for substituted electricity. To get an impression about the possible fluctuation range of the determined results, a sensitivity analysis was carried out. Therefore, all values shown in Tables 1 , 3 , 4 and 5 were ones decreased by 10% and once increased by 10%. The impact of the sensitivity analysis on the GHG net emissions is shown as error bars in Fig. 4 . The results of the sensitivity analysis show a range for the GHG net emissions of the basic scenario between 35.129 and 91.446 Mt CO 2 -eq./a, for the reactive scenario between 5.133 and 16.324 Mt CO 2 -eq./a and for the innovative scenario from − 1.516 to 4.871 Mt CO 2 -eq./a.

All the exact values of the final results shown in Fig. 4 as well as the graphical representation of the results of the sensitivity analysis can be checked in the provided supplementary materials.

The most recent data about global GHG emissions from solid waste disposal shows that direct emissions contribute with 0.67 Gt CO 2 -eq./a (Fischedick et al. 2014 ) to about 1.4% of the total anthropogenic GHG emissions of 49 Gt CO 2 -eq./a (Edenhofer et al. 2015 ). For the Russian Federation, the contribution of the direct emissions from the MSW management accounts for approx. 3.7% of the total GHG emissions of the country of around 2.2 Gt CO 2 -eq./a (Russian Federation 2019 ). In this study, the potential of different waste management methods in relation to climate change impact was assessed using the example of the Russian waste management industry. For this purpose, three scenarios had been developed and analyzed:

Basic scenario (business as usual), based on the existing waste management practices. The scenario implies that 90% of the generated mixed MSW is disposed of on managed dumpsites, 7% is undergone material recovery and 3% incinerated. All the unorganized dumpsites are closed; on managed dumpsites, there is no landfill gas recovery.

Reactive scenario (moderate development). This scenario implies construction of a number of large waste incineration plants and an increase in the share of waste to be recycled so that 84.3% of generated MSW is disposed of in sanitary landfills, 10% is sent to recycling plants for material recovery, and 5.7% is incinerated.

Innovative scenario (active development). This scenario assumes partial implementation of a separate waste collection system and broader introduction of waste processing technologies. As a result, 20% of the total generated MSW is collected separately and then recycled, 14.3% undergoes material recovery, 55.2% is disposed of in sanitary landfills, and 10.5% is incinerated.

For determining weighed average morphological composition of MSW, three clusters of human settlements had been considered, and the respective data on waste compositions had been analyzed. The first cluster includes Moscow and the Republic of Tatarstan, the second cluster includes the major cities (those with the population of more than 0.5 million people), and the third cluster includes the minor cities and rural areas.

For determining emission factors, both own calculation results and reference data from the National Inventory Report and other sources were used. Thus, the amount of fossil carbon, being one of the most important factors determining CO 2 emissions from waste incineration, was calculated based on the waste composition, carbon content and the share of fossil carbon in the waste. For the calculation of the amount of CH 4 released from MSW landfills, the first-order decay kinetics model was used. Avoided GHG emissions are the result of sequestrated non-biodegradable biogenic carbon in landfills (all the scenarios) and recovered landfill gas used to produce electricity (Scenarios 2 and 3). With the use of emission factors for material recovery included those for the recovered valuable waste fractions steel, aluminum, paper and cardboard, glass and plastic, GHG emissions were calculated under each scenario. As it was expected, the basic scenario gives the highest amount of total GHG net emissions of approx. 64 Mt CO 2 -eq./a (1.096 Mg CO 2 -eq./Mg MSW). Under the reactive scenario, the amount of total GHG net emissions is approx. 12.8 Mt CO 2 -eq./a (0.219 Mg CO 2 -eq./Mg MSW), and under the innovative scenario, it is about 3.7 Mt CO 2 -eq./a (0.064 Mg CO 2 -eq./Mg MSW).

The calculation of specific GHG emissions made it possible to assess the extent to which the introduction of various waste treatment methods makes it possible to reduce GHG emissions resulting from the respective waste treatment processes. Analysis of the results of these calculations showed that the transition from managed dumpsites to sanitary landfills can reduce total GHG emissions from the Russian waste management sector by up to 5 times. The introduction of a separate collection system (in which 20% of waste is collected separately) with a simultaneous twofold increase in the share of waste incinerated has led to a more than threefold reduction in total GHG emissions from the sector of Russian waste management. Another factor influencing the reduction in GHG emissions from waste incineration is the recovery of metals from the bottom ash.

Direct GHG emissions can be further reduced with a shift from landfilling to treatment of mixed MSW in material recovery facilities and waste incinerators or even to separate collection and treatment of MSW. In addition, indirect downstream emissions can be avoided by a significant amount via energy and material recovery. With a separate collection and treatment of biowaste and the recovery of district heat from waste incineration process, further GHG mitigation can be obtained. With these additional measures, the MSW industry of the Russian Federation could become a net avoider from a net emitter.

For this study, a number of parameters and emission factors from the literature where used, which does not precisely reflect the situation in Russia. Conducting further research for determining country specific, for a huge country like Russia, possibly even region-specific data and emission factors resulting in the development of a corresponding database would be useful to minimize these uncertainties.

Data availability

Not applicable.

Acknowledgements

The authors wish to thank all who assisted in conducting this work.

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and affiliations.

Institute of Waste Management and Circular Economy, Department of Hydrosciences, Technische Universität Dresden, Pratzschwitzer Str. 15, 01796, Pirna, Germany

Department of Engineering and Natural Sciences, Merseburg University of Applied Sciences, 06217, Merseburg, Germany

Environmental Protection Department, Perm National Research Polytechnic University, Prof. Pozdeev Street 14, Perm, Russia, 614013

You can also search for this author in PubMed Google Scholar

Contributions

CW involved in conceptualization, data curation, methodology, validation, visualization, writing — original draft, and writing — review and editing. AT involved in conceptualization, data curation, investigation, and writing — original draft.

Corresponding author

Correspondence to C. Wünsch .

Ethics declarations

Conflict of interest.

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Maryam Shabani

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file 1 (PDF 225 KB)

Supplementary file 2 (xlsx 37 kb), supplementary file 3 (xlsx 21 kb), rights and permissions.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Wünsch, C., Tsybina, A. Municipal solid waste management in Russia: potentials of climate change mitigation. Int. J. Environ. Sci. Technol. 19 , 27–42 (2022). https://doi.org/10.1007/s13762-021-03542-5

Download citation

Received : 17 September 2020

Revised : 13 March 2021

Accepted : 09 July 2021

Published : 29 July 2021

Issue Date : January 2022

DOI : https://doi.org/10.1007/s13762-021-03542-5

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Climate change

- Greenhouse gases

- Russian Federation

- Incineration

- Separate collection of waste

- Waste composition

- Find a journal

- Publish with us

- Track your research

Radioactive Waste Management

- Nuclear power is the only large-scale energy-producing technology that takes full responsibility for all its waste and fully costs this into the product.

- The amount of waste generated by nuclear power is very small relative to other thermal electricity generation technologies.

- Used nuclear fuel may be treated as a resource or simply as waste.

- Nuclear waste is neither particularly hazardous nor hard to manage relative to other toxic industrial waste.

- Safe methods for the final disposal of high-level radioactive waste are technically proven; the international consensus is that geological disposal is the best option.

Like all industries, the generation of electricity produces waste. Whatever fuel is used, the waste produced in generating electricity must be managed in ways that safeguard human health and minimize the impact on the environment.

For radioactive waste, this means isolating or diluting it such that the rate or concentration of any radionuclides returned to the biosphere is harmless. To achieve this, practically all radioactive waste is contained and managed, with some clearly needing deep and permanent burial. From nuclear power generation, unlike all other forms of thermal electricity generation, all waste is regulated – none is allowed to cause pollution.

Nuclear power is characterized by the very large amount of energy produced from a very small amount of fuel, and the amount of waste produced during this process is also relatively small. However, much of the waste produced is radioactive and therefore must be carefully managed as hazardous material. All parts of the nuclear fuel cycle produce some radioactive waste and the cost of managing and disposing of this is part of the electricity cost ( i.e. it is internalized and paid for by the electricity consumers).

All toxic waste needs be dealt with safely – not just radioactive waste – and in countries with nuclear power, radioactive waste comprises a very small proportion of total industrial hazardous waste generated.

Radioactive waste is not unique to the nuclear fuel cycle. Radioactive materials are used extensively in medicine, agriculture, research, manufacturing, non-destructive testing, and minerals exploration. Unlike other hazardous industrial materials the level of hazard of all radioactive waste – its radioactivity – diminishes with time.

Types of radioactive waste

Radioactive waste includes any material that is either intrinsically radioactive, or has been contaminated by radioactivity, and that is deemed to have no further use. Government policy dictates whether certain materials – such as used nuclear fuel and plutonium – are categorized as waste.

Every radionuclide has a half-life – the time taken for half of its atoms to decay, and thus for it to lose half of its radioactivity. Radionuclides with long half-lives tend to be alpha and beta emitters – making their handling easier – while those with short half-lives tend to emit the more penetrating gamma rays. Eventually all radioactive waste decays into non-radioactive elements. The more radioactive an isotope is, the faster it decays. Radioactive waste is typically classified as either low-level (LLW), intermediate-level (ILW), or high-level (HLW), dependent, primarily, on its level of radioactivity.

Low-level waste

Low-level waste (LLW) has a radioactive content not exceeding four giga-becquerels per tonne (GBq/t) of alpha activity or 12 GBq/t beta-gamma activity. LLW does not require shielding during handling and transport, and is suitable for disposal in near surface facilities.

LLW is generated from hospitals and industry, as well as the nuclear fuel cycle. It comprises paper, rags, tools, clothing, filters, etc. , which contain small amounts of mostly short-lived radioactivity. To reduce its volume, LLW is often compacted or incinerated before disposal. LLW comprises some 90% of the volume but only 1% of the radioactivity of all radioactive waste.

Intermediate-level waste

Intermediate-level waste (ILW) is more radioactive than LLW, but the heat it generates (<2 kW/m 3 ) is not sufficient to be taken into account in the design or selection of storage and disposal facilities. Due to its higher levels of radioactivity, ILW requires some shielding.

ILW typically comprises resins, chemical sludges, and metal fuel cladding, as well as contaminated materials from reactor decommissioning. Smaller items and any non-solids may be solidified in concrete or bitumen for disposal. It makes up some 7% of the volume and has 4% of the radioactivity of all radioactive waste.

High-level waste

High-level waste (HLW) is sufficiently radioactive for its decay heat (>2kW/m 3 ) to increase its temperature, and the temperature of its surroundings, significantly. As a result, HLW requires cooling and shielding.

HLW arises from the 'burning' of uranium fuel in a nuclear reactor. HLW contains the fission products and transuranic elements generated in the reactor core. HLW accounts for just 3% of the volume, but 95% of the total radioactivity of produced waste. There are two distinct kinds of HLW:

- Used fuel that has been designated as waste.

- Separated waste from reprocessing of used fuel.

HLW has both long-lived and short-lived components, depending on the length of time it will take for the radioactivity of particular radionuclides to decrease to levels that are considered non-hazardous for people and the surrounding environment. If generally short-lived fission products can be separated from long-lived actinides, this distinction becomes important in management and disposal of HLW.

HLW is the focus of significant attention regarding nuclear power, and is managed accordingly.

Very low-level waste

Exempt waste and very low-level waste (VLLW) contains radioactive materials at a level which is not considered harmful to people or the surrounding environment. It consists mainly of demolished material (such as concrete, plaster, bricks, metal, valves, piping, etc. ) produced during rehabilitation or dismantling operations on nuclear industrial sites. Other industries, such as food processing, chemical, steel, etc. , also produce VLLW as a result of the concentration of natural radioactivity present in certain minerals used in their manufacturing processes (see also information page on Naturally-Occurring Radioactive Materials ). The waste is therefore disposed of with domestic refuse, although countries such as France are currently developing specifically designed VLLW disposal facilities.

Where and when is waste produced?

(See also information page on The Nuclear Fuel Cycle .)

Radioactive waste is produced at all stages of the nuclear fuel cycle – the process of producing electricity from nuclear materials. The fuel cycle involves the mining and milling of uranium ore, its processing and fabrication into nuclear fuel, its use in the reactor, its reprocessing (if conducted), the treatment of the used fuel taken from the reactor, and finally, disposal of the waste. Whilst waste is produced during mining and milling and fuel fabrication, the majority (in terms of radioactivity) comes from the actual 'burning' of uranium to produce electricity. Where the used fuel is reprocessed, the amount of waste is reduced materially.

Mining through to fuel fabrication

Traditional uranium mining generates fine sandy tailings, which contain virtually all the naturally occurring radioactive elements found in uranium ore. The tailings are collected in engineered dams and finally covered with a layer of clay and rock to inhibit the leakage of radon gas, and to ensure long-term stability. In the short term, the tailings material is often covered with water. After a few months, the tailings material contains about 75% of the radioactivity of the original ore. Strictly speaking these are not classified as radioactive waste.

Uranium oxide concentrate from mining, essentially 'yellowcake' (U 3 O 8 ), is not significantly radioactive – barely more so than the granite used in buildings. It is refined then converted to uranium hexafluoride (UF 6 ) gas. As a gas, it undergoes enrichment to increase the U-235 content from 0.7% to about 3.5%. It is then turned into a hard ceramic oxide (UO 2 ) for assembly as reactor fuel elements.

The main by-product of enrichment is depleted uranium (DU), principally the U-238 isotope, which is stored either as UF 6 or U 3 O 8 . Some DU is used in applications where its extremely high density makes it valuable, such as for the keels of yachts and military projectiles. It is also used (with reprocessed plutonium) for making mixed oxide (MOX) fuel and to dilute highly-enriched uranium from dismantled weapons, which can then be used for reactor fuel (see pages on Uranium and Depleted Uranium and Military Warheads as a Source of Nuclear Fuel ).

Electricity generation

In terms of radioactivity, the major source arising from the use of nuclear reactors to generate electricity comes from the material classified as HLW. Highly radioactive fission products and transuranic elements are produced from uranium and plutonium during reactor operations, and are contained within the used fuel. Where countries have adopted a closed cycle and reprocess used fuel, the fission products and minor actinides are separated from uranium and plutonium and treated as HLW (see below). In countries where used fuel is not reprocessed, the used fuel itself is considered a waste and therefore classified as HLW.

LLW and ILW is produced as a result of general operations, such as the cleaning of reactor cooling systems and fuel storage ponds, and the decontamination of equipment, filters, and metal components that have become radioactive as a result of their use in or near the reactor.

Reprocessing of used fuel

Any used fuel will still contain some of the original U-235 as well as various plutonium isotopes which have been formed inside the reactor core, and U-238. In total these account for some 96% of the original uranium and over half of the original energy content (ignoring U-238). Used nuclear fuel has long been reprocessed to extract fissile materials for recycling and to reduce the volume of HLW (see also information page on Processing of Used Nuclear Fuel ). Several European countries, as well as Russia, China, and Japan have policies to reprocess used nuclear fuel.

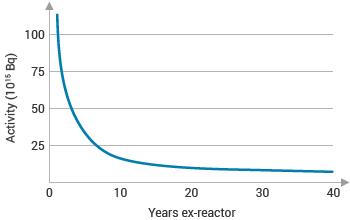

Reprocessing allows for a significant amount of plutonium to be recovered from used fuel, which is then mixed with depleted uranium oxide in a MOX fabrication plant to make fresh fuel. This process allows some 25-30% more energy to be extracted from the original uranium ore, and significantly reduces the volume of HLW (by about 85%). The IAEA estimates that of the 390,000 metric tonnes of heavy metal (MTHM) produced since the advent of civil nuclear power production, 127,000 MTHM has been reprocessed. 1 In addition, the remaining HLW is significantly less radioactive – decaying to the same level as the original ore within 9000 years (vs. 300,000 years). (See also information pages on Mixed Oxide Fuel and Processing of Used Nuclear Fuel .)

Commercial reprocessing plants currently operate in France and Russia. Another is being commissioned in Japan, and China plans to construct one too. France undertakes reprocessing for utilities in other countries, and a lot of Japan’s fuel has been reprocessed there, with both waste and recycled plutonium in MOX fuel being returned to Japan. (See also information pages on Japanese Waste and MOX Shipments From Europe .)

The main historical and current process is Purex, a hydrometallurgical process. The main prospective ones are electrometallurgical – often called pyroprocessing since it happens to be hot. With it, all actinide anions (notably uranium and plutonium) are recovered together. Whilst not yet operational, these technologies will result in waste that only needs 300 years to reach the same level of radioactivity as the originally mined ore.

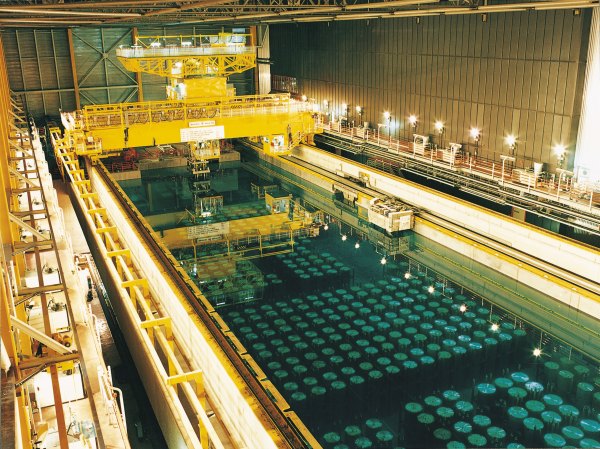

Storage pond for used fuel at the Thermal Oxide Reprocessing Plant (Thorp) at the UK's Sellafield site (Sellafield Ltd).

Decommissioning nuclear plants

(See also information page on Decommissioning Nuclear Facilities .)

In the case of nuclear reactors, about 99% of the radioactivity is associated with the fuel. Apart from any surface contamination of plant, the remaining radioactivity comes from 'activation products' such as steel components which have long been exposed to neutron irradiation. Their atoms are changed into different isotopes such as iron-55, cobalt-60, nickel-63, and carbon-14. The first two are highly radioactive, emitting gamma rays, but with correspondingly short half-lives so that after 50 years from final shutdown their hazard is much diminished. Some caesium-137 may also be found in decommissioning wastes.

Some scrap material from decommissioning may be recycled, but for uses outside the industry very low clearance levels are applied, so most is buried and some is recycled within the industry.

Legacy waste

In addition to the routine waste from current nuclear power generation there is other radioactive waste referred to as 'legacy waste'. This waste exists in several countries that pioneered nuclear power and especially where power programs were developed out of military programs. It is sometimes voluminous and difficult to manage, and arose in the course of those countries getting to a position where nuclear technology is a commercial proposition for power generation. It represents a liability which is not covered by current funding arrangements. In the UK, some £164 billion (undiscounted) is estimated to be involved in addressing this waste – principally from Magnox and some early AGR developments – and about 30% of the total is attributable to military programmes. In the USA, Russia, and France the liabilities are also considerable.

Non-nuclear power waste

In recent years, in both the radiological protection and radioactive waste management communities, there has been increased attention on how to effectively manage non‑power related nuclear waste. All countries, including those that do not have nuclear power plants, have to manage radioactive waste generated by activities unrelated to the production of nuclear energy, including: national laboratory and university research activities; used and lost industrial gauges and radiography sources; and nuclear medicine activities at hospitals. Although much of this waste is not long-lived, the variety of the sources makes any general assessment of physical or radiological characteristics difficult. The relatively source-specific nature of the waste poses questions and challenges for its management at a national level.

Treatment and conditioning

(See also information page on Treatment and Conditioning of Nuclear Waste )

Treatment involves operations intended to change waste streams’ characteristics to improve safety or economy. Treatment techniques may involve compaction to reduce volume, filtration or ion exchange to remove radionuclide content, or precipitation to induce changes in composition.

Conditioning is undertaken to change waste into a form that is suitable for safe handling, transportation, storage, and disposal. This step typically involves the immobilisation of waste in containers. Liquid LLW and ILW are typically solidified in cement, whilst HLW is calcined/dried then vitrified in a glass matrix. Immobilized waste will be placed in a container suitable for its characteristics.

Storage and disposal

(See also information page on Storage and Disposal of Radioactive Waste .)

Storage of waste may take place at any stage during the management process. Storage involves maintaining the waste in a manner such that it is retrievable, whilst ensuring it is isolated from the external environment. Waste may be stored to make the next stage of management easier (for example, by allowing its natural radioactivity to decay). Storage facilities are commonly onsite at the power plant, but may be also be separate from the facility where it was produced.

Disposal of waste takes place when there is no further foreseeable use for it, and in the case of HLW, when radioactivity has decayed to relatively low levels after about 40-50 years.

LLW and short-lived ILW

Most LLW and short-lived ILW are typically sent to land-based disposal immediately following packaging. This means that for the majority (>90% by volume) of all of the waste types, a satisfactory disposal means has been developed and is being implemented around the world.

Near-surface disposal facilities are currently in operation in many countries, including:

- UK – LLW Repository at Drigg in Cumbria operated by UK Nuclear Waste Management (a consortium led by Washington Group International with Studsvik UK, Serco, and Areva) on behalf of the Nuclear Decommissioning Authority.

- Spain – El Cabril LLW and ILW disposal facility operated by ENRESA.

- France – Centre de l'Aube and Morvilliers operated by ANDRA.

- Sweden – SFR at Forsmark operated by SKB.

- Finland – Olkiluoto and Loviisa, operated by TVO and Fortum.

- Russia – Ozersk, Tomsk, Novouralsk, Sosnovy Bor, operated by NO RAO.

- South Korea – Wolseong, operated by KORAD.

- Japan – LLW Disposal Center at Rokkasho-Mura operated by Japan Nuclear Fuel Limited.

- USA – five LLW disposal facilities: Texas Compact facility near the New Mexico border, operated by Waste Control Specialists; Barnwell, South Carolina; Clive, Utah; Oak Ridge, Tennessee – all operated by Energy Solutions; and Richland, Washington – operated by American Ecology Corporation.

Some low-level liquid waste from reprocessing plants is discharged to the sea. This includes radionuclides which are distinctive, notably technetium-99 (sometimes used as a tracer in environmental studies), and this can be discerned many hundred kilometres away. However, such discharges are regulated and controlled, and the maximum radiation dose anyone receives from them is a small fraction of natural background radiation.

Nuclear power stations and reprocessing plants release small quantities of radioactive gases ( e.g. krypton-85 and xenon-133) and trace amounts of iodine-131 to the atmosphere. However, krypton-85 and xenon-133 are chemically inert, all three gases have short half-lives, and the radioactivity in the emissions is diminished by delaying their release. The net effect is too small to warrant consideration in any life-cycle analysis. A little tritium is also produced but regulators do not consider its release to be significant.

Long-lived ILW and HLW

The long timescales over which some ILW and HLW – including used fuel when considered a waste – remains radioactive has led to universal acceptance of the concept of deep geological disposal. Many other long-term waste management options have been investigated, but deep disposal in a mined repository is now the preferred option in most countries. The Waste Isolation Pilot Plant (WIPP) deep geological waste repository is in operation in the US for the disposal of transuranic waste – long-lived ILW from military sources, contaminated with plutonium.

To date there has been no practical need for final HLW repositories. As outlined above, used fuel may either by reprocessed or disposed of directly. Either way, there is a strong technical incentive to delay final disposal of HLW for about 40-50 years after removal, at which point the heat and radioactivity will have reduced by over 99%. Interim storage of used fuel is mostly in ponds associated with individual reactors, or in a common pool at multi-reactor sites, or occasionally at a central site. At present there is about 263,000 tonnes of used fuel in storage. Over two-thirds of this is in storage ponds, with an increasing proportion in dry storage. 1

Illustrative decay in radioactivity of fission products – one tonne of spent PWR fuel.

Storage ponds at reactors, and those at centralized facilities such as CLAB in Sweden, are 7-12 metres deep to allow for several metres of water over the used fuel (assembled in racks typically about 4 metres long and standing on end). The multiple racks are made of metal with neutron absorbers incorporated. The circulating water both shields and cools the fuel. These pools are robust constructions made of thick reinforced concrete with steel liners. Ponds at reactors are often designed to hold all the used fuel produced over the planned operating lifetime of the reactor.

Water-filled storage pools at the Central Interim Storage Facility for Spent Nuclear Fuel (CLAB) facility in Sweden.

Some fuel that has cooled in ponds for at least five years is stored in dry casks or vaults with air circulation inside concrete shielding. One common system is for sealed steel casks or multi-purpose canisters (MPCs) each holding up to about 40 fuel assemblies with inert gas. Casks/MPCs may also be used for the transport and eventual disposal of the used fuel. For storage, each is enclosed in a ventilated storage module made of concrete and steel. These are commonly standing on the surface, about 6m high, and cooled by air convection, or they may be below grade, with just the tops showing. The modules are robust and provide full shielding. Each cask has up to 45 kW heat load.

If used reactor fuel is reprocessed, the resulting liquid HLW must be solidified. The HLW also generates a considerable amount of heat and requires cooling. It is vitrified into borosilicate (Pyrex) glass, sealed into heavy stainless steel cylinders about 1.3 metres high, and stored for eventual disposal deep underground. This material has no conceivable future use and is universally classified as waste. France has two commercial plants to vitrify HLW left over from reprocessing fuel, and there are also plants active in the UK and Belgium. The capacity of these Western European plants is 2500 canisters (1000 t) a year, and some have been operating for three decades. Sellafield, UK, has produced over 6000 canisters of vitrified HLW.

The Australian Synroc (synthetic rock) system is a more sophisticated way to immobilize such waste, and this process may eventually come into commercial use for civil waste (see information page on Synroc ).

If used reactor fuel is not reprocessed, it will still contain all the highly radioactive isotopes. Spent fuel that is not reprocessed is treated as HLW for direct disposal. It too generates a lot of heat and requires cooling. However, since it largely consists of uranium (with a little plutonium), it represents a potentially valuable resource, and there is an increasing reluctance to dispose of it irretrievably.

For final disposal, to ensure that no significant environmental releases occur over tens of thousands of years, 'multiple barrier' geological disposal is planned. This technique will immobilize the radioactive elements in HLW and long-lived ILW, and isolate them from the biosphere. The multiple barriers are:

- Immobilisation of waste in an insoluble matrix such as borosilicate glass or synthetic rock (fuel pellets are already a very stable ceramic, UO 2 ).

- Contain waste sealed inside a corrosion-resistant container, such as stainless steel.

- Isolate waste from people and the environment, so eventually locate it deep underground in a stable rock structure.

- Delay any significant migration of radionuclides from the repository, so surround containers with an impermeable backfill such as bentonite clay if the repository is wet.

Loading silos with canisters containing vitrified HLW in the UK. Each disc on the floor covers a silo holding ten canisters.

Due to the long-term nature of these management plans, sustainable options must have one or more pre-defined milestones where a decision could be taken on which option to proceed with.

A current question is whether waste should be emplaced so that it is readily retrievable from repositories. There are sound reasons for keeping such options open – in particular, it is possible that future generations might consider the buried waste to be a valuable resource. On the other hand, permanent closure might increase long-term security of the facility. After being buried for about 1000 years most of the radioactivity will have decayed. The amount of radioactivity then remaining would be similar to that of the naturally-occurring uranium ore from which it originated, though it would be more concentrated. In mined repositories, which represent the main concept being pursued, retrievability can be straightforward, but any deep borehole disposal is permanent.

France's 2006 waste law says that HLW disposal must be 'reversible', which was clarified in a 2015 amendment to mean guaranteeing long-term flexibility in disposal policy, while 'retrievable' referred to short-term practicality. France, Switzerland, Canada, Japan, and the USA require retrievability. 2 That policy is followed also in most other countries, though this presupposes that in the long-term, the repository would be sealed to satisfy safety requirements.

The measures or plans that various countries have in place to store, reprocess, and dispose of used fuel and waste are described in an appendix to this paper covering National Policies and Funding . Storage and disposal options are described more fully in the information paper on Storage and Disposal of Radioactive Waste .

Natural precedents for geological disposal

Nature has already proven that geological isolation is possible through several natural examples (or 'analogues'). The most significant case occurred almost 2 billion years ago at Oklo, in what is now Gabon in West Africa, where several spontaneous nuclear reactors operated within a rich vein of uranium ore. (At that time the concentration of U-235 in all natural uranium was about 3%.) These natural nuclear reactors continued for about 500,000 years before dying away. They produced all the radionuclides found in HLW, including over 5 tonnes of fission products and 1.5 tonnes of plutonium, all of which remained at the site and eventually decayed into non-radioactive elements. 3

The study of such natural phenomena is important for any assessment of geologic repositories, and is the subject of several international research projects.

Funding waste management

Nuclear power is the only large-scale energy-producing technology that takes full responsibility for all its waste and fully costs this into the product. Financial provisions are made for managing all kinds of civilian radioactive waste. The cost of managing and disposing of nuclear power plant waste typically represents about 5% of the total cost of the electricity generated.

Most nuclear utilities are required by governments to put aside a levy ( e.g. 0.1 cents per kilowatt hour in the USA, 0.14 ¢/kWh in France) to provide for the management and disposal of their waste.

The actual arrangements for paying for waste management and decommissioning vary. The key objective is, however, always the same: to ensure that sufficient funds are available when they are needed. There are three main approaches:

- Provisions on the balance sheet. Sums to cover the anticipated cost of waste management and decommissioning are included on the generating company's balance sheet as a liability. As waste management and decommissioning work proceeds, the company has to ensure that it has sufficient investments and cashflow to meet the required payments.

- Internal fund. Payments are made over the operating lifetime of the nuclear facility into a special fund that is held and administered within the company. The rules for the management of the fund vary, but many countries allow the fund to be re-invested in the assets of the company, subject to adequate securities and investment returns.

- External fund. Payments are made into a fund that is held outside the company, often within government or administered by a group of independent trustees. Again, rules for the management of the fund vary. Some countries only allow the fund to be used for waste management and decommissioning purposes, whilst others allow companies to borrow a percentage of the fund to reinvest in their business.

How much waste is produced?

The volume of high-level radioactive waste (HLW) produced by the civil nuclear industry is small. The IAEA estimates that 392,000 tonnes of heavy metal (tHM) in the form of used fuel have been discharged since the first nuclear power plants commenced operation. Of this, the agency estimates that 127,000 tHM have been reprocessed. The IAEA estimates that the disposal volume b of the current solid HLW inventory is approximately 29,000 m 3 . 1 For context, this is a volume roughly equivalent to a three metre tall building covering an area the size of a soccer pitch.

The amounts of ILW, LLW, and VLLW produced are greater in volume, but are much less radioactive (see above section on Types of radioactive waste ). Given its lower inherent radioactivity, the majority of waste produced by nuclear power production and classified as LLW or VLLW has already been placed in disposal. The IAEA estimates that over 80% of all LLW and VLLW produced to date is in disposal.

Nuclear waste inventory (IAEA estimates, 2022) 1

Note: all volumetric figures are provided as estimates based on operating and proposed final disposal solutions for different types of waste. Figures, published in January 2022, are estimates for end of 2016.

All hazardous waste requires careful management and disposal, not just radioactive waste. The amount of waste produced by the nuclear power industry is small relative to both other forms of electricity generation and general industrial activity. For example, in the UK – the world's oldest nuclear industry – the total amount of radioactive waste produced to date, and forecast to 2125, is about 4.9 million tonnes. After all waste has been packaged, it is estimated that the final volume would occupy a space similar to that of a large, modern soccer stadium. This compares with an annual generation of 200 million tonnes of conventional waste, of which 4.3 million tonnes is classified as hazardous. About 94% of radioactive waste in the UK is classified as LLW, about 6% is ILW, and less than 0.03% is classified as HLW. 4

In over 50 years of civil nuclear power experience, the management and disposal of civil nuclear waste has not caused any serious health or environmental problems, nor posed any real risk to the general public. Alternatives for power generation are not without challenges, and their undesirable by-products are generally not well controlled.