- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

Inside IKEA’s Digital Transformation

- Thomas Stackpole

A Q&A with Barbara Martin Coppola, IKEA Retail’s chief digital officer.

How does going digital change a legacy retail brand? According to Barbara Martin Coppola, CDO at IKEA Retail, it’s a challenge of remaining fundamentally the same company while doing almost everything differently. In this Q&A, Martin Coppola talks about how working in tech for 20 years prepared her for this challenge, why giving customers control over their data is good business, and how to stay focused on the core mission when you’re changing everything else.

What does it mean for one of the world’s most recognizable retail brands to go digital? For almost 80 years, IKEA has been in the very analogue business of selling its distinct brand of home goods to people. Three years ago, IKEA Retail (Ingka Group) hired Barbara Martin Coppola — a veteran of Google, Samsung, and Texas Instruments — to guide the company through a digital transformation and help it enter the next era of its history. HBR spoke with Martin Coppola about the particular challenge of transformation at a legacy company, how to sustain your culture when you’re changing almost everything, and how her 20 years in the tech industry prepared her for this task.

- Thomas Stackpole is a senior editor at Harvard Business Review.

Partner Center

Sustainable supply chain management: a case study at IKEA

Please login to bookmark.

Username or Email Address

Remember Me

No account yet? Register

Date of Publication: Nov 21, 2017

Author: Francine Laurin & Kamel Fantazy

Link to Full Reading:

- Courses Map

- Registration

- Password Reset

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

IKEA-Case Study Supply Chain Management

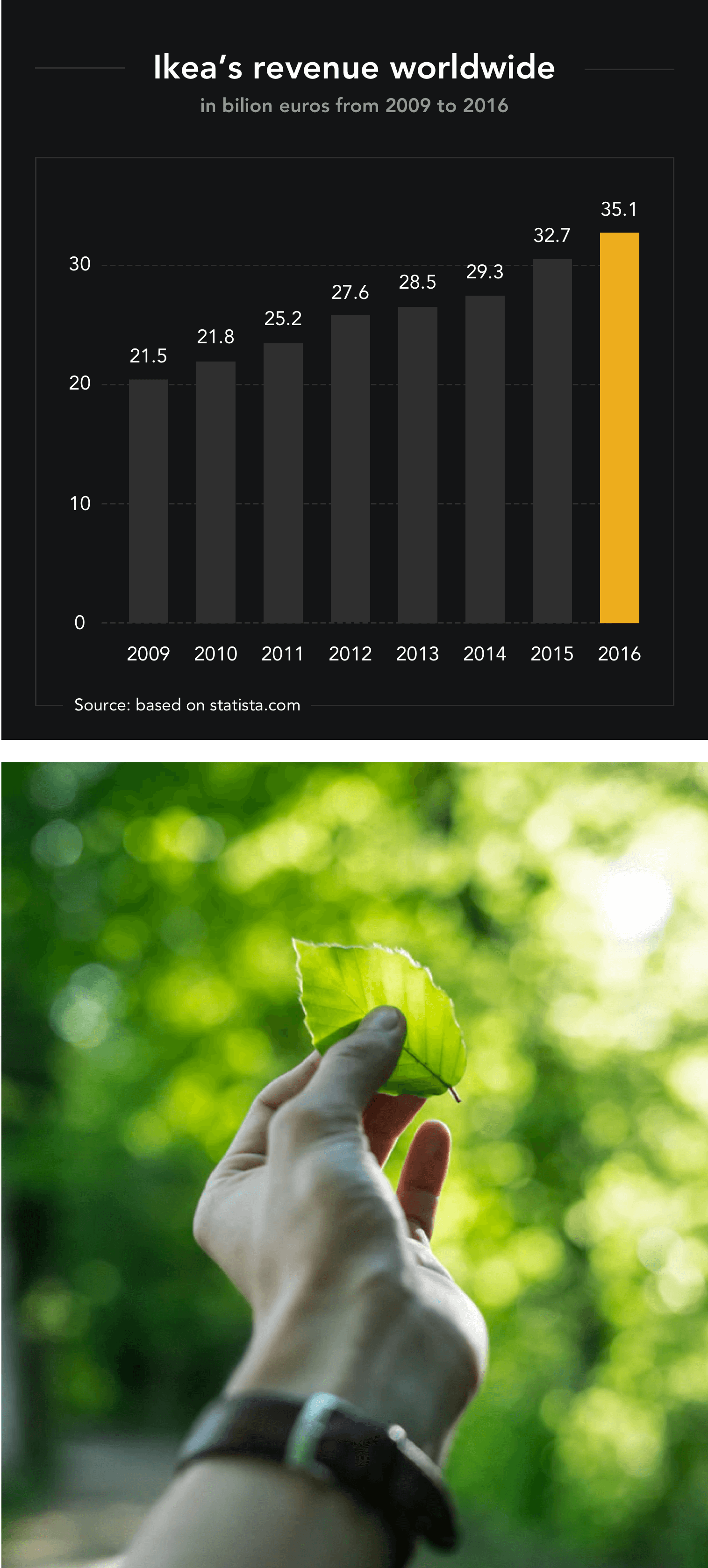

Ikea can be stated as the world’s largest furnishing product vendor (Kotler et. al., 2009) with sales of over 20 billion Euros in 2009 (Kelly, 2010). The company is known all over the world, especially Europe, North America and more frequently in Asia and Australia and is popular for offering “ a wide range of well designed, functional home furnishing products at prices so low as many people as possible will be able to afford them” (Kelly, 2010, p.1). In order to be able to fulfil this aim and promise, IKEA had to and also did implement certain strategies with the aim to be as efficient as possible and provide their customers with the expected quality and mutually satisfy their needs for the reasonable price. In the following it is to discuss the main supply chain strategies IKEA chose in order to work effectively with their respective members and achieve their business goals. Furthermore it is to enlighten the major advantages and value adding factors IKEA gains from their strategies and good relationships and networks with their supply chain members, as well as the assumable measures for improvement IKEA could develop in the future.

Related Papers

Pervez Ghauri

Magnus Boström , Michael Gilek

This report focuses on IKEA’s management and communication surrounding sustainability in general and chemical risks specifically. IKEA’s work is analysed in relation to theoretical concepts around responsibility, supply chain, and governance . The report focuses on IKEA’s visions and organizational structures, its policy instruments to deal with chemical risks, supplier-relations and communication and learning. The study is based on previous scholarly literature, analyses of relevant documents, a field visit at a few of IKEA’s suppliers in southern India, as well as interviews with staff working at IKEA in Sweden. The report focuses on IKEA’s systems and processes for dealing with chemical risks, and not on the implementation of such measures in quantitative terms.

International Marketing Review

Hanaa Elsayad

The paper is a case study for the different types of risks faced by IKEA as the company started its operations in China. How the risks were mitigated, avoided or accepted has been discussed.

Industrial Marketing Management

Adam Lindgreen

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Get 10% off when you buy 2 or more custom products of your choice. Use this promo code at the checkout: 10OFF2

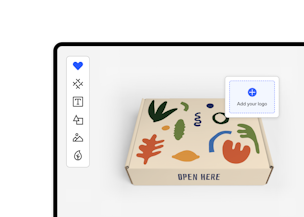

DESIGN IN MINUTES

3D packaging editor

TRY BEFORE YOU BUY

Sample packs

Need something else? Send us a brief and we’ll sort you out

LOWER YOUR COSTS

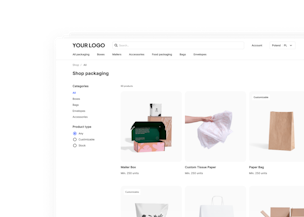

Wholesale packaging

By company type

Our platform

Integrations

PACKHELP WHITE LABEL

Create your own packaging store

Inspirations

Alkoholic beverages

Apparel & Fashion

Health & Beauty

Supplements & CBD

Sustainability

OUR ECO APPROACH

Sustainability Hub

Contact & Help

Region (EU)

Back to menu

Mushrooms-based Packaging? That's IKEA's Concept of Sustainable Supply Chain

IKEA has cut its packaging usage by 50% over the last few years, and continues its journey into more sustainable packaging by exploring new plant-based materials.

Innovative materials

Packaging cost optimization

Focus on sustainability

Global packaging supply chain

Key insights

Plant-based packaging as a way of removing plastic from the packaging supply chain

90% of reduction of carbon emissions achieved through packaging optimization

A mix of fiber-based and plant-based packaging for different customer use cases

Supply chain challenges

Challenges of a global packaging supply chain for ikea.

The furniture & home design chain has now 433 stores in the whole world, and its new smaller concept stores will appeal to new segments of customers. As a result, IKEA deals with an incredibly complex packaging supply chain to work with.

In regard to products range, IKEA’s shop comprises of thousands of products, each one with different shapes and needs in terms of packaging. When you add high maintenance costs for these enormous storage spaces, as well as the need for economies of scope within such diversity of packaging solutions, it’s a quite a challenge all together.

In this layered supply chain, even the smallest change brings significant results. With more than 12.000 products, warehouses and complex logistics chain, IKEA needed a very firm solution for all its deliveries and in-store packaging.

Product portfolio

Supply chain, innovative packaging, mushroom-based packaging.

Earlier in 2019, the company announced the implementation of mushroom-based packaging, based on mycelium and agricultural cultivation of the source material. The innovative concept is a next step in decreasing the amount of EPS-based packaging used by the company.

This innovative material means lots of benefits for the environment:

- less marine waste,

- a massive reduction of 90% in carbon emissions,

- and less energy used in the production process.

Given the company’s size and potential influence, this innovative packaging can decrease the worrying numbers in the packaging industry, where more than 50% of packaging is still made from plastic. Furthermore, IKEA has always been associated with a cutting-edge approach in terms of combining the company’s growth with sustainability.

Cardboard-based packaging

Over 90% of packaging used for deliveries of IKEA is fiber-based boxes

Cardboard and paper are key to IKEA’s products, and these two materials are highly eco-friendly too. The mycelium-based alternative helps to eliminate the plastic inserts and lightweight products for smaller products available in IKEA’s offer. But cardboard and paper helped to remove EPS (expanded polystyrene) packaging from the supply chain of IKEA.

As of 2019, out of over 900,000 tons of packaging produced by IKEA annually, more than 92% is fiber-based. Furthermore, most of it can be easily recycled, much easier than expanded polystyrene. And this is also the key learning from Packhelp Pro projects – our customers choose corrugated cardboard because it’s a great alternative to any plastic-based solutions for shipping.

Allan Dickner, Manager of Packaging Development at IKEA of Sweden explained also that more than 75% of customers bring the products home on their own, and cardboard is appreciated for its high durability. Dickner also said that this corrugated-cardboard box is the first touchpoint for online buyers. And with IKEA’s plans to further push online sales , these boxes become an essential branding and experience medium.

Expert opinion

Artur Oboleński, Head of Packhelp Lab, shares his views on the supply chain strategy of IKEA.

The switch from EPS to cardboard

Product shipping security is expected from any kind of packaging – it is one of its core functions. EPS does just that and it is cheap, available and easy to make. However, it’s also too cheap, too available, too easy to make… and hard to decompose. Filling the box space with alternative but possibly light, soft enough and inexpensive material – is a challenge.

Building their packaging strategy around cardboard and paper helped IKEA to make a significant step towards sustainability. And we see it in the case of many of our customers at Packhelp too. By analyzing the complexity of its own packaging supply chain, each company should be able to identify space where such eco-friendly solutions can be implemented.

of shipping packaging of IKEA is fiber-based, and is easily recyclable

less of carbon emissions is generated by new, mushroom-based packaging

tones of packaging is produced annually by IKEA

Finding alternative materials

Plant-based packaging – whether it is fibre or biopolymers – provides brands with fact-based sustainability credentials. It is even more so in the light of ocean littering concerns and the latest regulations, especially in the EU. The increasing costs of compliance, propelled by the public demand, are meant to offset the price we all have been paying for years anyway – be it polluted air or smelly landscapes with heaps of trash.

I cheer on the IKEA team not only because they made a great idea work but – with their portfolio range and supply chain complexity – it is hard to overstate the effort made (and still to be made too). R&D investment must have been significant and there is still risk associated with the implementation of any new material. Evident sourcing risk connected with new solution and short-lived manufacturing needs another mitigation plan.

Phasing out EPS foam is a step towards changing the packaging solutions throughout the home furnishing industry and making them more sustainable.

Peter S Larsson, Packaging Sustainability Leader at IKEA of Sweden

Global effect

I also welcome the impact this project will potentially and hopefully have on other global brands. Another effect is cash injection into new economy players, such as green startups focused on material engineering. It has the potential of educating global shopper (“ it can’t be mushroom! Really?? ”).

Going forward, IKEA will have to focus on optimizing supply chain of the solution, its global operations will require smart mapping of packaging plants to reflect the network of furniture manufacture. There must be a great potential in developing the vendors – initiatives to address sourcing security through manufacturing efficiency and development of more effective methods. It will have to touch on consistency in quality so the functionality of the inserts is maintained. All the hard work – done and to be done – will pay off in the consumer loyalty who will realize that after all someone does care.

Author's note

Article curated by Kajetan Wyrzykowski, Head of Content at Packhelp & Artur Oboleński, Head of Packhelp Lab.

1. https://intelligentliving.co/ikea-mushroom-based-packaging 2. https://www.chainalytics.com/ikea-save-millions-packaging-optimization/ 3. https://ec.europa.eu/environment/industry/retail/pdf/issue_paper_packaging.pdf 4. https://www.packworld.com/design/materials-containers/article/13377183/ikea-and-the-power-of-the-brown-box 5. https://www.ikea.com/ms/en_US/pdf/reports-downloads/IKEA_BEHIND_EPS_free_packaging.pdf 6. https://www.statista.com/statistics/264433/annual-sales-of-ikea-worldwide/

Images sources

1. https://packagingeurope.com/the-ikea-packaging-challenge/ 2. https://www.smartenergydecisions.com/energy-management/2019/12/02/ikea-invests-200-million-euros-into-supply-chain-sustainability

Case Study information

IKEA is not a customer of Packhelp. This case study is only used for inspirational purposes and exhibiting an innovative approach towards complex supply chains.

- Australia & Oceania

- Czech Republic

- Netherlands

- Switzerland

- United Kingdom

- My country is not listed

IMAGES

COMMENTS

Limitations of this study are primarily based on IKEAs available of information on its sustainability efforts, to. vast to be explored in this case study. IKEA is recognised for a strong corporate ...

To further enhance supply chain sustainability, the company developed a proprietary tool called the "e-wheel," which helps assess the environmental impact of its products at five stages of the supply chain, each forming a key part of its strategy: Raw materials. Manufacturing. Distribution. Consumer use. End of life.

1. Introduction. As defined by Cox (1999), and Harland (1996), Supply Chain Management (SCM) refers to a. process of managing an interconnected business network which provides goods and services ...

IKEA was chosen for the case study, amongst many, for three primary reasons. IKEA is a global firm with manufacturing and distribution centres across the world; its supply chain is vast and complex. IKEA is a pioneer firm that introduced a systematic way of working with sustainability across its operations (Alänge, Clancy, & Marmgren, 2016 ...

For almost 80 years, IKEA has been in the very analogue business of selling its distinct brand of home goods to people. Three years ago, IKEA Retail (Ingka Group) hired Barbara Martin Coppola ...

IKEA case study. IKEA is the world's largest furniture retailer founded by Ingvar Kamprad in Sweden, 1943. In the fiscal year ending in August 2017, there were 403 IKEA stores across 49 markets and nearly four billion products were sold, amounting to a volume of 36,622,756 m 3. IKEA Supply Chain and its logistics network is very complex.

We analyse sustainability practices using data gathered from IKEA as a global case study. Our research findings reveal that sustainability practices can be successfully implemented across an organisation's entire supply chain, including second and third tier suppliers to gain positive environmental and social impacts while still promoting a ...

The case study research is mainly concerned with implementation of supply chain strategy through discussion of IKEA’s strategic business purpose. Thus, the case intends to analyze supply chain management and competitive strategy applicable to IKEA. It has been observed how the worldwide leader in furniture retailing gapped through imperatives and innovations and still expanding by ...

The case study research is mainly concerned with implementation of supply chain strategy through discussion of IKEA's strategic business purpose. Thus, the case intends to analyze supply chain ...

Purpose — The purpose of this paper is to analyse the prerequisites and effects of centralised supply chain planning at IKEA, and to explore how the planning process, planning system, and planning organization make up a centralised planning approach. Design/method/approach — The paper is based on a longitudinal case study of IKEA's ...

In this case study Blue Yonder's solutions have helped Henkel improve the speed, accuracy, efficiency, service level,sustainability and profitability of these operations. Learn more. Business News. ... IKEA's supply chain strategies push against boundaries. This will hopefully inspire you to develop your company's inventory strategies ...

Integrating IKEA's supply chain with blockchain technology strengthens sustainability efforts by effectively incorporating the IKEA supplier Code of Conduct (IWAY) (Laurin & Fantazy, 2017).

Sustainable supply chain management: a case study at IKEA. Francine Laurin, Kamel A. Fantazy. Published 2 October 2017. Environmental Science, Business. Transnational Corporations Review. Abstract While sustainability is central to research on supply chains, there has been relatively little research on diversity and impact on supply chain ...

This one case pilot study explores the extent to which IKEA has successfully integrated sustainability practices into the management of the supply chain. We analyse sustainability practices using data gathered from IKEA as a global case study. Our research findings reveal that sustainability practices can be successfully implemented across an ...

IKEA case study. Unpublished paper, 1, 16. Cosmo, D. E., & Yang, K. (2017). A Further Strategic Move to Sustainability-A Case Study on IKEA. ... IKEA's Supply Chain: Growth on Sustainability ...

IKEA supply chain is a global supply chain, steps in production, transportation, and distribution can occur in different countries. Also, the creation of the New Crown epi-demic has put significant pressure on the global supply chain [14]. According to statis-tics, 94% of Fortune 1000 companies faced disruptions in their supply chains as a result

The case study research is mainly concerned with implementation of supply chain strategy through discussion of IKEA's strategic business purpose. Thus, the case intends to analyze supply chain management and competitive strategy applicable to

The paper is a case study for the different types of risks faced by IKEA as the company started its operations in China. How the risks were mitigated, avoided or accepted has been discussed. Download Free PDF. View PDF. Centralised supply chain planning at IKEA Supply Chain Management: An International Journal.

IKEA has cut its packaging usage by 50% over the last few years, and continues its journey into more sustainable packaging by exploring new plant-based materials. IKEA is a brand that needs no introduction. With more than € 41 billion in total retail sales, the Swedish brand is dominant in the furniture market on a global scale.

This video goes over IKEA's story and how it has become the largest furniture retailer in the world over a short period of time. It discusses the various Su...

The case examines the supply chain management practices of IKEA, Sweden based furniture retailer. IKEA, the world's leading retailer by sales had its presence across the globe. The company focused on providing its customers affordable yet stylish and functional furniture. It made efforts to eliminate several activities that added to the final cost of the furniture but could be avoided.

This Case describes IKEA's growth, including the importance of a sourcing strategy based on its close relationships with suppliers in developing countries. D...

4. IKEA as a case study. This case study offers insight into SSCM practices in action. IKEA was chosen for the case study, amongst many, for three primary reasons. IKEA is a global firm with ...

Moore quickly a State of Emergency while the rescue efforts continued. Effect on Supply Chain. The collapse of the Key Bridge, a critical part of Baltimore's infrastructure, will have major implications on the supply chain.The Port of Baltimore is the biggest handler of US imports and exports of cars and light trucks, handling 847,158 autos and light trucks in 2023.