Upmetrics AI Assistant: Simplifying Business Planning through AI-Powered Insights. Learn How

Entrepreneurs & Small Business

Accelerators & Incubators

Business Consultants & Advisors

Educators & Business Schools

Students & Scholars

AI Business Plan Generator

Financial Forecasting

AI Assistance

Ai pitch deck generator

Strategic Planning

See How Upmetrics Works →

- Sample Plans

- WHY UPMETRICS?

Customers Success Stories

Business Plan Course

Small Business Tools

Strategic Canvas Templates

E-books, Guides & More

- Sample Business Plans

- Retail, Consumers & E-commerce

Furniture Manufacturing Business Plan

After getting started with upmetrics , you can copy this sample business plan into your business plan and modify the required information and download your furniture manufacturing business plan pdf and doc file. It’s the fastest and easiest way to start writing your business plan.

Download a sample furniture manufacturing business plan

Need help writing your business plan from scratch? Here you go; download our free furniture manufacturing business plan pdf to start.

It’s a modern business plan template specifically designed for your furniture manufacturing business. Use the example business plan as a guide for writing your own.

Related Posts

Hardware Shop Business Plan

Handicraft Business Plan

Design Cover Page for Business Plan

Essential components of a business plan

About the Author

Upmetrics Team

Upmetrics is the #1 business planning software that helps entrepreneurs and business owners create investment-ready business plans using AI. We regularly share business planning insights on our blog. Check out the Upmetrics blog for such interesting reads. Read more

Plan your business in the shortest time possible

No Risk – Cancel at Any Time – 15 Day Money Back Guarantee

Popular Templates

Create a great Business Plan with great price.

- 400+ Business plan templates & examples

- AI Assistance & step by step guidance

- 4.8 Star rating on Trustpilot

Streamline your business planning process with Upmetrics .

AI Generated Business Plan

Here is your Startup Idea

You can use this idea to start your own business. You can also use it to pitch to investors.

Modular Furniture Manufacturing

How to write a business plan for a furniture manufacturer?

Creating a business plan for a furniture manufacturer is an essential process for any entrepreneur. It serves as a roadmap that outlines the necessary steps to be taken to start or grow the business, the resources required, and the anticipated financial outcomes. It should be crafted with method and confidence.

This guide is designed to provide you with the tools and knowledge necessary for creating a furniture manufacturer business plan, covering why it is so important both when starting up and running an established business, what should be included in your plan, how it should be structured, what tools should be used to save time and avoid errors, and other helpful tips.

We have a lot to cover, so let's get to it!

In this guide:

Why write a business plan for a furniture manufacturer?

- What information is needed to create a business plan for a furniture manufacturer?

- What goes in the financial forecast for a furniture manufacturer?

- What goes in the written part of a furniture manufacturer business plan?

- What tool can I use to write my furniture manufacturer business plan?

Being clear on the scope and goals of the document will make it easier to understand its structure and content. So before diving into the actual content of the plan, let's have a quick look at the main reasons why you would want to write a furniture manufacturer business plan in the first place.

To have a clear roadmap to grow the business

It's rarely business as usual for small businesses. The economy follows cycles where years of growth are followed by recessions, and the business environment is always changing with new technologies, new regulations, new competitors, and new consumer behaviours appearing all the time...

In this context, running a business without a clear roadmap is like driving blindfolded: it's dangerous at best. That's why writing a business plan for a furniture manufacturer is essential to create successful and sustainable businesses.

To write an effective business plan, you will need to take stock of where you are (if you are already in business) and where you want the business to go in the next three to five years.

Once you know where you want your furniture manufacturer to be, you'll have to identify:

- what resources (human, equipment, and capital) are needed to get there,

- at what pace the business needs to progress to get there in time,

- and what risks you'll face along the way.

Going through this process regularly is beneficial, both for startups and existing companies, as it helps make informed decisions about how best to allocate resources to ensure the long-term success of the business.

To maintain visibility on future cash flows

Businesses can go for years without making a profit, but they go bust as soon as they run out of cash. That's why "cash is king", and maintaining visibility on your furniture manufacturer's future cash flows is critical.

How do I do that? That's simple: you need an up-to-date financial forecast.

The good news is that your furniture manufacturer business plan already contains a financial forecast (more on that later in this guide), so all you have to do is to keep it up-to-date.

To do this, you need to regularly compare the actual financial performance of your business to what was planned in your financial forecast, and adjust the forecast based on the current trajectory of your business.

Monitoring your furniture manufacturer's financial health will enable you to identify potential financial problems (such as an unexpected cash shortfall) early and to put in place corrective measures. It will also allow you to detect and capitalize on potential growth opportunities (higher demand from a given segment of customers for example).

To secure financing

Whether you are a startup or an existing business, writing a detailed furniture manufacturer business plan is essential when seeking financing from banks or investors.

This makes sense given what we've just seen: financiers want to ensure you have a clear roadmap and visibility on your future cash flows.

Banks will use the information included in the plan to assess your borrowing capacity (how much debt your business can support) and your ability to repay the loan before deciding whether they will extend credit to your business and on what terms.

Similarly, investors will review your plan carefully to assess if their investment can generate an attractive return on investment.

To do so, they will be looking for evidence that your furniture manufacturer has the potential for healthy growth, profitability, and cash flow generation over time.

Now that you understand why it is important to create a business plan for a furniture manufacturer, let's take a look at what information is needed to create one.

Need a convincing business plan?

The Business Plan Shop makes it easy to create a financial forecast to assess the potential profitability of your projects, and write a business plan that’ll wow investors.

Information needed to create a business plan for a furniture manufacturer

You need the right data in order to project sales, investments and costs accurately in the financial forecast of your furniture manufacturer business plan.

Below, we'll cover three key pieces of information you should gather before drafting your business plan.

Carrying out market research for a furniture manufacturer

Before you begin writing your business plan for a furniture manufacturer, conducting market research is a critical step in ensuring precise and realistic financial projections.

Market research grants you valuable insights into your target customer base, competitors, pricing strategies, and other crucial factors that can impact the success of your business.

In the course of this research, you may stumble upon trends that could impact your furniture manufacturer.

Your market research may reveal that customers may be looking for furniture that is more sustainable and eco-friendly. Additionally, it could point to a trend of customers wanting furniture that is customizable in terms of size and color.

Such market trends play a pivotal role in revenue forecasting, as they provide essential data regarding potential customers' spending habits and preferences.

By integrating these findings into your financial projections, you can provide investors with more accurate information, enabling them to make well-informed decisions about investing in your furniture manufacturer.

Developing the sales and marketing plan for a furniture manufacturer

As you embark on creating your furniture manufacturer business plan, it is crucial to budget sales and marketing expenses beforehand.

A well-defined sales and marketing plan should include precise projections of the actions required to acquire and retain customers. It will also outline the necessary workforce to execute these initiatives and the budget required for promotions, advertising, and other marketing efforts.

This approach ensures that the appropriate amount of resources is allocated to these activities, aligning with the sales and growth objectives outlined in your business plan.

The staffing and equipment needs of a furniture manufacturer

Whether you are at the beginning stages of your furniture manufacturer or expanding its horizons, having a clear plan for recruitment and capital expenditures (investment in equipment and real estate) is vital to ensure your business's success.

To achieve this, both the recruitment and investment plans must align coherently with the projected timing and level of growth in your forecast. It is essential to secure appropriate funding for these plans.

A furniture manufacturer may incur costs for staff salaries, benefits, and training. They may need to provide tools and safety equipment for their employees, such as protective eyewear, gloves, and earplugs. They may also need to purchase various types of machinery for production, such as saws, routers, and drills. Additionally, they may need to purchase materials such as wood, metal, and fabric to make their furniture.

To create a financial forecast that accurately represents your business's outlook, remember to factor in other day-to-day operating expenses.

Now that you have all the necessary information, it's time to dive in and start creating your business plan and developing the financial forecast for your furniture manufacturer.

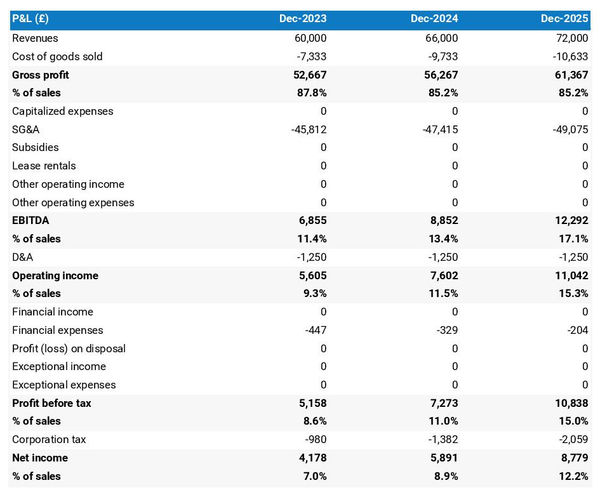

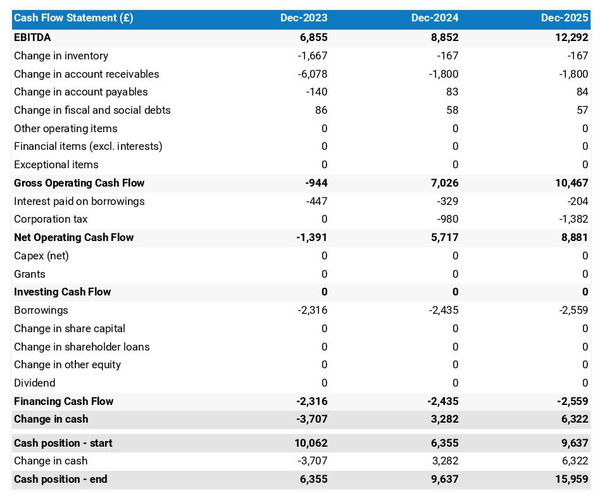

What goes into your furniture manufacturer's financial forecast?

The financial forecast of your furniture manufacturer's business plan will enable you to assess the growth, profitability, funding requirements, and cash generation potential of your business in the coming years.

The four key outputs of a financial forecast for a furniture manufacturer are:

- The profit and loss (P&L) statement ,

- The projected balance sheet ,

- The cash flow forecast ,

- And the sources and uses table .

Let's look at each of these in a bit more detail.

The projected P&L statement

The projected P&L statement for a furniture manufacturer shows how much revenue and profit your business is expected to make in the future.

A healthy furniture manufacturer's P&L statement should show:

- Sales growing at (minimum) or above (better) inflation

- Stable (minimum) or expanding (better) profit margins

- A healthy level of net profitability

This will of course depend on the stage of your business: numbers for a startup will look different than for an established furniture manufacturer.

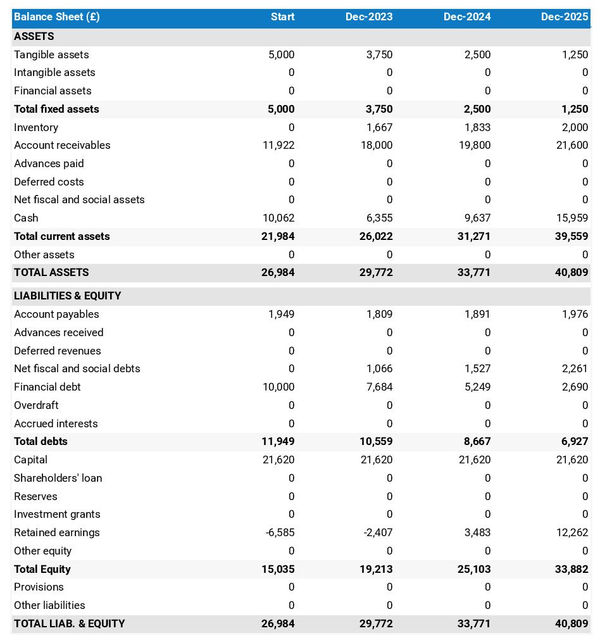

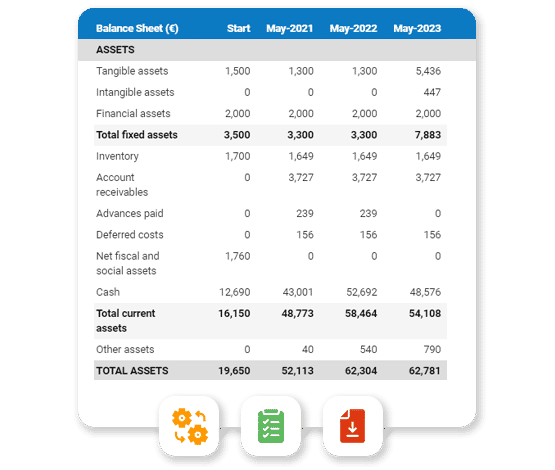

The projected balance sheet of your furniture manufacturer

Your furniture manufacturer's forecasted balance sheet enables the reader of your plan to assess your financial structure, working capital, and investment policy.

It is composed of three types of elements: assets, liabilities and equity:

- Assets: represent what the business owns and uses to produce cash flows. It includes resources such as cash, equipment, and accounts receivable (money owed by clients).

- Liabilities: represent funds advanced to the business by lenders and other creditors. It includes items such as accounts payable (money owed to suppliers), taxes due and loans.

- Equity: is the combination of what has been invested by the business owners and the cumulative profits and losses generated by the business to date (which are called retained earnings). Equity is a proxy for the value of the owner's stake in the business.

Your furniture manufacturer's balance sheet will usually be analyzed in conjunction with the other financial statements included in your forecast.

Two key points of focus will be:

- Your furniture manufacturer's liquidity: does your business have sufficient cash and short-term assets to pay what it owes over the next 12 months?

- And its solvency: does your business have the capacity to repay its debt over the medium-term?

The cash flow forecast

As we've seen earlier in this guide, monitoring future cash flows is the key to success and the only way of ensuring that your furniture manufacturer has enough cash to operate.

As you can expect showing future cash flows is the main role of the cash flow forecast in your furniture manufacturer business plan.

It is best practice to organise the cash flow statement by nature in order to show the cash impact of the following areas:

- Cash flow generated from operations: the operating cash flow shows how much cash is generated or consumed by the business's commercial activities

- Cash flow from investing activities: the investing cash flow shows how much cash is being invested in capital expenditure (equipment, real estate, etc.) either to maintain the business's equipment or to expand its capabilities

- Cash flow from financing activities: the financing cash flow shows how much cash is raised or distributed to financiers

Looking at the cash flow forecast helps you to make sure that your business has enough cash to keep running, and can help you anticipate potential cash shortfalls.

Your furniture manufacturer business plan will normally include both yearly and monthly cash flow forecasts so that the readers can view the impact of seasonality on your business cash position and generation.

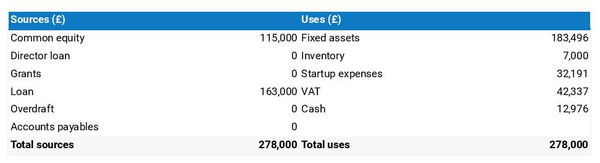

The initial financing plan

The initial financing plan, also known as a sources and uses table, is a valuable resource to have in your business plan when starting your furniture manufacturer as it reveals the origins of the money needed to establish the business (sources) and how it will be allocated (uses).

Having this table helps show what costs are involved in setting up your furniture manufacturer, how risks are shared between founders, investors and lenders, and what the starting cash position will be. This cash position needs to be sufficient to sustain operations until the business reaches a break-even point.

Now that you have a clear understanding of what goes into the financial forecast of your furniture manufacturer business plan, let's shift our focus to the written part of the plan.

Need inspiration for your business plan?

The Business Plan Shop has dozens of business plan templates that you can use to get a clear idea of what a complete business plan looks like.

The written part of a furniture manufacturer business plan

The written part of a furniture manufacturer business plan is composed of 7 main sections:

- The executive summary

- The presentation of the company

- The products and services

- The market analysis

- The strategy

- The operations

- The financial plan

Throughout these sections, you will seek to provide the reader with the details and context needed for them to form a view on whether or not your business plan is achievable and your forecast a realistic possibility.

Let's go through the content of each section in more detail!

1. The executive summary

The executive summary, the first section of your furniture manufacturer's business plan, serves as an inviting snapshot of your entire plan, leaving readers eager to know more about your business.

To compose an effective executive summary, start with a concise introduction of your business, covering its name, concept, location, history, and unique aspects. Share insights about the services or products you intend to offer and your target customer base.

Subsequently, provide an overview of your furniture manufacturer's addressable market, highlighting current trends and potential growth opportunities.

Then, present a summary of critical financial figures, such as projected revenues, profits, and cash flows.

You should then include a summary of your key financial figures such as projected revenues, profits, and cash flows.

Lastly, address any funding needs in the "ask" section of your executive summary.

2. The presentation of the company

In your furniture manufacturer business plan, the second section should focus on the structure and ownership, location, and management team of your company.

In the structure and ownership part, you'll provide an overview of the business's legal structure, details about the owners, and their respective investments and ownership shares. This clarity is crucial, especially if you're seeking financing, as it helps the reader understand which legal entity will receive the funds and who controls the business.

Moving on to the location part, you'll offer an overview of the company's premises and their surroundings. Explain why this particular location is of interest, highlighting factors like catchment area, accessibility, and nearby amenities.

When describing the location of your furniture manufacturer, you could emphasize its proximity to major transportation hubs, as well as its access to a wide range of possible suppliers. You might also point out that the region has a diverse workforce and a strong commitment to economic growth. Furthermore, the area could offer a competitive tax and regulatory environment, making it attractive to investors. Finally, you may want to mention the potential to expand if needed, as the region is growing and has a vibrant infrastructure.

Finally, you should introduce your management team. Describe each member's role, background, and experience.

Don't forget to emphasize any past successes achieved by the management team and how long they've been working together. Demonstrating their track record and teamwork will help potential lenders or investors gain confidence in their leadership and ability to execute the business plan.

3. The products and services section

The products and services section of your business plan should include a detailed description of the offerings that your company provides to its customers.

For example, your furniture manufacturer could offer custom furniture design services to customers who are looking for a unique piece of furniture for their home or office. Additionally, they could offer a variety of finish options so that customers can customize the look of their furniture to their own personal preference. Finally, they could also offer upholstery services so that customers can customize the fabric and/or other materials used for their furniture. These services would be beneficial to customers as it would allow them to customize their furniture to their own personal taste.

When drafting this section, you should be precise about the categories of products or services you sell, the types of customers you are targeting and how customers can buy them.

4. The market analysis

When you present your market analysis in your furniture manufacturer business plan, it's crucial to include detailed information about customers' demographics and segmentation, target market, competition, barriers to entry, and any relevant regulations.

The main objective of this section is to help the reader understand the size and attractiveness of the market while demonstrating your solid understanding of the industry.

Begin with the demographics and segmentation subsection, providing an overview of the addressable market for your furniture manufacturer, the key trends in the marketplace, and introducing different customer segments along with their preferences in terms of purchasing habits and budgets.

Next, focus on your target market, zooming in on the specific customer segments your furniture manufacturer aims to serve and explaining how your products and services fulfil their distinct needs.

For example, your target market might include young professionals. This segment likely has money to spend and is looking for quality furniture to fill their new home. They want something stylish that will last for years and will be worth the investment.

Then proceed to the competition subsection, where you introduce your main competitors and highlight what sets you apart from them.

Finally, conclude your market analysis with an overview of the key regulations applicable to your furniture manufacturer.

5. The strategy section

When crafting the strategy section of your business plan for your furniture manufacturer, it's important to cover several key aspects, including your competitive edge, pricing strategy, sales & marketing plan, milestones, and risks and mitigants.

In the competitive edge subsection, clearly explain what sets your company apart from competitors. This is particularly critical if you're a startup, as you'll be trying to establish your presence in the marketplace among entrenched players.

The pricing strategy subsection should demonstrate how you aim to maintain profitability while offering competitive prices to your customers.

For the sales & marketing plan, outline how you plan to reach and acquire new customers, as well as retain existing ones through loyalty programs or special offers.

In the milestones subsection, detail what your company has achieved thus far and outline your primary objectives for the coming years by including specific dates for expected progress. This ensures everyone involved has clear expectations.

Lastly, in the risks and mitigants subsection, list the main risks that could potentially impact the execution of your plan. Explain the measures you've taken to minimize these risks. This is vital for investors or lenders to feel confident in supporting your venture - try to proactively address any objection they might have.

Your furniture manufacturer faces a variety of risks. They may have difficulty finding suppliers of the raw materials they need to create their furniture. If suppliers are limited, the manufacturer could be stuck with high prices for materials and be unable to turn a profit. Additionally, the manufacturer might face the risk of competition from other furniture manufacturers with similar products. If the market is flooded with similar products, the manufacturer may have difficulty selling their furniture.

6. The operations section

The operations of your furniture manufacturer must be presented in detail in your business plan.

Begin by addressing your staff, specifying the main roles and your recruitment plan to support the anticipated growth. Outline the qualifications and experience needed for each role and discuss your recruitment strategies, which may involve using job boards, referrals, or headhunters.

Next, clearly state your furniture manufacturer's operating hours, allowing the reader to gauge the adequacy of your staffing levels. Additionally, mention any considerations for varying opening times during peak seasons and your approach to handling customer queries outside regular operating hours.

The key assets and intellectual property (IP) required to run your business should also be highlighted. If you rely on licenses, trademarks, physical structures like equipment or property, or lease agreements, ensure they are well-documented in this section.

You may have key assets such as the physical space of your factory - the machinery, tools, technology, and employees who power it - as well as valuable Intellectual Property (IP) such as proprietary production processes and furniture designs. Your IP may include any patented designs, unique techniques, or trade secrets that could give your furniture company an edge over competitors.

Finally, provide a comprehensive list of suppliers you intend to collaborate with, along with a breakdown of their services and main commercial terms, such as price, payment terms, break clauses and contract duration. Investors often seek insight into the reasons behind your supplier choices, which may include a preference for higher-quality products or established relationships from past ventures.

7. The presentation of the financial plan

The financial plan section is where we will include the financial forecast we talked about earlier in this guide.

Now that you have a clear idea of the content of a furniture manufacturer business plan, let's look at some of the tools you can use to create yours.

What tool should I use to write my furniture manufacturer's business plan?

There are two main ways of creating your furniture manufacturer business plan:

- Using specialized business planning software,

- Hiring a business plan writer.

Using an online business plan software for your furniture manufacturer's business plan

Using online business planning software is the most efficient and modern way to create a furniture manufacturer business plan.

There are several advantages to using specialized software:

- You can easily create your financial forecast by letting the software take care of the financial calculations for you without errors

- You are guided through the writing process by detailed instructions and examples for each part of the plan

- You can access a library of dozens of complete business plan samples and templates for inspiration

- You get a professional business plan, formatted and ready to be sent to your bank or investors

- You can easily track your actual financial performance against your financial forecast

- You can create scenarios to stress test your forecast's main assumptions

- You can easily update your forecast as time goes by to maintain visibility on future cash flows

- You have a friendly support team on standby to assist you when you are stuck

If you're interested in using this type of solution, you can try The Business Plan Shop for free by signing up here .

Need a solid financial forecast?

The Business Plan Shop does the maths for you. Simply enter your revenues, costs and investments. Click save and our online tool builds a three-way forecast for you instantly.

Hiring a business plan writer to write your furniture manufacturer's business plan

Outsourcing your furniture manufacturer business plan to a business plan writer can also be a viable option.

These writers possess valuable experience in crafting business plans and creating accurate financial forecasts. Additionally, enlisting their services can save you precious time, enabling you to concentrate on the day-to-day operations of your business.

It's important to be mindful, though, that hiring business plan writers comes with a cost. You'll be paying not just for their time but also for the software they use, and their profit margin.

Based on experience, a complete business plan usually requires a budget of at least £1.5k ($2.0k) excluding tax, and more if revisions are needed after initial meetings with lenders or investors - changes often arise following these discussions.

When seeking investment, be cautious about spending too much on consulting fees. Investors prefer their funds to contribute directly to business growth. Thus, the amount you spend on business plan writing services and other consulting services should be negligible compared to the amount you raise.

Another aspect to consider is that while you'll receive the output of the business plan, you usually won't own the actual document. It will be saved in the consultant's business plan software, which will make updating the plan challenging without retaining the consultant on a retainer.

Given these factors, it's essential to carefully weigh the pros and cons of outsourcing your furniture manufacturer business plan to a business plan writer and decide what best suits your business's unique needs.

Why not create your furniture manufacturer's business plan using Word or Excel?

Using Microsoft Excel and Word (or their Google, Apple, or open-source equivalents) to write a furniture manufacturer business plan is a terrible idea.

For starters, creating an accurate and error-free financial forecast on Excel (or any spreadsheet) is very technical and requires both a strong grasp of accounting principles and solid skills in financial modelling.

As a result, it is unlikely anyone will trust your numbers unless - like us at The Business Plan Shop - you hold a degree in finance and accounting and have significant financial modelling experience in your past.

The second reason is that it is inefficient. Building forecasts on spreadsheets was the only option in the 1990s and early 2000s, nowadays technology has advanced and software can do it much faster and much more accurately.

And with the rise of AI, software is also becoming smarter at helping us detect mistakes in our forecasts and helping us analyse the numbers to make better decisions.

Also, using software makes it easy to compare actuals vs. forecasts and maintain our forecasts up to date to maintain visibility on future cash flows - as we discussed earlier in this guide - whereas this is a pain to do with a spreadsheet.

That's for the forecast, but what about the written part of my furniture manufacturer business plan?

This part is less error-prone, but here also software brings tremendous gains in productivity:

- Word processors don't include instructions and examples for each part of your business plan

- Word processors don't update your numbers automatically when they change in your forecast

- Word processors don't handle the formatting for you

Overall, while Word or Excel may be viable options for creating a furniture manufacturer business plan for some entrepreneurs, it is by far not the best or most efficient solution.

- Using business plan software is a modern and cost-effective way of writing and maintaining business plans.

- A business plan is not a one-shot exercise as maintaining it current is the only way to keep visibility on your future cash flows.

- A business plan has 2 main parts: a financial forecast outlining the funding requirements of your furniture manufacturer and the expected growth, profits and cash flows for the next 3 to 5 years; and a written part which gives the reader the information needed to decide if they believe the forecast is achievable.

We hope that this in-depth guide met your expectations and that you now have a clear understanding of how to write your furniture manufacturer business plan. Do not hesitate to contact our friendly team if you have questions additional questions we haven't addressed here.

Also on The Business Plan Shop

- How to write a business plan to secure a bank loan?

- Key steps to write a business plan?

- Top mistakes to avoid in your business plan

Do you know entrepreneurs interested in starting or growing a furniture manufacturer? Share this article with them!

Founder & CEO at The Business Plan Shop Ltd

Guillaume Le Brouster is a seasoned entrepreneur and financier.

Guillaume has been an entrepreneur for more than a decade and has first-hand experience of starting, running, and growing a successful business.

Prior to being a business owner, Guillaume worked in investment banking and private equity, where he spent most of his time creating complex financial forecasts, writing business plans, and analysing financial statements to make financing and investment decisions.

Guillaume holds a Master's Degree in Finance from ESCP Business School and a Bachelor of Science in Business & Management from Paris Dauphine University.

Create a convincing business plan

Assess the profitability of your business idea and create a persuasive business plan to pitch to investors

500,000+ entrepreneurs have already tried our solution - why not join them?

Not ready to try our on-line tool ? Learn more about our solution here

Need some inspiration for your business plan?

Subscribe to The Business Plan Shop and gain access to our business plan template library.

Need a professional business plan? Discover our solution

Write your business plan with ease!

It's easy to create a professional business plan with The Business Plan Shop

Want to find out more before you try? Learn more about our solution here

10 Steps to Launching a Profitable Furniture Manufacturing Business

Related blogs.

- The Surprising Profitability of Furniture Manufacturing: Why You Need to Invest in This Thriving Industry

- Unleash Your Inner Entrepreneur: How to Start a Furniture Manufacturing Business from Scratch

- 7 Essential Metrics for Successful Furniture Manufacturing: Track Your Progress Now!

Starting a furniture manufacturing business is one of the smartest investments you can make. Furniture is an essential part of our daily lives, providing comfort and style to our homes and offices. In the last decade the furniture market has grown at an astonishing rate, with the global industry predicted to be worth $622.27 billion by 2024.

There's no denying this is an industry worth getting into, but starting a business is never easy. To help you launch your own furniture manufacturing business, here are 10 steps to consider - a comprehensive checklist to make your journey smoother, and ensure success.

When launching any business venture, it's important to have a clear vision for what you want to achieve. Furniture manufacturing isn't just about creating tables and chairs - it's about creating beautiful, high-quality products, and providing excellent customer service.

1. Envision Goal

Setting up a furniture manufacturing business is an ambitious proposition but can be lucrative, especially when planned and implemented successfully. The first step towards success is to clearly define the ultimate goal of the business. Ask yourself: ‘What do I want to achieve with this business?’

Have an honest and realistic assessment of what you are trying to achieve. Do you aim to turn a hobby into a full-time job? Are you seeking to supplement family income or become a successful manufacturer of furniture for export to international markets?

Whatever your goals, setting realistic targets and having a documented plan of action will help ensure your venture is successful. Set both short-term and long-term goals to ensure that you are able to keep track of your progress and make adjustments accordingly.

Tips & Tricks

- Be realistic - not everyone will become a major exporter of furniture

- Write down your goals, both short term and long term

- Review your progress regularly and adjust as needed

Having a clear and achievable goal will also make it easier to identify the equipment and space you require. To reduce costs, consider reworking old furniture or renting equipment instead of buying straight away.

Research Furniture Market & Industry

Before you launch your business, it is important that you do ample research on the furniture industry and the furniture market. You need to understand who your potential customers are, what kind of furniture they are looking for, and the competitive landscape of the furniture industry. This will help you to develop an effective business strategy.

Start by researching the furniture industry and its specific markets. What are the main trends in the furniture industry? Are there any emerging furniture technologies that could give you a competitive advantage? What is the competitive landscape like? Who are the major players and how do you differentiate yourself from them?

Next, look into the potential customer base for your business. Who is likely to buy your furniture? Is it residential or commercial customers? Are there any particular demographics that might be interested in your furniture? You should also research the furniture market to understand what people are looking for and what kind of prices they are willing to pay. This will help you to come up with product offerings and pricing strategies.

Finally, research your competition. What are the major players in the furniture manufacturing industry? What are their strategies and how do they differentiate themselves from the rest? Understanding your competitors can be a key factor in finding success in the furniture manufacturing industry.

- Take time to do comprehensive research into the furniture industry and its markets.

- Think about the potential customer base for your business and what they might be looking for.

- Research the competitive landscape to understand the strategies of the major players and how you can differentiate yourself from them.

3. Identify Competitors & Opportunities

Opening a new Furniture Manufacturing Business is often an exciting endeavour, but it’s important to understand the market you are entering. Your success will, in part, be determined by the number and the strength of competitors in your area or around the world. Knowing who the major players are in the industry and the opportunities for standing out in the crowd will help you plan for success.

Do Your Research

When you’re launching a new business, it’s essential to know the lay of the land in your industry. Researching your competitors is a great place to start. You should look at their designs, prices, customer service features, and delivery capabilities so you can get a better understanding of what the industry standard is and then devise a plan to fill the gaps and exceed customer expectations.

Getting an understanding of who makes up your competition is important, but completing a SWOT (strengths, weaknesses, opportunities, threats) analysis can help you develop a strategy that will set you apart from the competition. With an excellent strategy, you can go beyond competing on price and have a unique value proposition and identity.

- Research the competition. Know who you’re up against in the industry. Learn from their products, prices, customer service features, and delivery capabilities.

- Do a SWOT analysis. Identify your own strengths, weaknesses, opportunities, and threats and create a strategy to set you apart from the competition.

- Focus on a unique value proposition. Going beyond competing on price gives you a higher chance to succeed and stand out.

- Make sure you are up-to-date on the latest trends and technology in the industry. Stay ahead of the pack.

- Reach out to the niche markets and create personalized experiences for them.

- Make sure your website has a great user experience and is SEO optimized.

4. Develop Business Plan & Financial Model

A business plan serves as your roadmap for success and is often the difference between success and failure. It will give prospective investors the details they need to make informed decisions and will help shape the overall vision and success of the business. To get started, one must evaluate the following: obtain a plan for the business, identify the type of business you want to set up, do market research, create a budget and financial model, and put together a team.

- Obtain a Plan for the Business: Determine what the business needs and the goals of the business. Consider the type of furniture you want to manufacture, who your target customers are, and what markets the business will serve. Compile a list of all equipment, personnel, and other resources needed to make the business successful.

- Identify the Type of Business: Consider the type of furniture manufacturing business you want to set up. Determine if it will be a sole proprietorship, a limited liability company, a partnership, or a corporation. Consider filing fees, taxes, and other legal requirements for starting a business in the chosen jurisdiction.

- Do Market Research: Establish a customer base and define the scope of the market. Include a competitive analysis, distribution channels, and pricing strategy. Get to know the local industry, including the production costs, pricing trends, and expected market growth.

- Create a Budget and Financial Model: Create a budget for the business to cover the cost of goods, materials, labor, equipment, legal fees, and other ongoing expenses. Develop a financial model that factored in overheads, operating costs, and management costs. Estimate potential profit and quantify potential risk.

- Put Together a Team: Develop a team focused on the skills and abilities necessary for launching and managing the furniture manufacturing business. Hire staff, advisors, and consultants as needed. Establish their roles and create a timeline for each task to be accomplished.

Tips & Tricks for Developing a Business Plan & Financial Model

- Research: Conduct thorough research on the local market conditions and the industry. Understand the competition, pricing, and other aspects of the industry.

- Set Goals: Establish clear goals for the business and create tangible plans to reach these goals.

- Get Expert Advice: Consult financial advisors, lawyers, and other experienced people to help create a realistic business plan that will help the business find success.

5. Source Funding & Financial Resources

Establishing a furniture manufacturing business will require substantial financial investment. This is a necessary part of building a successful and profitable business. Identifying and accessing sources of funding can be a crucial factor in helping you succeed.

There are a variety of potential sources of funding for entrepreneurs who wish to start their own furniture manufacturing business. These include:

- Business loans – Business loans are a popular choice for entrepreneurs who need to borrow money in order to start or grow their business. There are a variety of loans available, from sba loan to venture capital, to helping you obtain the capital you need for your furniture manufacturing business.

- Investors – Investors can provide a great source of funding for entrepreneurs. They provide money in exchange for either an equity share in the business or a share of company profits. This can be a great way to supplement traditional financing sources, such as bank loans, and can help you get your furniture manufacturing business off the ground.

- Grants –There are also grants available for entrepreneurs who want to start a furniture manufacturing business. These grants can be local, state, or even federal in origin. Doing the proper research and applying for grants can often be a relatively pain-free way of getting money for your business.

- Personal savings – Not to be underestimated is the power of personal savings. While it may not always be possible to rely solely on your own savings to finance a business, it can be an invaluable source of seed money or capital when starting a furniture manufacturing business.

The right source of funding for your furniture manufacturing business will depend on your individual situation and goals. Speak with an accountant, financial planner, and/or small business specialist to determine which sources of funding may be the best fit for you.

- Be sure to research and understand the terms and conditions of any funding sources you are considering, to ensure that you are getting the best option.

- Be prepared with professional business plans and financial projections to help secure investors.

- Your local Small Business Association (SBA) can provide valuable resources and guidance when seeking funding for your business.

6. Secure Necessary Permits & Licenses

Starting a furniture manufacturing business requires getting the necessary permits and licenses from local, state, and federal governments. It is important to check with the local government in the municipality or area where the business will be established to find out what permits and licenses are needed. Additionally, it is important to check with the federal government to find out what permits or licenses may be needed.

Certain types of activities or locations may require other permits, in addition to the permits and licenses mentioned above. One important area to explore is the need for zoning permits; many furniture manufacturing businesses require a special zoning permit from the local government.

Furthermore, businesses must also register with the state and make sure their employees have all necessary certifications. It is important to check with the state’s employment department to learn about the requirements necessary for hiring and employing individuals.

- Be sure to research and understand all the local, state, and federal regulations that will apply to your business before starting your furniture business.

- If possible, consult with an attorney to understand the specialty permits needed in your area.

- Make sure all employees are employed legally by obtaining and adhering to all necessary state violations.

7. Location & Setup

Location is an important factor in starting a furniture manufacturing business. The area chosen should be near a good source of raw materials, suppliers, customers, and trained labour. Choose an industrial area that allows for a quick and easy flow of raw materials and finished products.

In order to ensure an efficient operation, furniture manufacturing businesses must identify their key equipment and other operational needs. This involves the selection, purchase, and installation of essential furniture machinery, such as saws, routers, grinders, conveyor systems, and so on. Relevant investments such as dust collectors, construction equipment, and special tools should also be considered.

In addition, other features to consider during setup include flooring, storage, waste disposal, electrical wiring, ventilation, and safety. Making sure to create an ergonomic workspace, with adjustable workstations and ample storage is key for worker health, comfort, and productivity. It is also important to take into consideration environmental regulations when setting up the space.

- Do research into local and state regulations to ensure compliance with safety, energy and tax codes.

- Take advantage of tax benefits for purchasing certain equipment.

- Invest in a good dust-collection system.

8. Hire & Train Employees

To open your furniture manufacturing business you will need to start hiring employees. Prior to hiring, you should decide on the number of staff you need, the job requirements, and the desired job titles. Often, you may need to hire people to fill management roles, such as operations managers and production managers.

You will also need to hire experienced personnel to operate the equipment, as well as to assist in order fulfillment and product shipping.

It is important to make sure you have the right hiring policies in place to make sure you are selecting qualified personnel. When interviewing potential employees, it is important to make sure they meet the qualifications and job requirements.

Once you have identified the right personnel for the job, you should provide formal training. This is important because it will ensure your employees understand your business process and operations. It is also important to ensure they understand the various regulations and safety standards applicable to your business.

- Make sure to conduct background checks on your staff before making hiring decisions.

- Provide formal training to ensure your employees understand your business process & operations.

- Be aware of the applicable regulations and safety standards for furniture manufacturing businesses.

9. Promote & Market

Marketing is an essential aspect of a successful business, especially when introducing a brand-new product onto the market. It is necessary for keeping campaigns on track to ensure greater reach and visibility.

Here are some of the best steps for effectively promoting a furniture manufacturing business:

- Develop a sound marketing strategy. Lay out all the different marketing techniques (e.g. social media, traditional media, public relations, etc), decide on how much resources will be allocated for each one and determine the expected outcomes for each marketing exercise

- Develop a press kit that includes the company’s mission, company’s history, listings of products and services and all the contact information. This kit can be used to help potential investors better understand the business.

- Invest in a website. Make sure the website is user-friendly and well designed, showcasing the most important information about the product. It should also have a feature for customers to easily place orders for the products.

- Create an engaging social media presence. Update the account regularly with beautiful product pictures and latest promotions. Participating in social media conversations and promoting the business through social media channels can also be an effective way to reach potential customers.

- Find ways to connect with potential customers. Join relevant online forums, some of the biggest online chairmakers groups and contact influencers and bloggers to assess if they can help to promote the products.

- Develop relationships with other retailers. Exploring the possibility of working with other retailers in the area to stock the products.

- Create content (e.g videos, blog posts) related to furniture making, using storytelling to attract more potential customers.

- Attend trade shows and other industry events to network with other professionals in the furniture industry.

- Send out newsletters regularly or email customers in the mailing list about the latest products and promotions.

10. Measure & Adapt

It is essential to track and measure the progress of your furniture manufacturing business over time to understand how it fares with the initial goals. It also helps to redirect resources and activities to be in line with the stated objectives.

Set Targets and Monitor Progress

The goals should be quantifiable and be realistic to succeed. Monitor the progress made in production, customer satisfaction, revenue and profitability regularly and align the goals with the actual results to re-evaluate the previous and current efforts for long-term success.

Analyze Performance

Measure the financial results of the furniture business against the projected numbers. Analyze the deviation in the performance by comparing the actual data to the set targets. Gauge the performance of each product in a systematic manner.

Make Periodic Adjustments

Find out the areas where the performance is below expectations. Make the adjustments for enhancing efficiency in those areas. Focus on proper implementation of the plans and management of resources. Introduce new strategies, if necessary.

- Evaluate existing operations and introduce changes for boosting the speed of implementation.

- Prioritize the projects and understand the achievement path of each.

- Invest in useful data analysis tools to gain insights into the performance and improve the long-term success.

By following the 10 steps outlined in this checklist, you will be well on your way to starting your own successful furniture manufacturing business. From having a clear vision of your goal to securing necessary permits and licenses, to recruiting and training staff, and finally, to marketing and measuring results, these steps will ensure your venture is successful every step of the way.

With the global furniture market predicted to be worth $622.27 billion by 2024, now is the perfect time to get into the furniture manufacturing business and create beautiful, high-quality products that customers will love.

5-Year Excel

MAC & PC Compatible

Immediate Download

Related Articles

The surprising truth about profitability in the appliance store industry: a deep dive into the numbers, why investing in an alcohol treatment center is more profitable than you think, counting the profits: a closer look at the profitability of accounting agencies, the art of boosting profits in your a la carte restaurant: a comprehensive guide, airbnb: unpacking the profitability of one of the world's most successful companies., the untold story of how car washes are making a fortune: discover the profit potential today, pedaling to profit: unveiling the lucrative world of bicycle couriers, thirsty for success discover the untapped profit potential of running a beer bar, the beauty within profits: discovering the lucrative world of beauty salons, unlocking the profit potential: how to make your beach hotel more profitable, leave a comment.

Your email address will not be published. Required fields are marked *

Please note, comments must be approved before they are published

Start a Furniture Manufacturer: Your Ultimate Guide

Starting your own furniture manufacturer can be a daunting task. But with the right guidance, it can be an immensely rewarding experience. In this ultimate guide, we’ll show you everything you need to know to get started on your journey to becoming a furniture manufacturer. From securing the proper licenses and permits, to finding the perfect location for your business, we’ll cover all the bases. So if you’re ready to take the first step towards starting your own furniture manufacturing company, read on!

Table of Contents

What is a furniture manufacturing business, how do i find customers for my furniture manufacturing business.

A furniture manufacturing business, also known as a furniture maker or furniture company, designs and constructs pieces of furniture for individuals and businesses. Sometimes these businesses specialize in a particular type of furniture such as office desks or beds, while others may offer a range of styles and materials. They often also offer customization options for their customers. The production process typically starts with the creation of plans or designs, followed by the cutting and shaping of wood or other materials. Next, the pieces are assembled and finished, with upholstery added if necessary.

Finally, the finished product is ready to be delivered to the customer. A furniture manufacturing business can sell directly to customers through their own retail store or website, or they can work with retailers and wholesalers to distribute their products. Overall, these businesses play a crucial role in bringing comfort and functionality to homes and workplaces across the world.

Why would I want to start a Furniture Manufacturing business?

A lot of people think that furniture manufacturing is a dying industry. After all, isn’t everything being made overseas these days? While it’s true that a lot of furniture is now being made in China and other countries, there is still a very strong demand for high quality, hand-crafted furniture here in the United States. In fact, now is a great time to consider a career in furniture manufacturing!

Here are three reasons why you should consider a career in furniture manufacturing:

There is a strong demand for American-made furniture.

As mentioned above, there is still a very strong demand for American-made furniture. People are willing to pay more for furniture that is made in the USA because they know that it is going to be of higher quality. If you start your own furniture manufacturing business, you will be able to tap into this growing market.

You can be your own boss.

One of the best things about starting your own business is that you get to be your own boss. When you work for someone else, you have to follow their rules and do things their way. But when you’re the boss, you get to make all of the decisions! If you’re tired of working for someone else and want to be in control of your own destiny, then starting a furniture manufacturing business may be the perfect option for you.

You can make a good living.

If you start your own successful furniture manufacturing business, you can make a very good living. In fact, many people who own their own businesses are able to live quite comfortably. If you’re looking for a way to improve your lifestyle and make more money, then starting your own business may be the right move for you.

Starting your own furniture manufacturing business can be a great way to improve your lifestyle and make more money. There is a strong demand for American-made furniture, and if you’re tired of working for someone else, being your own boss can be very appealing! If you’re considering starting your own business, furniture manufacturing is definitely worth considering!

How do I start a Furniture Manufacturer?

Are you interested in starting your own furniture manufacturing company? This can be a great way to get involved in the design and production of furniture, while also having the opportunity to manage your own business. Before you get started, there are a few things you need to know about how to start a furniture manufacturer. Here’s what you need to know to get started.

What are the initial steps in starting a furniture manufacturer business

If you’re interested in starting a furniture manufacturing business, the first step is to develop a clear idea of what type of furniture you want to produce. Are you creating custom-made designs, or will you be producing standard pieces such as chairs and tables? Once you have a strong concept in place, it’s important to secure funding for your business and acquire the necessary equipment and materials. You may also need to secure licenses or permits, depending on the regulations in your area.

Next, it’s time to start building relationships with potential clients and suppliers. Research the market and look for opportunities to showcase your products at trade shows or through online platforms. As with any business, it’s important to have a solid marketing strategy in place as well as a budget for ongoing expenses such as rent, employees, and inventory.

Starting a furniture manufacturing business requires careful planning and dedication, but the end result can be a successful and fulfilling venture.

How much money do I need to start this type of business

Starting a furniture manufacturer business can be a significant financial investment, but the exact amount depends on various factors.

For example, will you have your own manufacturing facility or contract with an outside manufacturer? Will you hire employees or work alone? Will you purchase raw materials or source them through partnerships?

Additionally, consider startup costs like permits and licenses, equipment and machinery, branding and marketing expenses, and a financial cushion for any unforeseen expenses. After carefully identifying expenses and potential sources of funding, you can create a realistic budget for starting your furniture manufacturer business. Remember to factor in ongoing operating costs as well and plan for long-term financial sustainability.

With careful planning, you can determine the amount of money needed to launch your business successfully.

What licenses and permits will I need to operate legally

If you’re thinking of starting a furniture manufacturing business, there are several licenses and permits that you’ll need in order to operate legally.

First, you’ll want to check with your state or local government to see if you need a business license or permit. This may also involve registering your business name and getting a Federal Tax ID number. In addition, depending on the type of furniture you plan on making, you may also need industry-specific licenses or permits, such as woodworking permits or upholstery certifications.

It’s important to research and obtain all required licenses and permits before beginning operation, as failure to do so could result in fines or even the shutdown of your business. As always, it’s a good idea to consult with an attorney or accountant for guidance on the specific requirements for your area and industry.

How do I find the right employees for my new company

When it comes to finding the right employees for your new furniture manufacturer business, it’s important to clarify the specific skills and experience that you are looking for. Are you seeking out individuals with design expertise or a background in woodworking? Or do you need employees who have experience managing supply chains and logistics?

Clearly define your needs and then use a combination of job postings, recruitment agencies, networking events, and referrals from trusted colleagues to find qualified candidates. Additionally, consider offering internships or apprenticeships to up-and-coming professionals or recent graduates in order to provide them with hands-on learning opportunities while filling skill gaps in your team. By defining your needs and using a proactive approach to finding employees, you can set yourself up for success as you establish your furniture manufacturer business.

What type of marketing strategy should I use to get my furniture brand out there

As a new furniture manufacturer, it can be difficult to know how to best market your brand and stand out in a saturated industry. One effective approach may be to focus on a niche market or specific style that sets you apart from other furniture manufacturers. This could involve targeting a specific demographic, such as eco-conscious millennials, or honing in on a particular design aesthetic, such as modern minimalism or Scandinavian craftsmanship.

Once you identify your niche, tailor your branding and advertising efforts to speak directly to that target market. Additionally, consider utilizing influencer marketing by collaborating with popular social media users who align with your brand and have an engaged following in your niche market. By targeting a specific niche and leveraging influencers, you can effectively elevate your furniture brand in the competitive industry.

How often should I review my business plan and make necessary changes

When starting a new business, it’s important to have a clear plan in place including goals, budgets, and strategies. However, this plan shouldn’t be set in stone. As your business grows and changes, your plan should also adapt to the current circumstances.

How often you review and revise your business plan will depend on the specific needs of your company and industry. That said, as a general rule of thumb, it’s a good idea to review and update your plan at least once a year. This helps to ensure that you are staying on track with your goals and making any necessary changes or adjustments along the way. It’s also important to revisit your plan whenever there are major shifts or developments in your industry or marketplace.

Staying flexible and always thinking about the future can help keep your business thriving for years to come.

How much does it cost to start a Furniture Manufacturing business?

So, you want to start a furniture business. Congratulations! The furniture industry is a great place to be. But before you get too far ahead of yourself, you need to take a step back and answer one very important question: how much does it cost to start a furniture business?

The answer, unfortunately, is not as straightforward as you might hope. The costs of starting a furniture business can vary greatly depending on the size and scope of your operation. Are you planning on opening a small, local store? Or are you aiming for something bigger, like an online presence or a franchise? The answer to this question will have a big impact on your start-up costs.

In this section, we’ll take a look at some of the most important factors that will affect how much it costs to start your very own furniture business. By the time you’re finished reading, you’ll have a better idea of what you need to get started and how much it’s going to cost you. Let’s get started!

Cost of Inventory

The first thing you need to consider is the cost of inventory. When starting a furniture business, you need to have enough inventory on hand to meet customer demand. This can be a substantial investment, particularly if you’re planning on producing high-end pieces or selling in bulk. To get an idea of how much inventory will cost you, take a look at similar businesses in your area and see what they charge for their products. You can also contact wholesalers and manufacturers directly to get pricing information.

Real Estate

Another important factor is the cost of rent or mortgage payments for your store or warehouse space. If you’re planning on opening a brick-and-mortar store, then this will be one of your largest expenses. Make sure to factor in the cost of utilities and other associated expenses when budgeting for your store space.

Marketing Your Furniture Manufacturing Business

Another significant expense is the cost of marketing and advertising your new business. You’ll need to find ways to reach your target market and let them know about your products and services. This can be done through traditional methods like print ads and radio spots, or through more modern methods like digital marketing and social media campaigns. Whichever route you choose, make sure you factor in the costs of designing and implementing your marketing strategy when estimating your start-up costs.

Finally, don’t forget about miscellaneous expenses like office supplies, employee uniforms, and so forth. These may seem like small items, but they can add up quickly if you’re not careful. Make sure to include them in your budget so that you don’t end up with any unpleasant surprises down the road.

These are just some of the things that will affect how much it costs to start your own furniture business. As you can see, there are a lot of factors to consider—but don’t let that discourage you! With careful planning and execution, you can successfully launch your dream furniture business without breaking the bank.

Starting a furniture manufacturing business can be a great way to create pieces that are truly unique and one-of-a-kind. But once you’ve started your business, how do you find customers? Read on for some tips on how to market your furniture manufacturing business.

Evaluate your target market

Before launching a marketing campaign for a furniture manufacturer, it is important to evaluate the target market. Who are the current customers buying the furniture? Are they mostly individuals, or businesses? What age range do they fall into? Which socioeconomic group do they belong to?

Gathering this information can help identify potential new customer segments worth targeting. For example, if the current customer base is primarily young professionals, targeting empty-nesters or recently married couples could bring in new business.

Conducting market research and gathering demographic data can also reveal potential niches that have not yet been tapped into, such as eco-conscious individuals who may be interested in sustainable furniture options. Taking the time to evaluate and expand upon the target market can lead to increased sales and growth for a furniture manufacturer.

Research your competition

When running a furniture manufacturer business, it’s important to have an understanding of your competition. By researching the other furniture companies in your industry, you can identify gaps in their offerings and use that information to target new customers.

For example, if a competitor only offers traditional style furniture, you could focus on modern designs and market yourself to a younger demographic. It’s also helpful to assess the pricing strategies of your competition and determine where you can offer more competitive rates without sacrificing profit margins. By conducting thorough research on the competition, you can develop a targeted approach for attracting new customers to your furniture business.

Develop a marketing strategy

When developing a marketing strategy for a furniture manufacturer, it’s important to consider the target market. Who are the ideal customers for this particular brand and style of furniture? Once the target market has been identified, a variety of tactics can be used to reach them.

For example, advertising in publications or sponsoring events that cater to this demographic can help get the brand in front of potential customers. It may also be helpful to partner with design professionals, such as interior designers or architects, who can recommend the furniture to their clients. In addition, having a strong presence on social media and building an enticing website can attract potential customers from across the country or even around the world.

However, it’s important to constantly analyze and reassess these strategies to ensure they are effectively attracting new customers for the furniture manufacturer business.

Implement your marketing plan

When it comes to finding new customers for your furniture manufacturer business, implementing a strong marketing plan is key. First, consider your target market and what they are looking for in a piece of furniture. Are they more interested in function or style?

Once you have settled on a target audience, create compelling marketing materials that showcase your products and speak directly to your desired customer base. Social media can also be a valuable tool for reaching potential customers.

Regularly update your page with new pieces and special promotions, engaging with followers to build relationships and drive sales. Don’t forget about traditional forms of advertising as well, such as newspaper or magazine ads or even signage at local stores or events. By developing a comprehensive marketing plan and actively implementing it, you will be well on your way to finding new customers for your furniture business.

About Jeremy Reis

Jeremy Reis is a serial entrepreneur from the Franklin, Tennessee area. Jeremy is the founder of multiple businesses and is the VP of Marketing for CRISTA Ministries. Jeremy has his MBA with a focus in Entrepreneurship from The Ohio State University.

The Important Stuff

Privacy Policy

Featured Businesses

Big & Tall Shop

Coffee Shop

Daycare Center

© ExploreStartups 2022

Privacy Policy | Terms Of Service | Site Map

Email: [email protected]

Phone: (402) 289-0309

Understanding the Modular Furniture Manufacturing Process

When you think “modular furniture” you most likely think of companies like Amazon or Ikea – cheap, put-together-yourself type of furniture that doesn’t usually last long. At Modular Furniture Group we’re different, our modular furniture manufacturing process is like no other.

Our unique modular furniture manufacturing process ensures that you, as a customer, get the most out of your new piece of furniture. This means our items are sturdy and built to last but are also made with your specifications in mind. They combine the ease of being able to change things up to create new working environments with all natural woods and designs that stay around for the long haul – just like furniture should be.

Over the years, we’ve mastered the ability to do this and our process is unmatched. But, what is it exactly? In this article, we’ll outline the 3 steps we take to provide the best quality and service when it comes to the modular furniture manufacturing process.

The look and feel of your space matters. Whether you are a business, bank, school, or medical facility we take the impact of your environment seriously. During the design process, we work with your contractor to ensure all custom wood workspaces meet your space, electrical, and mechanical requirements.

Some key elements we use to make this happen are:

- Utilizing the state-of-art technology of Wood working machinery

- Using precision machined parts ensuring accurate modular assembly

- Building with accuracy and on time delivery

- Pre-engineering component parts for rapid turn around, custom finished to each project’s specifications

- Implementing “old school” craftsmanship with Computer Aided Manufacturing

Fabrication

A great design needs to still be made well and built to last as your business or facility changes. To make this happen, we pair old woodworking techniques with modern technology to get the best results. Based on your specifications, the custom wood workstations, desks, or cabinets are then preassembled in our factory and shipped to your destination. They come premeasured and ready for set up as soon as they get there – no need for any wait time!

We make sure you have the best quality by:

Installation

Our tagline is “renovate in a weekend”, and we mean!

Once your custom designed furniture is built and shipped we then reconnect with your contractor to coordinate the installation so when the time comes, the process is quick and seamless. Contractors are involved in the installation process to ensure the entire space is functional and put together correctly. Plus, this turn key installation means that your business doesn’t have to close – you can keep operating!

To ensure speed and efficiency we:

- Assign a project manager that orchestrates the entire installation

- Provide delivery to the job site

- Coordinate electrical, data, security, and computer equipment personnel

- Have on site tooling abilities for renovation adjustments

After the installation is complete, our service team works to make sure you are satisfied with the look, feel, and functionality of your new furniture. We promise quality customer service through each step of the process. Our service team will assist you with all warranties that assure that any problems with our product, hardware, workmanship, or finishes will be quickly remedied.

Want to put this process into action? Contact us today to see how Modular Furniture Group can transform your space for the better!

Furniture Manufacturing Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Arts & Craft Sector

Are you about starting a furniture manufacturing company ? If YES, here’s a complete sample furniture manufacturing business plan template & feasibility report you can use for FREE to raise money.

The furniture manufacturing industry is indeed a lucrative one. However, it is such that requires plenty of capital to start. This type of business needs loads of manpower as well as capital to run. This is essentially because it requires that furniture in produced and you will agree with me that this will include lots of processes. From sourcing for the raw materials to preparing the materials and what have you.

A Sample Furniture Manufacturing Business Plan Template

1. industry overview.

It is an established fact that furniture is a major part of our lives cum facilities; there is hardly any facility that you will come across that you won’t find a piece of furniture in it. This goes to show that the furniture manufacturing industry is indeed an important sector of the economy of any country.

Businesses in this industry mainly manufacture or make household (living room, dining room and bedroom furniture, upholstered, coffee tables, sofa tables, end tables, sofas, love seats, chairs, bookshelves, ottomans, display cabinets, consoles and TV stands and otherwise), outdoor and office furniture (Desks and home office goods, lamps, recliners, rugs and outdoor furniture make up the rest of sales).

The Furniture Manufacturing industry is indeed a major sector of the economy of the united states of America which generates a whopping sum of well over billion annually from more than 3,533furniture manufacturing companies scattered all around the United States of America. The industry is responsible for the employment of well over 105,640 people.

Experts project the furniture manufacturing industry to grow at a 2.0 percent annual rate. The establishment in this industry that has a dominant market share in the United States of America are; Ashley Furniture Industries, Inc., Herman Miller, HNI Corporation and Steel Case.

Research carried out by IBISWORLD clearly stated that proximity to downstream markets is an important competitive factor in this industry, since it enables furniture manufacturers to increase the speed of delivery and reduce transportation costs.

The regions in the United States that accounts for the largest number of furniture manufacturing companies also have the largest populations. With 25.8 percent of the industry establishments and more than a quarter of the US population, the Southeast region of the United States houses the largest number of industry facilities.

Little wonder this region also accounts for the highest number of furniture wholesalers and retailers, making it an ideal location for household furniture manufacturers that want to be in close proximity to downstream buyers.

Over and above, the furniture manufacturing industry is a profitable industry and it is open to any aspiring entrepreneur to come in and establish his or her business; you can chose to start on a small scale in small furniture making workshop or you can chose to start on a large scale with a standard furniture making workshop and several outlets in key cities through the United States of America and Canada.

2. Executive Summary