Lean Manufacturing Tools

Lean manufacturing tools, techniques and philosophy | lean and related business improvement ideas.

5S Training Presentations

5s pptx and 5s pdf downloads.

If you want to learn all about 5S then the following 5S presentations in ppt (PowerPoint) format and PDF format are available to you for free download. Please note that these 5S Training presentation files are protected by copyright and are to be downloaded for your own personal use only.

- Any commercial use of these 5S presentations and the content therein is prohibited without prior permission. Requests for permission to use can be made through the contact page of http://leanmanufacturingtools.org/contact-page/

- These presentations are for personal use only and cannot be reproduced or circulated by anyone other than www.leanmanufacturingtools.org

- Content may be quoted or reproduced for private and educational assignments as long as a proper citation is given referring to leanmanufacturingtools.org

- The information within these presentations and website are for information purposes only and any action taken is at your own risk.

These lean manufacturing training presentations are organized so that you can tackle the ideas behind 5S one step at a time, for your own education or even to train others within your own organization. Breaking them up into bite sized chunks allows you to learn or teach 5S in manageable and understandable sections even if your available time is limited.

These presentations can be use in conjunction with the following pages here;

Running your own 5S program

How to approach 5S training

Run your own 5S training course in house

5S Training PowerPoint (pptx) Presentations;

Basic introduction to 5s presentations;.

What is 5S – Learn what is 5S.

Benefits of 5S – Learn the benefits of implementing 5S within your organization.

Presentations Detailing Each 5S Stage;

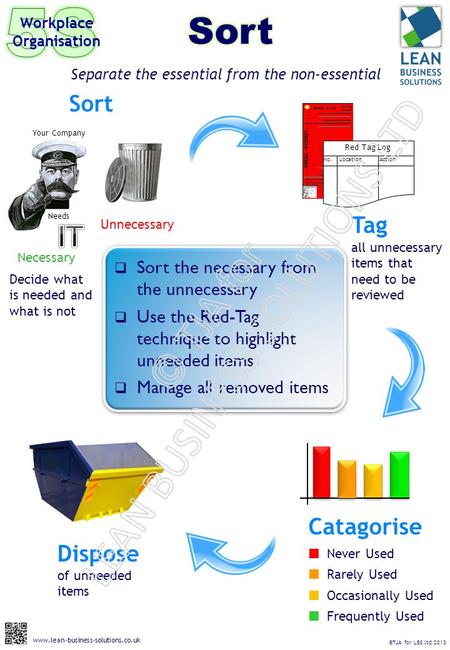

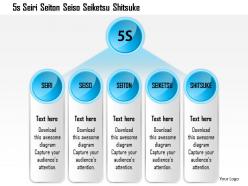

5S Seiri Sort – The first stage of implementing 5S.

5S Seiton Set in Order – The second stage of implementing 5S

5S Seiso Shine – The third stage of implementing 5S

5S Seiketsu Standardize – The forth stage of implementing 5S

5S Shitsuke Sustain – The fifth and final stage of 5S implementation

Lean 6S ppt Training Presentation;

6S – How does 6S differ from 5S and why?

Presentations Supporting Your 5S Training;

5S Red Tag – Learn how to use 5S Red Tags

Runners Repeaters Strangers – Learn how to apply RRS techniques when implementing 5S

Presentation Detailing How to Plan and Conduct Your 5S Implementation;

5S Program Implementation – Step by step guide to implementing 5S within your operations.

5S Training Exercise Presentation;

Training Exercise – 5S Paper exercise; a quick and simple training exercise designed for 5S which will demonstrate the simplicity and effectiveness of 5S.

5S Training PDF Files for Download;

All of the above 5S presentations are also available as 5S PDF files for download;

What is 5S Presentation

Benefits of 5S

5S Seiri or Sort – First stage of 5S

5S Seiton or Set In Order – Second stage of 5S

5S Seiso or Shine – Third stage of 5S

5S Seiketsu or Standardize – Forth stage of 5S

5S Shitsuke or Sustain – Final stage of 5S

5S Runners Repeaters and Strangers

Implementing 5S Program

5S Training Exercise

Should you require a personalized or editable version of these 5S PowerPoint presentations or 5S PDF files just contact the author through the contact page here; Leanmanufacturingtools.org contact page .

Suggestions for improvements or additions to the above 5S training presentations are welcomed.

Related posts:

- Lean Training, Coaching, and Presentations

- Free Lean Presentations

- 5S Training

Post navigation

13 comments for “ 5s training presentations ”.

i want fully details of 5s

Hi K.P. Feel free to download any of the presentations and PDF files here to provide you with all of the info that you need on 5S.

PLEASE BRIEF ON 5S / 6S , LATEST VERSION. 6 SIGMA.

let me know more about it

5’S means house keeping in our Indian language . each and every letters are starting from “S” letters .so,called 1s,2s 3s,4s&5s . on japan language India language 1) seiri -short out 2)seiton -set in order 3) seiso -shine 4)seiketshu -standardization 5)sitsuke -sustain short out -1)material segregated require /un require.if, unwanted material will be put red tag and remove from our working area 2)if,required material then will be put yellow tag .3)if,not required but,well material then will be through to red zone area . Set in Order – required material will be keep by rack /cup board /shelves etc 3)shine identified material clean daily /weekly/yearly 4)standardization this 1s,2s,3s will be keep regularly. 5)sustain this work will be make habit.

How can I download the course?

Samer, Just click on the links to download each of the 5S presentations.

hi Earley i would like develop on these 5 s principles using my domain knowledge in the Oil and Gas upstream sector and would like to conduct workshops to our fraternity please confirm if you have any objection regards Damodaran M

I would like to use this training for our maintenance department at Westrock Solvay ny.

I have “before” pictures ready and will have “after” pictures as well.

Would you like to see our ,ppt when complete?

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

CAPTCHA Code *

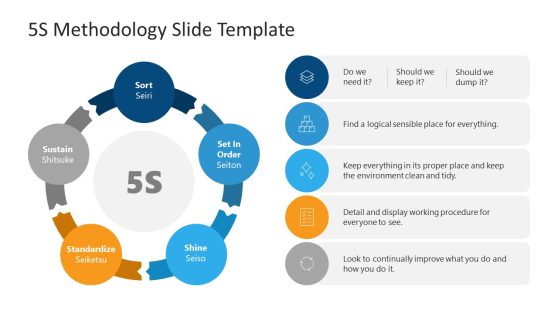

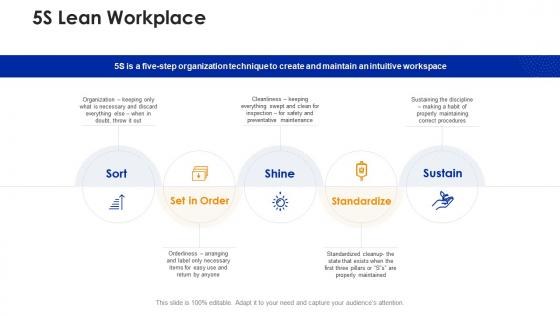

What Is the 5S Methodology?

The 5S methodology is best summarized by the philosophy, “a place for everything and everything in its place.”

You may have heard of “KonMari,” a home organization system invented by Marie Kondo. The KonMari method transforms cluttered homes into tidy and simplified living spaces. The 5S principles are similar to KonMari. However, saying that 5S is just about tidying is like saying successful manufacturing is just about speed - there is much more depth. So, let’s explore the true intent and meaning of 5S.

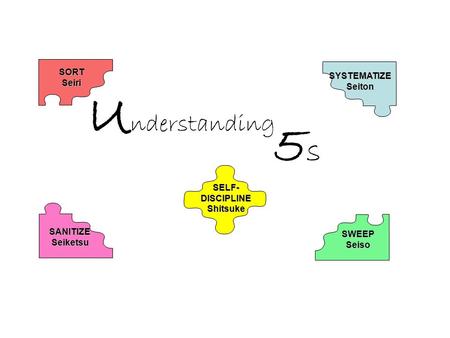

5S Japanese Words

5S originated as 5 Japanese words:

5S Meaning in English

In English, these 5S meanings are:

- Sort (Seiri): Eliminate that which is not needed.

- Straighten (Seiton): Organize what remains after sorting.

- Shine (Seisou): Clean and inspect the work area.

- Standardize (Seiketsu): Write standards for 5S.

- Sustain (Shitsuke): Consistently apply the 5S standards.

At their core, these 5S activities build the discipline needed for substantial and continuous improvement by creating (and sustaining) efficient and effective work areas.

Why Is 5S Important in Manufacturing?

While 5S was first developed in the context of the automotive industry, it is now widely considered an essential step for any lean manufacturing program, regardless of industry.

Embedding 5S as part of daily tasks within your company means much more than improved organization, sustained cleaning routines, and efficient activity flows. By using the 5S methodology, operators are encouraged to improve their overall work environment and reduce muda or waste .

Adherence to 5S standards is considered the foundation of Total Productive Maintenance (TPM) and an integral part of the Toyota Production System (TPS) . 5S also creates a stable platform from which Kaizen activities can be launched.

The bottom line - 5S is a low-investment, high-impact lean manufacturing tool that is predicated on people. It engages operators in “owning” their workspace and helps to instill a culture of quality, productivity, and improvement.

What Are the 5 Benefits of a 5S System?

The key benefits of a 5S system include:

- Creating space within your facility by removing unnecessary tools and equipment

- Reducing waste from unnecessary motion by organizing the workspace

- Reducing downtime and improving quality by consistently maintaining equipment

- Engaging operators by granting them more responsibility for their work environment

- Creating a safer work environment by ensuring it is clean and well-maintained

Now that you have a better understanding of why 5S is important and how it can benefit your manufacturing operations, let’s learn more about each of the 5S steps.

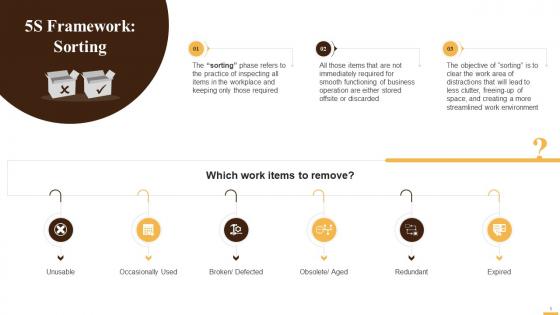

Sort (Seiri)

What is sort.

The Sort step separates items in your workspace that you know you need from items that you do not or may not need. Move the latter to a “red tag” holding area.

Why Do You Need Sort?

Sort enables you to have a more productive workspace by removing unneeded clutter (and eliminating distractions). It also is a first step towards opening up space that can be used for other things.

How Do You Implement Sort?

Separate necessary items (e.g., tools, parts, and materials) from unnecessary items. We recommend sorting items into four categories:

- Items needed in this work area. These are items you know that you regularly use in the context of this work area and thus will stay in this work area.

- Items needed in another work area. These are typically misplaced items. If an item is used in another work area, “sort” it into that area by delivering it to the team member responsible for that work area.

- Items you may need. For items you are unsure about, use the 5S “red tag” system. Mark such items with red tags, which at a minimum, should include the name of who tagged the item, why it is thought to no longer be needed, a proposed review date, and the name of the manager who must approve of disposal. Move the item to a red tag holding area, which should be organized by review month to make it easy to manage the area.

- Items you do not need. These are items that you are 100% confident are not needed. They should be immediately discarded, recycled, or donated, or sold if in good condition.

What Are Some Examples of Sort?

- Remove waste (or muda) from your workspace.

- Discard broken or old parts using 5S red tags.

- Responsibly recycle materials and papers.

- Separate everyday tools from special-case tools.

- Avoid overfilling your workspace with excess materials.

- Create an overflow area outside of the workspace for duplicate materials, tools, and parts.

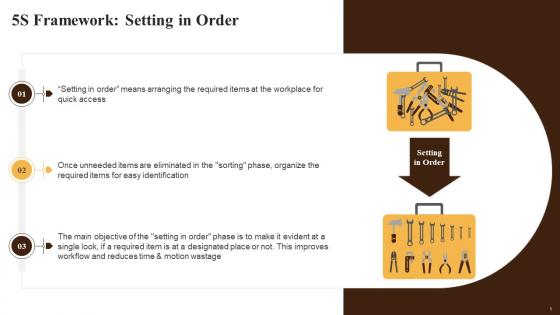

Straighten (Seiton)

What is straighten.

The Straighten step thoroughly organizes the items that remain after sorting, making frequently used items easily accessible and providing every item a clear and easy-to-find home.

Why Do You Need to Straighten?

Straighten enables every item to have a specific home where it can be easily found and to which it can be easily returned. It reduces the waste from excess motion, as items are placed in more ergonomic locations. It is also the second step on the path to opening up space that can be used strategically toward the goal of improving production.

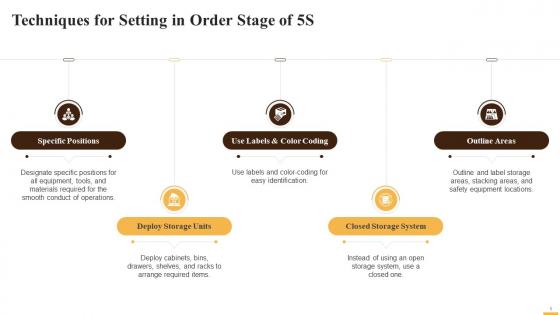

How Do You Implement Straighten?

After you’ve sorted items, it’s time to decide how you want to organize them. We recommend the following methodology:

- Provide easy access to frequently used items. The key to reducing waste from excess motion is to place frequently used items within easy reach.

- Group like items. Group the remaining items into logical categories and brainstorm the best way to organize and store each of these categories.

- Utilize visual designs. For each group, decide on the best way to make it clear when an item is missing or misplaced. A classic example is creating a shadow board for tools.

- Use containers. If it is appropriate for the type of item, consider organizing it within a container.

- Unleash the labeler. If an item is too big to put into a container, consider giving it a frame and putting a label on the item in addition to the frame.

- Be agile . Your initial straighten pass will likely deliver a significant improvement - but you are also likely to overlook some potential improvements. Plan a 5S team meeting with a focus on straightening at the one and two week points, and brainstorm further improvements as part of your initial implementation.

What Are Some Examples of Straighten?

- Give every item a distinct “home.”

- Use color as a way of organizing and creating meaning.

- Integrate shadow boards and other visual indicators into the plant floor.

- Dedicate a surface or area entirely to shadow boxes and tool storage.

- Dedicate another surface or area entirely to working.

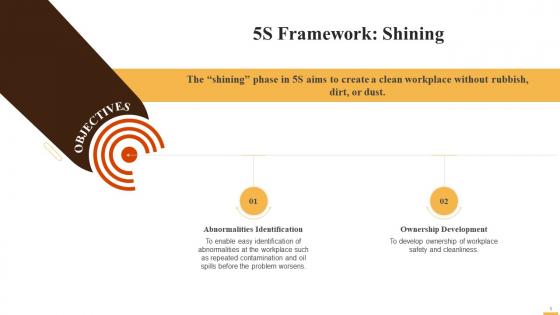

Shine (Seisou)

What is shine.

The Shine step elevates the work area by ensuring thoroughly cleaned and inspected tools, equipment, and other items. It also can include routine maintenance on equipment, which is one of the ways it flows directly into TPM .

Why Do You Need to Shine?

Shine creates a work environment that engages and empowers operators by giving them more responsibility and agency over their work area. It also helps them to identify problems before they interfere with production. For example, in a clean work environment, it is much easier to spot emerging issues such as fluid leaks, material spills, metal shavings from unexpected wear, hairline cracks in mechanisms, etc.

How Do You Implement Shine?

After you’ve straightened items, it’s time to elevate the work area by cleaning, inspecting, and in some cases, performing routine maintenance. We recommend the following:

- Grab the metaphorical spray bottle. Using appropriate cleaners and cleaning tools, make the work area sparkle. With every sweep, mop, brush, wipe, wash, and wax, strive to return your workspace to its former glory. Be Miyagi.

- Find the source. The guiding principle of this 5S step is “clean to understand”. If there are any signs of leaks, spills, or unexpected debris, strive to understand the source. It is likely an early warning of a future problem.

- Inspect. After cleaning each item, take a moment to look it over and examine its condition. Does it need updating, maintenance, or repair?

What Are Some Examples of Shine?

- Wipe down equipment.

- Examine the wear of your tools.

- Disassemble larger objects to inspect the state of their parts.

- Investigate a recurring unclean spot or mess.

- Make sure to follow proper cleaning procedures to prevent damage to equipment.

Standardize (Seiketsu)

What is standardize.

The Standardize step is a bridge between the first three 5S steps (Sort, Straighten, Shine) and the last step (Sustain). In this step, your goal is to capture best practices for 5S as standardized work for your team.

Why Do You Need to Standardize?

Standardize makes 5S repeatable. It transforms 5S from a one-off project to a reproducible set of activities.

How Do You Implement Standardize?

It’s time to make sure all your hard work continues to pay dividends into the future. Set expectations for the future with a documented 5S process. To do so, we recommend that you:

- Document in pairs. Have one team member walk through each 5S task as another team member documents it to ensure nothing important is missed.

- Capture the essence. We are huge proponents of simplicity (and agile ). Capture the essence of each task and no more. Otherwise, your documentation will be difficult to maintain.

- Prefer checklists. Checklists feel easy. Short checklists feel even easier. A great format is providing a name for each task that serves as a quick reminder and a more detailed description for training.

- Organize to simplify. Organize your checklists by role, by shift, and by frequency (daily, weekly, monthly). This will make the 5S process much less intimidating to your team.

What Are Some Examples of Standardize?

- Write down your 5S practices.

- Create “implementation” checklists and “audit” checklists.

- Create “kits” that contain the materials needed to perform a specific task.

- Use photos and other simple visuals as part of your training materials.

- Build a schedule for tasks.

Sustain (Shitsuke)

What is sustain.

The Sustain step ensures that 5S is applied on an ongoing basis. It transforms your standardized 5S processes into regularly completed tasks.

Why Do You Need to Sustain?

Iterative 5S processes lock in your gains and ensure further and continued progress.

How Do You Implement Sustain?

Once you’ve standardized, it’s time to continually act upon those standards. We recommend you:

- Create a schedule. Embed 5S practices as scheduled tasks (by role, shift, and frequency).

- Teach through demonstration. Instruct employees on how to conduct 5S tasks through demonstration and training. Showing employees what is expected of them will prepare them to conduct tasks on their own.

- Supervise to solo. After initial 5S training for employees, gently supervise while they continue to form habits. It is easy to make mistakes or fall off course, so patiently and helpfully offer corrections when needed.

- Adapt as necessary. When giving or receiving feedback on tasks, see where changes can be made to make the tasks easier and more efficient. Standardized work is intended to be living documentation.

What Are Some Examples of Sustain?

- Hold a demonstration meeting to explain complex or multi-step processes.

- Perform periodic check-ins after initial training.

- Teach employees to run 5S audits.

- Respond to mistakes with additional training.

- Encourage supervisors and operators to communicate openly and constructively to find ways to improve your 5S implementation.

- Set quarterly audit reminders for reviewing the red tag holding area.

The Bonus S of 5S

Now that you know how to implement each step in the 5S methodology and foster a culture of continuous improvement in your factory, you are ready to learn the bonus S: Safety!

5S is meant to help you improve productivity in your factory, but it is also meant to help create a safe, positive work environment for your team. While preventing workplace injuries is very important - also important is that 5S will make your plant a great place to work. Everyone enjoys a safe, clean, and logically laid out work environment, and it will motivate your employees, leading to better results on the plant floor.

How Does Each of the 5S Steps Contribute to Safety?

- Sort removes items from the plant floor, creating more space. Of course, this space can be used to hold new tools and equipment, but it can also be used to create larger aisles and more open spaces in the factory, removing tripping hazards. Even something as simple as decluttering drawers can prevent injuries (e.g., accidental encounters with a sharp object when rummaging for the tool you need).

- Straighten gives every item a logical home near the location where operators will use it. This prevents operators from rushing around looking for what they need, avoiding chaos on the plant floor that could cause safety hazards. For example, operators could slip, trip, or bump into one another if they have to constantly hurry around looking for tools.

- Shine cleans the workspace and maintains equipment. This prevents leaks or spills from leaving slick spots on the floor and ensures operators have functioning tools so they don’t have to dangerously jerry-rig solutions.

- Standardize makes clear to everyone what needs to be done and to whom each task belongs so tasks are completed on a regular basis. Confusion regarding ownership of responsibilities can cause important jobs to be missed. For example, equipment that is not consistently maintained will likely create safety concerns.

- Sustain ensures your initial 5S efforts are not in vain, keeping your staff happy and on top of any new safety concerns as they arise. One of the most dangerous things you can have in your factory is unmotivated employees who do not care about maintaining the condition of their workplace. Ensuring their efforts to implement a 5S program are recognized and sustained will provide continued motivation.

Overall, the 5S process is worth the initial organizational work for the rewards in safety, production improvement, and employee motivation.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.

5S Methodology

– 5S Methodology –

⇓ Introduction to 5S

⇓ What is 5S

⇓ Why Implement 5S

⇓ How to Implement 5S

⇓ Learn More About 5S

Introduction to 5S

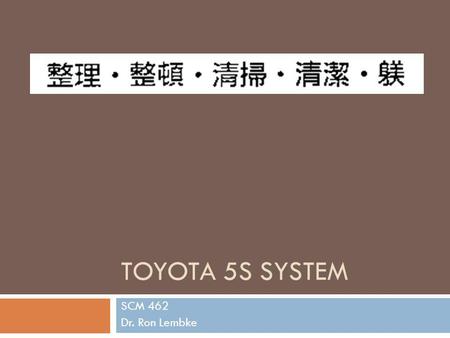

With the ever changing economic climate, many organizations are periodically adjusting their resources to align with business strategy. This often results in the need to achieve more work with fewer resources. In order to remain successful, businesses must become more efficient, reduce waste and thereby reduce cost. We must find ways to do what we are currently doing in less time and at a lower cost. One way we can accomplish this is through the use of 5S Principles. The 5S Principles are very effective at identifying and eliminating waste and increasing efficiency. There is a lot of information about 5S and how it came to be. The popular belief is that the Japanese invented the 5S Methodology because the letter “S” stands for five Japanese words, that when translated to roman script, start with the letter “S”. In actuality, the principles within 5S were being utilized decades before by Mr. Henry Ford. It has been reported that prior to 1920, Mr. Ford was using CANDO in his manufacturing processes. The acronym CANDO stands for Cleaning up, Arranging, Neatness, Discipline and Ongoing improvement. In the 1950s, representatives from Toyota visited the Ford facilities to be trained in automotive mass production methods. The Japanese later adapted the CANDO methods and applied them in their production facilities. Some commonly used words describing the steps in 5S are Sort, Set, Shine, Standardize and Sustain. Throughout different companies, various words are used that have similar meanings. No matter what specific words are used to identify the steps in 5S, the purpose remains the same: create a clean, organized and efficient work environment.

The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace. Improved visual controls are implemented as part of 5S to make any process non-conformance’s obvious and easily detectable. 5S is often one element of a larger Lean initiative and promotes continuous improvement. The 5S list is as follows:

- Seiri / Sort: Separating of the essential from the nonessential items

- Seiton / Straighten: Organizing the essential materials where everything has its place

- Seiso / Shine: Cleaning the work area

- Seiketsu / Standardize: Establishing a system to maintain and make 5S a habit

- Shitsuke / Sustain: Establishing a safe and sanitary work environment (Safety)

The 5S Principles are recognized in many industries as effective tools for improving workplace organization, reducing waste and increasing efficiency. Organizations should be careful to not allow the 5S Principles to become viewed as the whole of the company’s improvement efforts. Otherwise it could become the end goal of your company’s improvement process instead of a key part of a larger continuous improvement journey. The greatest benefit from using 5S is realized when it is part of a larger initiative and the entire organization has adopted its principles. 5S is more than a system; it is a business philosophy and should be integrated into the organization’s culture.

Why Implement 5S

There are many benefits to implementing the 5S Methods into a work area on the production line or in the business office. To not only survive but thrive in business today, cost must be controlled and waste must be avoided or eliminated. The 5S steps, when implemented properly, can identify and reduce many forms of waste in any process or workstation. An organized work area reduces excessive motion and wasted time looking for the right tool. The visual aspect of the 5S Methodology is also very effective. When everything has a place, it is easier to spot something missing or misplaced. A clean work area helps draw attention to possible problems or safety hazards. A clean floor helps spot any leaks or spills could indicate machine maintenance and prevent slips and falls. Furthermore, encouraging people to watch for and address problems can result in a positive change to an organizations culture. Therefore, the 5S Principles implemented as part of a larger Lean initiative or as a standalone tool can reduce waste, improve quality, promote safety and drive continuous improvement.

How to Implement 5S

The first step in 5S is sorting. During sorting the team should go through all items in the work area including any tools, supplies, bulk storage parts, etc. The 5S team leader should review and evaluate every item with the group. This will help to identify which items are essential for getting the job done effectively and efficiently. If the item is essential for everyday operations it should be tagged and cataloged. If the item is not essential, determine how often it is used in the performance of work in that area. If it is a bulk item, decide the proper amount to be kept in the area and move the remaining quantity to storage. Excess inventory is one form of waste and should be eliminated during the 5S activities.

Designate a place for all items that remain in the work area. Put all items in their designated location. An often referenced quote is “A place for everything and everything in its place”. During the straighten step, look for ways to reduce or eliminate waste. One form of waste in a process is unnecessary operator motion or movement. Therefore, frequently used tools and supplies should be stored in the immediate work area close to the operator. One effective method commonly used to avoid wasted time searching for the correct tool is constructing shadow boards for all essential tools. Items that are not used as often should be stored based on their frequency of use. All parts bins should be properly labeled. The label should include part number, part description, storage location and the recommended min / max quantities. A properly straightened work area allows the operator to quickly review and verify that they have everything they need to successfully perform their task at hand.

The next step is to clean everything in the area and remove any trash. To be effective we must keep the area and any related equipment clean. Dirty process equipment can actually increase the potential for process variability and lead to equipment failure. Lost time due to equipment failure is considered waste and non-value-added time. A dirty area can also contribute to safety issues that have the potential to cause a worker to be injured. Operators should clean their areas at the end of each shift. By doing this they will likely notice anything out of the ordinary such as oil or lubricant leaks, worn lift cables, burnt out bulbs, dirty sensors, etc. The purpose is to reduce waste and improve operator safety and efficiency.

Standardize

The fourth step has been called the most important step in the 5S Process. In this step we must develop the standards for the 5S system. They will be the standards by which the previous 5S steps are measured and maintained. In this step, work instructions, checklists, standard work and other documentation are developed. Without work instructions or standard work, operators tend to gradually just do things their own way instead of what was determined by the team. The use of visual management is very valuable in this phase. Color coding and standard colors for the surroundings are sometimes used. Photos of the area in the standard 5S configuration are often posted for easier identification of non-conformance’s. The operators are trained to detect non-conforming conditions and correct them immediately. Schedules should also be developed for regular maintenance activities in each area.

This step in the 5S Process can sometimes become the most challenging of all the five steps. Sustaining is the continuation of the Sort, Straighten, Shine and Standardize steps. It is the most important step in that it addresses the need to perform 5S on a consistent and systematic basis. During this step a standard audit system is usually developed and implemented. The goal of the sustain step is to ingrain the 5S process into the company culture. The company must strive to make 5S a way of life so the benefits gained through the exercise can be maintained. 5S is not a one-time exercise. Following the 5S Process must become a habit.

Some organizations have added an additional step and titled their process 5S + 1. The additional step being applied is safety. The goal of adding this step is to foster a culture that enhances safety by identifying any workplace hazards and removing them. In addition, tools and workstations are selected or designed with proper ergonomics in mind. The emphasis being that in each of the other 5S steps the motto is “Safety First”.

Many companies have implemented 5S into all areas of their business. The greatest benefits are usually realized when 5S is implemented as part of a larger Lean initiative within the organization. If implemented properly, 5S can help drive your company’s lean initiatives and be a powerful stimulus for developing a continuous improvement culture.

The 8 Forms of Waste:

As previously stated, 5S Principles are effective tools for reducing waste, improving quality, increasing efficiency, promoting safety and encouraging continuous improvement. When applying 5S Methods you should always remember the various forms which waste can take:

- Overproduction – Producing more product than required or producing parts faster than the downstream processes can utilize it. Strive to produce the proper amount at the proper time.

- Excessive Inventory – This can be a direct result of overproduction or it could be due to poor purchasing practices. Over purchasing supplies because we got a great deal sometimes is no deal at all. Excessive or unneeded inventory can propagate other forms of waste.

- Inappropriate or Non Value Added Processing – Waste is incurred through use of the wrong tool, performing needless operations or not using the most efficient processes or tools for the job. Beware of the phrase “Because we have always done it this way”. The right process and the correct tools can reduce waste in your process.

- Waiting – Time and resources are wasted when waiting on parts, supplies or information.

- Transportation – Excessive travel or movement of materials is waste. Proper planning and process layout can help reduce or eliminate excess transportation. The use of value stream mapping can help the team visualize exactly how much the material is traveling.

- Unnecessary Motion – Any movement or motion performed by the operator that does not add value is waste. During your 5S exercise examine the motions required to perform the task. Organize the workstation so all tools and supplies are easily located and within easy reach. In some cases, re-sequencing certain process steps can reduce excessive and redundant movement or motion by the operator. By reducing or eliminating the waste of excess motion you are also creating a more ergonomic workstation. Always consider safety first.

- Defects – This form of waste is one of the worst of all. Producing non-conforming parts or assemblies increases scrap, reduces process efficiency, wastes machine, process or assembly time and causes non-value added tool wear. Defects can also create additional waste in the form of wait time when the downstream operations run out of usable parts.

- Untapped Employee Creativity (potential) – Many companies are now realizing that their best asset is their employees. Companies must create an atmosphere where ideas are encouraged. Some of the most successful organizations have created a culture where employee’s ideas are really heard and evaluated. When their good ideas are implemented, the employee is recognized and rewarded. You never know where the next great idea is going to come from.

When you are implementing your 5S program or other lean tools watch out for the various forms of waste. Take action to eliminate waste in your processes. Get the team members involved and encourage them to provide ideas for improvements. When teams work together to recognize, address and eliminate waste and improve their workplace, they will take ownership of the process. They are more likely to spot any non-conformance’s in the future. The 5S Principles will gradually become a habit. Then you will begin to foster a culture of continuous improvement.

Learn More About 5S

Quality-One offers Quality and Reliability Support for Product and Process Development through Consulting, Training and Project Support. Quality-One provides Knowledge, Guidance and Direction in Quality and Reliability activities, tailored to your unique wants, needs and desires. Let us help you Discover the Value of 5S Consulting , 5S Training or 5S Project Support .

Contact Us | Discover the Value!

(248) 280-4800 | [email protected]

Remember Me

- Don't have an account? Register

- Lost your password? Click here

- Already have an account? Log in

Home PowerPoint Templates Diagrams 5S Diagram Template for PowerPoint

5S Diagram Template for PowerPoint

5S Diagram for PowerPoint is an application of the 5-step diagram design for PowerPoint presentations that you can download and use to create presentations on Lean Manufacturing and Kaizen using the 5S Methodology.

5S model is an organizational methodology to organize and monitor the flow of a process effectively. The 5S model and technique use 5 words: Sort, Straighten, Shine, Systemize, and Sustain. Each has its meaning, and the PowerPoint template depicts all of them in a sequence. Japanese started this concept of 5 stages, leading to the technique of Just in Time Manufacturing, one of the most used in the manufacturing industry. Different stages of the process are shown on the curved arrows .

This professional presentation template shows showing the flow of a process. The presentation template starts with an overview of the process, followed by a description of each stage. The first part elaborates on the Sort step dealing with selecting the necessary resources for the process and removing unnecessary ones. Required items can be listed in bullets for further analysis and monitoring. The next step is arranging all the resources appropriately and fully using them, the Straighten step. Shine includes the monitoring of the process and the environment around it. Systemize reflects quality inspection and modifications of the product to maintain a standard. The final stage is Sustain, which deals with storing and maintaining the products in a flow.

One thing to notice about this circular org chart template is the thin portion around the 5S diagram. It can add some text like the company’s motto or some motivational quote. The layout of this PPT template animates with each stage by focusing only on one stage at a time as the presentation goes on and dims the other stages. It completes a rotation by covering all the stages and highlighting the main points adjacent to the 5S diagram. It can also be used as a 30-60-90-day plan template , with each curved arrow showing a regular interval of some days to make a project timeline .

You must be logged in to download this file.

Favorite Add to Collection

Details (6 slides)

Supported Versions:

Subscribe today and get immediate access to download our PowerPoint templates.

Related PowerPoint Templates

5S Methodology PowerPoint Template

Kaizen PICK Chart Template for PowerPoint

5-Step Horizontal Infographic Diagram for PowerPoint

- My presentations

Auth with social network:

Download presentation

We think you have liked this presentation. If you wish to download it, please recommend it to your friends in any social system. Share buttons are a little bit lower. Thank you!

Presentation is loading. Please wait.

Lean and Quality Management The 5S

Published by Hannah Buchholz Modified over 5 years ago

Similar presentations

Presentation on theme: "Lean and Quality Management The 5S"— Presentation transcript:

HOUSEKEEPING & 5 “S”.

Toyota 5S System SCM 462 Dr. Ron Lembke.

5S THE SECRET TO JAPANESE SUCCESS.

Sort the necessary from the unnecessary Use the Red-Tag technique to highlight unneeded items Manage all removed items Separate the essential from.

A Quality Improvement Plan THE FIVE S’s By: David Black.

6 SIGMA VS. KAIZEN/LEAN Manufacturing Systems Analysis.

United Nations Industrial Development Organization The UNIDO CSR Programme: Reaching out to SMEs worldwide Responsible Entrepreneurs Achievement Programme.

HOUSEKEEPING & 5 “S”. Housekeeping does not mean only cleanliness, it means much more than only cleanliness.

SELF-DISCIPLINE Shitsuke

SCM 494 Dr. Ron Tibben-Lembke

5S A guide to understanding and developing 5S in the workplace.

Stability & Standardization. 7 Types of Waste7 Types of Waste Motion (Unnecessary movement) Waiting Transportation or conveyance Storage (Excess.

5S Essentials Five action verbs.

Principles of Six Sigma

1 © 2005 Superfactory™. All Rights Reserved. Lean Office - 5S and Visual Controls Superfactory Excellence Program™

1 Chapter 10 Principles of Six Sigma. Key Idea Although we view quality improvement tools and techniques from the perspective of Six Sigma, it is important.

Lean Training 5S. Agenda What is it? What’s it for? How does it work? When do you use it? What’s an example?

Introduction to 5S. What is 5S? An easy definition is: Finding a place for everything and putting everything in its place. 5S is also the foundation for.

MANAGING FOR QUALITY AND PERFORMANCE EXCELLENCE, 7e, © 2008 Thomson Higher Education Publishing 1 Chapter 10 Principles of Six Sigma.

About project

© 2024 SlidePlayer.com Inc. All rights reserved.

1-866-402-4776 M-F 6am - 4pm PST

Label Samples | Floor Tape Samples

Free Resources

Oops, something went wrong. Please try again.

You are now logged in!

Home Collections Infographics 5s Diagram 5S Quality PPT

5S Quality Google Slides & PowerPoint Template Presentation

Flower Shaped Colorful Nodes:

About this template:, features of this template:.

- 100% customizable slides and easy to download

- Slides are available in different nodes & colors.

- The slides contained 16:9 and 4:3 formats.

- Easy to change the slide colors quickly.

- Well-crafted Template with an instant download facility.

- Crisp and elegant font style.

- The best Template with attractive nodes.

- flower model

- 5S Quality System

- 5S Quality Framework

- 5s Methodology

- 5s Assessment

- 5s Framework

- 5s Plan Diagram

- 5S Quality Infographics

- Flower Model

- Google Slides

Infographics

2696+ Templates

644+ Templates

581+ Templates

Stage / Stairs

831+ Templates

90+ Templates

4978+ Templates

186+ Templates

277+ Templates

204+ Templates

2780+ Templates

You May Also Like These PowerPoint Templates

- Popular Categories

Powerpoint Templates

Icon Bundle

Kpi Dashboard

Professional

Business Plans

Swot Analysis

Gantt Chart

Business Proposal

Marketing Plan

Project Management

Business Case

Business Model

Cyber Security

Business PPT

Digital Marketing

Digital Transformation

Human Resources

Product Management

Artificial Intelligence

Company Profile

Acknowledgement PPT

PPT Presentation

Reports Brochures

One Page Pitch

Interview PPT

All Categories

Powerpoint Templates and Google slides for 5s

Save your time and attract your audience with our fully editable ppt templates and slides..

Item 1 to 60 of 227 total items

- You're currently reading page 1

This complete deck can be used to present to your team. It has PPT slides on various topics highlighting all the core areas of your business needs. This complete deck focuses on 5s Implementation Plan Goals Company Workplace Framework Business Standardize Components and has professionally designed templates with suitable visuals and appropriate content. This deck consists of total of twelev slides. All the slides are completely customizable for your convenience. You can change the colour, text and font size of these templates. You can add or delete the content if needed. Get access to this professionally designed complete presentation by clicking the download button below.

Deliver a credible and compelling presentation by deploying this 5s Lean Powerpoint Ppt Template Bundles. Intensify your message with the right graphics,images,icons,etc. presented in this complete deck. This PPT template is a great starting point to convey your messages and build a good collaboration. The twelve slides added to this PowerPoint slideshow helps you present a thorough explanation of the topic. You can use it to study and present various kinds of information in the form of stats,figures,data charts,and many more. This 5s Lean Powerpoint Ppt Template Bundles PPT slideshow is available for use in standard and widescreen aspects ratios. So,you can use it as per your convenience. Apart from this,it can be downloaded in PNG,JPG,and PDF formats,all completely editable and modifiable. The most profound feature of this PPT design is that it is fully compatible with Google Slides making it suitable for every industry and business domain.

Deliver this complete deck to your team members and other collaborators. Encompassed with stylized slides presenting various concepts, this 5s Audit Scorecard Powerpoint Presentation Slides is the best tool you can utilize. Personalize its content and graphics to make it unique and thought-provoking. All the seventeen slides are editable and modifiable, so feel free to adjust them to your business setting. The font, color, and other components also come in an editable format making this PPT design the best choice for your next presentation. So, download now.

Deliver a lucid presentation by utilizing this The 5s System Powerpoint Ppt Template Bundles. Use it to present an overview of the topic with the right visuals, themes, shapes, and graphics. This is an expertly designed complete deck that reinforces positive thoughts and actions. Use it to provide visual cues to your audience and help them make informed decisions. A wide variety of discussion topics can be covered with this creative bundle such as fourteen. All the fourteen slides are available for immediate download and use. They can be edited and modified to add a personal touch to the presentation. This helps in creating a unique presentation every time. Not only that, with a host of editable features, this presentation can be used by any industry or business vertical depending on their needs and requirements. The compatibility with Google Slides is another feature to look out for in the PPT slideshow.

Introduce your topic and host expert discussion sessions with this 5s Process Management Financial Planning Intelligence Analysis. This template is designed using high-quality visuals, images, graphics, etc, that can be used to showcase your expertise. Different topics can be tackled using the twelve slides included in this template. You can present each topic on a different slide to help your audience interpret the information more effectively. Apart from this, this PPT slideshow is available in two screen sizes, standard and widescreen making its delivery more impactful. This will not only help in presenting a birds-eye view of the topic but also keep your audience engaged. Since this PPT slideshow utilizes well-researched content, it induces strategic thinking and helps you convey your message in the best possible manner. The biggest feature of this design is that it comes with a host of editable features like color, font, background, etc. So, grab it now to deliver a unique presentation every time.

Presenting lean manufacturing 5s checklist presentation examples. This is a lean manufacturing 5s checklist presentation examples. This is a five stage process. The stages in this process are sort, set in order, shine, standardize, sustain.

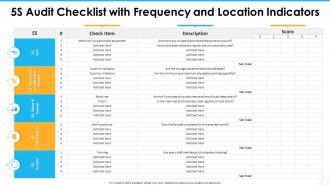

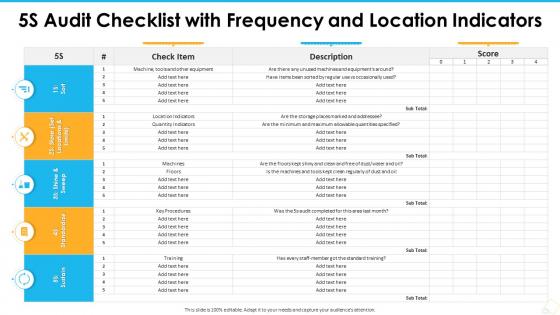

Present the topic in a bit more detail with this 5S Audit Checklist With Frequency And Location Indicators Ppt Slides Template. Use it as a tool for discussion and navigation on Location Indicators, Quantity Indicators, Equipments. This template is free to edit as deemed fit for your organization. Therefore download it now.

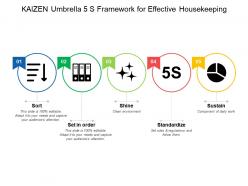

Presenting this set of slides with name Kaizen Umbrella 5 S Framework For Effective Housekeeping. This is a five stage process. The stages in this process are Kaizen Umbrella, Various Elements, Process. This is a completely editable PowerPoint presentation and is available for immediate download. Download now and impress your audience.

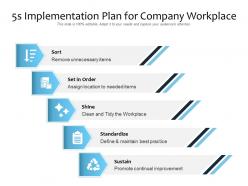

Presenting this set of slides with name 5s Implementation Plan For Company Workplace. This is a five stage process. The stages in this process are 5s Implementation Plan, Company Workplace. This is a completely editable PowerPoint presentation and is available for immediate download. Download now and impress your audience.

Presenting our set of slides with name 5s For Improve Workplace Team Efficiency. This exhibits information on five stages of the process. This is an easy-to-edit and innovatively designed PowerPoint template. So download immediately and highlight information on Sort, Principles, Examples, Standardize, Sustain, Shine, Set In Order.

We are proud to present our 1214 5s seiri seiso seiton seiketsu shitsuke powerpoint presentation. This Power Point template has been crafted with graphic of 5S. This PPT contains the 5S practices for business and production. Use this PPT for your production practices related presentations.

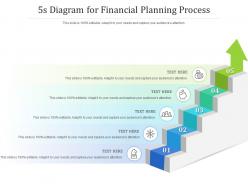

This is our 5s Diagram For Financial Planning Process Infographic Template designed in PowerPoint, however, you can also access it in Google Slides. It comes in two aspect ratios standard and widescreen, with fully editable visual content.

Presenting our set of slides with name 5s Model For Maintaining Organizational Procedures. This exhibits information on five stages of the process. This is an easy-to-edit and innovatively designed PowerPoint template. So download immediately and highlight information on Sort, Streamline, Shine, Standardize, Sustain.

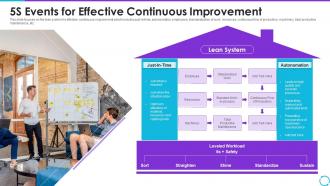

This slide focuses on the lean system for effective continuous improvement which includes just in time, autonomation, employees, standardization of work, resources, continuous flow of production, machinery, total productive maintenance, etc. Presenting our set of slides with 5s Events For Effective Continuous Improvement. This exhibits information on one stages of the process. This is an easy to edit and innovatively designed PowerPoint template. So download immediately and highlight information on 5s Events For Effective Continuous Improvement.

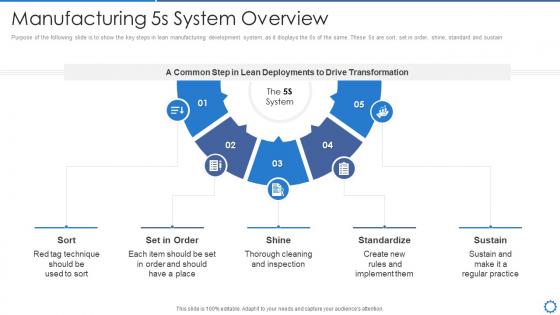

Purpose of the following slide is to show the key steps in lean manufacturing development system, as it displays the 5s of the same. These 5s are sort, set in order, shine, standard and sustain Introducing Manufacturing 5s System Overview Manufacturing Operation Best Practices to increase your presentation threshold. Encompassed with five stages, this template is a great option to educate and entice your audience. Dispence information on Standardize, Manufacturing, Overview, using this template. Grab it now to reap its full benefits.

Deploy our 5s For Business Intelligence Analysis Infographic Template to present high quality presentations. It is designed in PowerPoint and is available for immediate download in standard and widescreen sizes. Not only this, but this layout is also 100 percent editable, giving you full control over its applications.

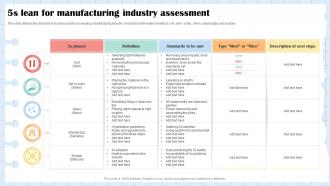

This slide defines the checklist of 5s lean used for assessing manufacturing industry. It includes information related to sort, set in order, shine, standardize and sustain. Introducing our 5s Lean For Manufacturing Industry Assessment set of slides. The topics discussed in these slides are 5s Lean, Manufacturing Industry Assessment. This is an immediately available PowerPoint presentation that can be conveniently customized. Download it and convince your audience.

Great for entrepreneurs, marketing and sales persons. Convert PPT slides font, text, color and blueprint as per your approach. Quick downloading speed and formats can be changed to JPEG and PDF. Easy data entry like company logo, name or trademark. This PowerPoint theme is completely compatible with Google slides. Quality of picture remain unaffected even when we project the image on wide screen.

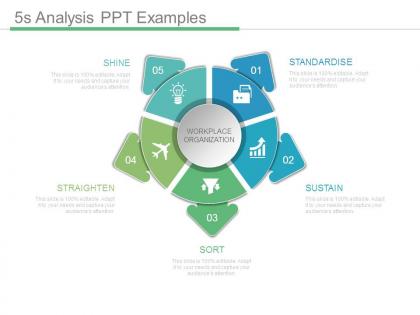

Presenting 5s analysis ppt examples. This is a 5s analysis ppt examples. This is a five stage process. The stages in this process are standardise, sustain, sort, straighten, shine, workplace organization.

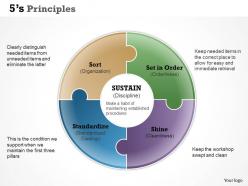

Presenting this set of slides with name - Implementation Process Of 5s. This is a five stage process. The stages in this process are Implementation Process, Execution Process, Implementation Procedure.

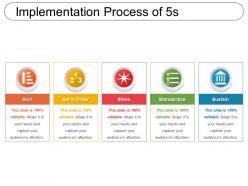

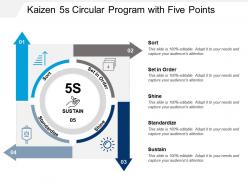

Presenting this set of slides with name Kaizen 5s Circular Program With Five Points. This is a five process. The stages in this process are stages Kaizen 5s Program, Management, Marketing. This is a completely editable PowerPoint presentation and is available for immediate download. Download now and impress your audience.

Presenting Kaizen 5S Framework. These slides are 100 percent made in PowerPoint and are compatible with all screen types and monitors. They also support Google Slides. Premium Customer Support available. Suitable for use by managers, employees, and organizations. These slides are easily customizable. You can edit the color, text, icon, and font size to suit your requirements.

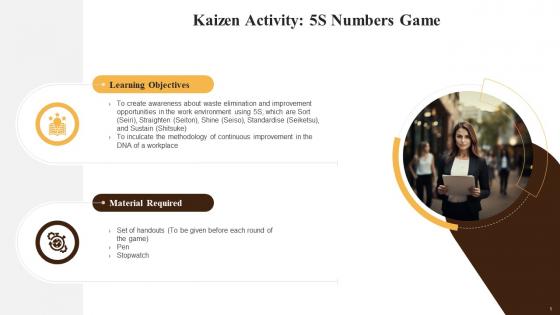

Presenting Kaizen Activity 5S Number Game. This PPT presentation is meticulously researched and each slide consists of relevant content. Designed by SlideTeams PowerPoint experts, this PPT is fully customizable alter the colors, text, icons, and font size to meet your requirements. Compatible with Google Slides and backed by excellent customer support. Download to present with poise and assurance.

Presenting 5S Framework for Kaizen. This PPT presentation is thoroughly researched and each slide consists of appropriate content. Designed by PowerPoint specialists, this PPT is fully customizable alter the colors, text, icons, and font size to meet your needs. Compatible with Google Slides and backed by superior customer support. Download today to deliver your presentation confidently.

Presenting Sorting in 5S Methodology. This PPT presentation is meticulously researched and each slide consists of relevant content. Designed by SlideTeams PowerPoint experts, this PPT is fully customizable alter the colors, text, icons, and font size to meet your requirements. Compatible with Google Slides and backed by excellent customer support. Download to present with poise and assurance.

Presenting Sorting Approach for 5S Principles. This PPT presentation is thoroughly researched by the experts, and every slide consists of appropriate content. It is well crafted and designed by our PowerPoint specialists. Suitable for use by managers, employees, and organizations. You can edit the color, text, icon, and font size to suit your requirements. The PPT also supports Google Slides. Even Premium Customer Support is also available. Download now and present with confidence.

Presenting Setting in Order of 5S Methodology. This PPT presentation is thoroughly researched and each slide consists of appropriate content. Designed by PowerPoint specialists, this PPT is fully customizable alter the colors, text, icons, and font size to meet your needs. Compatible with Google Slides and backed by superior customer support. Download today to deliver your presentation confidently.

Presenting Techniques for Setting in Order Stage of 5S Methodology. This PPT presentation is meticulously researched and each slide consists of relevant content. Designed by SlideTeams PowerPoint experts, this PPT is fully customizable alter the colors, text, icons, and font size to meet your requirements. Compatible with Google Slides and backed by excellent customer support. Download to present with poise and assurance.

Presenting Principle Shining of 5S Methodology. This PPT presentation is thoroughly researched by the experts, and every slide consists of appropriate content. It is well crafted and designed by our PowerPoint specialists. Suitable for use by managers, employees, and organizations. You can edit the color, text, icon, and font size to suit your requirements. The PPT also supports Google Slides. Even Premium Customer Support is also available. Download now and present with confidence.

Presenting Strategies for Shining Stage of 5S Framework. This PPT presentation is thoroughly researched and each slide consists of appropriate content. Designed by PowerPoint specialists, this PPT is fully customizable alter the colors, text, icons, and font size to meet your needs. Compatible with Google Slides and backed by superior customer support. Download today to deliver your presentation confidently.

Presenting Standardizing in 5S Methodology. This PPT presentation is meticulously researched and each slide consists of relevant content. Designed by SlideTeams PowerPoint experts, this PPT is fully customizable alter the colors, text, icons, and font size to meet your requirements. Compatible with Google Slides and backed by excellent customer support. Download to present with poise and assurance.

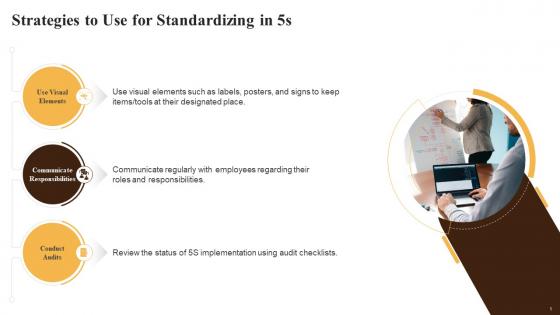

Presenting Strategies to Use for Standardizing in 5s. This PPT presentation is thoroughly researched by the experts, and every slide consists of appropriate content. It is well crafted and designed by our PowerPoint specialists. Suitable for use by managers, employees, and organizations. You can edit the color, text, icon, and font size to suit your requirements. The PPT also supports Google Slides. Even Premium Customer Support is also available. Download now and present with confidence.

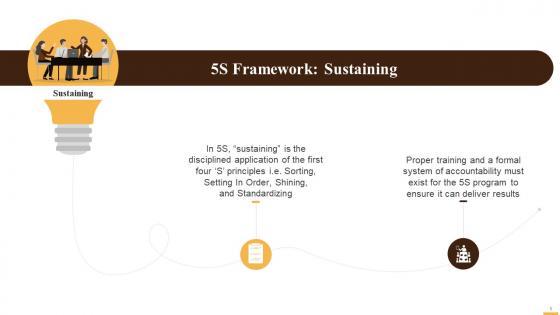

Presenting Sustaining in 5S Framework. This PPT presentation is thoroughly researched and each slide consists of appropriate content. Designed by PowerPoint specialists, this PPT is fully customizable alter the colors, text, icons, and font size to meet your needs. Compatible with Google Slides and backed by superior customer support. Download today to deliver your presentation confidently.

Presenting Strategies to Sustain Gains from 5S Program. This PPT presentation is meticulously researched and each slide consists of relevant content. Designed by SlideTeams PowerPoint experts, this PPT is fully customizable alter the colors, text, icons, and font size to meet your requirements. Compatible with Google Slides and backed by excellent customer support. Download to present with poise and assurance.

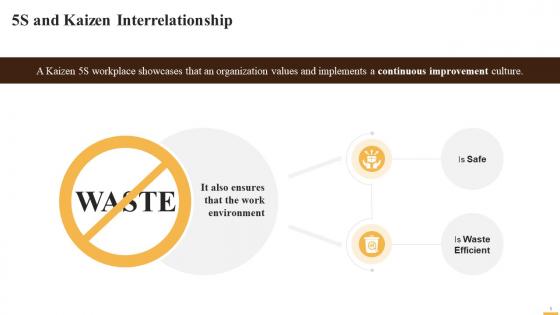

Presenting Interrelationship between 5S and Kaizen. This PPT presentation is thoroughly researched by the experts, and every slide consists of appropriate content. It is well crafted and designed by our PowerPoint specialists. Suitable for use by managers, employees, and organizations. You can edit the color, text, icon, and font size to suit your requirements. The PPT also supports Google Slides. Even Premium Customer Support is also available. Download now and present with confidence.

Presenting Benefits of 5S Kaizen to Businesses. This PPT presentation is thoroughly researched and each slide consists of appropriate content. Designed by PowerPoint specialists, this PPT is fully customizable alter the colors, text, icons, and font size to meet your needs. Compatible with Google Slides and backed by superior customer support. Download today to deliver your presentation confidently.

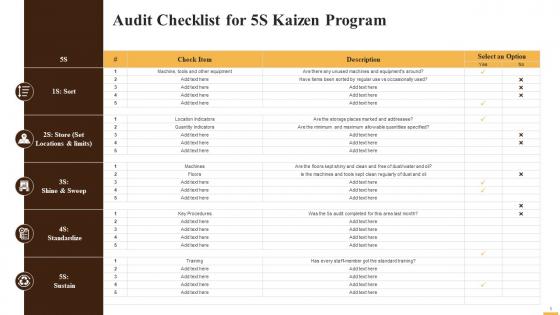

Presenting Audit Checklist for 5S Kaizen Program. This PPT presentation is meticulously researched and each slide consists of relevant content. Designed by SlideTeams PowerPoint experts, this PPT is fully customizable alter the colors, text, icons, and font size to meet your requirements. Compatible with Google Slides and backed by excellent customer support. Download to present with poise and assurance.

If you require a professional template with great design, then this 5s Workplace Efficiency Warehouse Management Organizational Procedures is an ideal fit for you. Deploy it to enthrall your audience and increase your presentation threshold with the right graphics, images, and structure. Portray your ideas and vision using twelve slides included in this complete deck. This template is suitable for expert discussion meetings presenting your views on the topic. With a variety of slides having the same thematic representation, this template can be regarded as a complete package. It employs some of the best design practices, so everything is well-structured. Not only this, it responds to all your needs and requirements by quickly adapting itself to the changes you make. This PPT slideshow is available for immediate download in PNG, JPG, and PDF formats, further enhancing its usability. Grab it by clicking the download button.

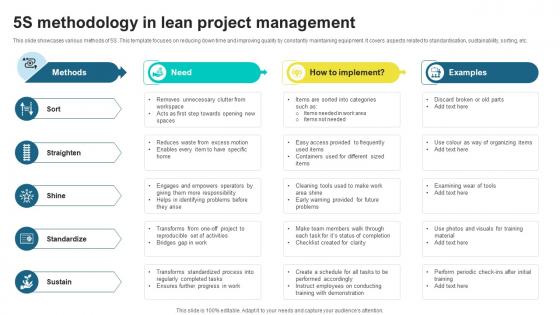

This slide showcases various methods of 5S. This template focuses on reducing down time and improving quality by constantly maintaining equipment. It covers aspects related to standardisation, sustainability, sorting, etc. Introducing 5S Methodology In Lean Project Sculpting Success A Guide To Lean Project Management PM SS to increase your presentation threshold. Encompassed with five stages, this template is a great option to educate and entice your audience. Dispence information on Sort, Straighten, Shine, Standardize, using this template. Grab it now to reap its full benefits.

Unique presentation of business concept. Adjustable with multiple topics related to sales and marketing. Compatible with numerous format options. Harmonious with big set of software. High resolution. No issue of pixilation when projected on wide screen. 100 percent editable. Modify the slide content as per individual preference. Personalize the presentation with company name and logo. Used by marketers, financiers, HR professionals, sales people, students and teachers.

Presenting ppt 5s in the workplace presentation background images. This is a 5s in the workplace presentation background images. This is a five stage process. The stages in this process are sort, set in order, sustain, shine, standardize.

Presenting lean manufacturing 5s principles presentation pictures. This is a lean manufacturing 5s principles presentation pictures. This is a four stage process. The stages in this process are sort, set in order, shine, standardize, sustain.

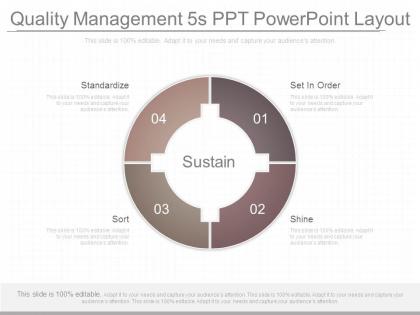

Presenting quality management 5s ppt powerpoint layout. This is a quality management 5s ppt powerpoint layout. This is a four stage process. The stages in this process are set in order, shine, sort, standardize, sustain.

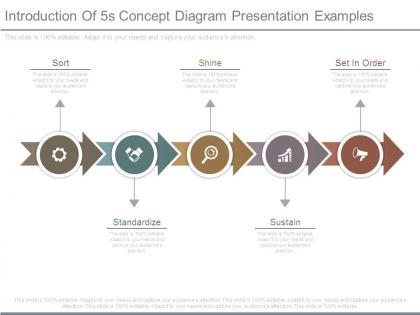

Presenting introduction of 5s concept diagram presentation examples. This is a introduction of 5s concept diagram presentation examples. This is a five stage process. The stages in this process are sort, shine, set in order, sustain, standardize.

Presenting 5s in the workplace powerpoint presentation examples. This is a 5s in the workplace powerpoint presentation examples. This is a five stage process. The stages in this process are sustain, standardize, shine, set in order, sort.

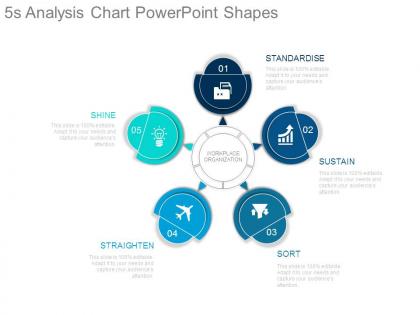

Presenting 5s analysis chart powerpoint shapes. This is a 5s analysis chart powerpoint shapes. This is a five stage process. The stages in this process are sustain, sort, straighten, shine, standardise, workplace organization.

Presenting 5s analysis presentation powerpoint. This is a 5s analysis presentation powerpoint. This is a five stage process. The stages in this process are standardize, sustain, sort, shine, straighten.

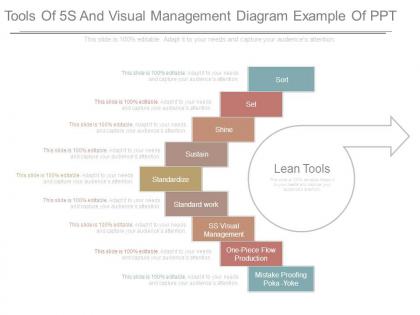

Presenting tools of 5s and visual management diagram example of ppt. This is a tools of 5s and visual management diagram example of ppt. This is a nine stage process. The stages in this process are sort, set, shine, sustain, standardize, standard work, ss visual management, one piece flow production, mistake proofing poka yoke, lean tools.

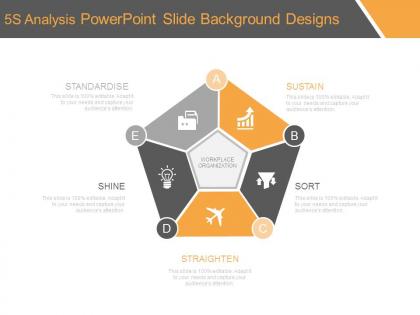

Presenting 5s analysis powerpoint slide background designs. Presenting 5s analysis powerpoint slide background designs. This is a 5s analysis powerpoint slide background designs. This is a five stage process. The stages in this process are standardise, shine, straighten, sort, sustain, workplace organization.

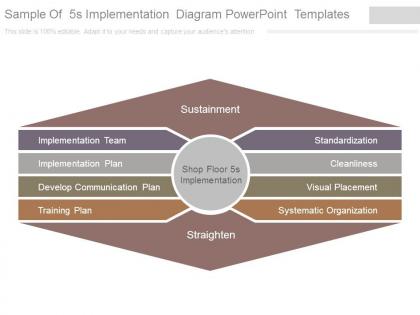

Presenting sample of 5s implementation diagram powerpoint templates. Presenting sample of 5s implementation diagram powerpoint templates. This is a sample of 5s implementation diagram powerpoint templates. This is a eight stage process. The stages in this process are implementation team, implementation plan, develop communication plan, training plan, straighten, systematic organization, visual placement, cleanliness, standardization, sustainment.

Presenting 5s scoring result powerpoint slide templates. This is a 5s scoring result powerpoint slide templates. This is a one stage process. The stages in this process are straighten, shine, standardize, sustain.

This is an editable three stages graphic that deals with topics like Lean Kaizen 9 Step, Tpm 5s Training, Kaizen Event Characteristic to help convey your message better graphically. This product is a premium product available for immediate download, and is 100 percent editable in Powerpoint. Download this now and use it in your presentations to impress your audience.

Presenting this set of slides with name - 5s Continuous Process Improvement Ppt Powerpoint Presentation Layouts Graphics Template Cpb. This is an editable three stages graphic that deals with topics like 5s Continuous Process Improvement to help convey your message better graphically. This product is a premium product available for immediate download, and is 100 percent editable in Powerpoint. Download this now and use it in your presentations to impress your audience.

Presenting this set of slides with name - 5s Kanban Kaizens Ppt Powerpoint Presentation Layouts Graphics Tutorials Cpb. This is an editable three stages graphic that deals with topics like 5s Kanban Kaizens to help convey your message better graphically. This product is a premium product available for immediate download, and is 100 percent editable in Powerpoint. Download this now and use it in your presentations to impress your audience.

Presenting this set of slides with name - 5s Lean Manufacturing Dmaic Ppt Powerpoint Presentation Pictures Tips Cpb. This is an editable three stages graphic that deals with topics like 5s Lean Manufacturing Dmaic to help convey your message better graphically. This product is a premium product available for immediate download, and is 100 percent editable in Powerpoint. Download this now and use it in your presentations to impress your audience.

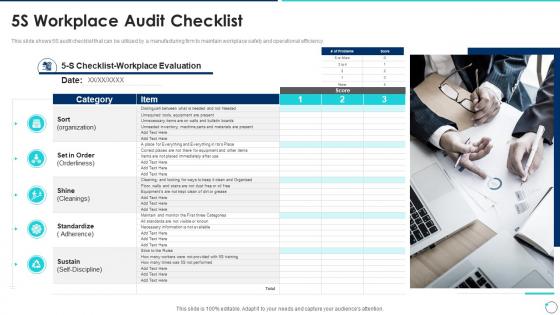

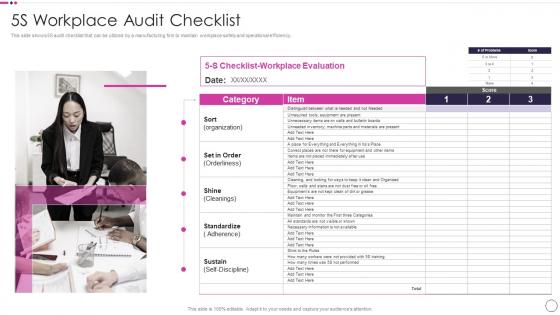

This slide shows 5S audit checklist that can be utilized by a manufacturing firm to maintain workplace safety and operational efficiency.Introducing 5s Workplace Audit Checklist Collection Of Quality Control Templates Ppt Brochure to increase your presentation threshold. Encompassed with five stages, this template is a great option to educate and entice your audience. Dispence information on Distinguish Between, Placed Immediately, Maintain And Monitor using this template. Grab it now to reap its full benefits.

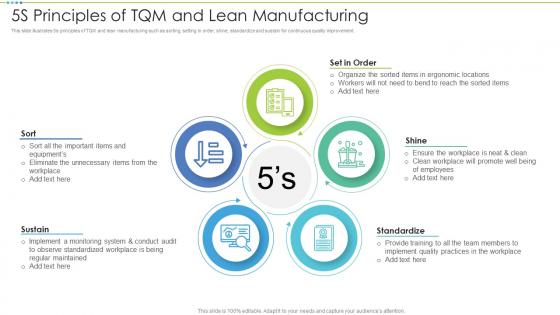

This slide illustrates 5s principles of TQM and lean manufacturing such as sorting, setting in order, shine, standardize and sustain for continuous quality improvement. Presenting our set of slides with 5s Principles Of TQM And Lean Manufacturing. This exhibits information on five stages of the process. This is an easy to edit and innovatively designed PowerPoint template. So download immediately and highlight information on Sustain, Shine, Standardize.

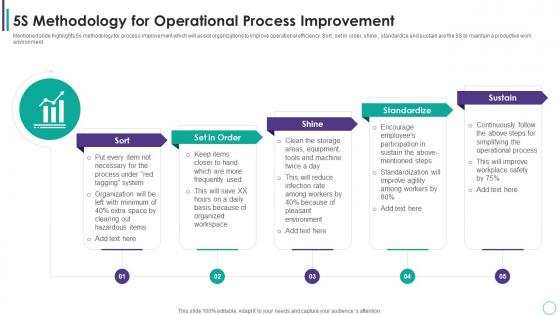

Mentioned slide highlights 5s methodology for process improvement which will assist organizations to improve operational efficiency. Sort, set in order, shine , standardize and sustain are the 5S to maintain a productive work environment.Introducing our premium set of slides with 5s Methodology For Operational Process Improvement Ellicudate the five stages and present information using this PPT slide. This is a completely adaptable PowerPoint template design that can be used to interpret topics like Clearing Out Hazardous Items, Equipment Tools And Machine, Participation In Sustain. So download instantly and tailor it with your information.

This slide shows 5S audit checklist that can be utilized by a manufacturing firm to maintain workplace safety and operational efficiency. Deliver an outstanding presentation on the topic using this 5s Workplace Audit Checklist Quality Assurance Plan And Procedures Set 1. Dispense information and present a thorough explanation of Organization, Standardize, Orderliness using the slides given. This template can be altered and personalized to fit your needs. It is also available for immediate download. So grab it now.

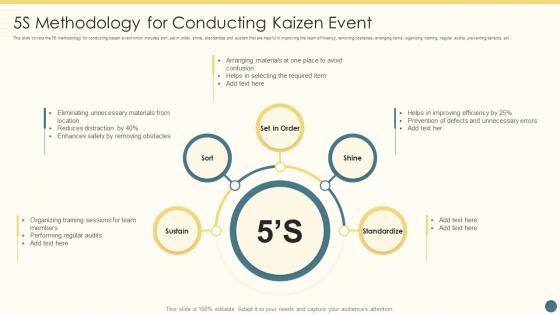

This slide covers the 5S methodology for conducting kaizen event which includes sort, set in order, shine, standardize and sustain that are helpful in improving the team efficiency, removing obstacles, arranging items, organizing training, regular audits, preventing defects, etc. Introducing our premium set of slides with 5S Methodology For Conducting Kaizen Event. Elucidate the five stages and present information using this PPT slide. This is a completely adaptable PowerPoint template design that can be used to interpret topics like Organizing Training Sessions, Team Members, Location. So download instantly and tailor it with your information.

The following slide displays the upward moving arrow of 5s process as it displays the key steps such as sort, set in order, shin, standardize and sustain Introducing 5s For Operation And Manufacturing Operation Best Practices to increase your presentation threshold. Encompassed with five stages, this template is a great option to educate and entice your audience. Dispence information on Manufacturing, Standardize, Set In Order, using this template. Grab it now to reap its full benefits.

Purpose of the following slide is to show the key 5s steps such as sort, set in order, shine, standardize and sustainability , these can help the origination to obtain operational efficiency. Introducing Manufacturing Operation Best Practices 5s System For Manufacturing And Operations to increase your presentation threshold. Encompassed with five stages, this template is a great option to educate and entice your audience. Dispence information on Standardize, Implement, Operations, using this template. Grab it now to reap its full benefits.

This slide covers the checklist which must be maintained by the company to follow the steps involved in 1st pillar of TPM. Introducing Total Productivity Maintenance Checklist Needed To Consider 5S In The Company to increase your presentation threshold. Encompassed with one stages, this template is a great option to educate and entice your audience. Dispence information on Checklist Needed, Consider 5S Company, using this template. Grab it now to reap its full benefits.

This slide covers the 1st pillar of TPM which is 5s foundation that focuses on sort, set locations, shine, standardizing, and sustain. Introducing Total Productivity Maintenance Tpm Pillar 1 The 5S Foundation to increase your presentation threshold. Encompassed with four stages, this template is a great option to educate and entice your audience. Dispence information on Standardising, Sort, Set Locations, Shine And Sweep, Eliminate, Performing, Clean And Inspect, Organize Remaining Items, using this template. Grab it now to reap its full benefits.

Introducing 5S Audit Checklist For Lean Manufacturing Ppt Slides Icons to increase your presentation threshold. Encompassed with five stages, this template is a great option to educate and entice your audience. Dispence information on Checklist, Measures, Success, using this template. Grab it now to reap its full benefits.

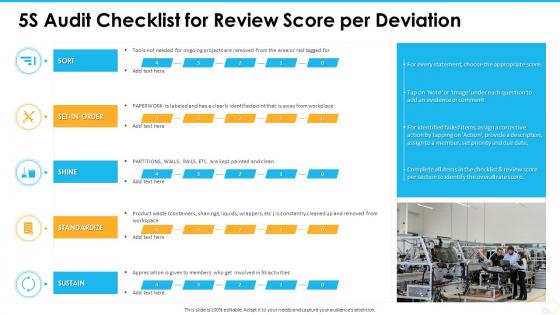

Increase audience engagement and knowledge by dispensing information using 5S Audit Checklist For Review Score Per Deviation Ppt Slides Background. This template helps you present information on five stages. You can also present information on 5s Audit Checklist, Review Score, Per Deviation, Sort, Set In Order, Shine, Standardize, Sustain using this PPT design. This layout is completely editable so personaize it now to meet your audiences expectations.

Introducing our Icon Slide For 5S Audit Scorecard template to enhance your presentation. The slide displays eye catching icons that can be incorporated into any business presentation. Download it instantly and edit as per your knowledge.

Presenting our set of slides with 5s Methodology For Lean Manufacturing Management. This exhibits information on five stages of the process. This is an easy to edit and innovatively designed PowerPoint template. So download immediately and highlight information on Self Standardize, Sustain, Streamline.

Introducing Key Business Processes And Activities For Excellence 5s Lean Workplace to increase your presentation threshold. Encompassed with three stages, this template is a great option to educate and entice your audience. Dispence information on Organization, Technique, Workspace, using this template. Grab it now to reap its full benefits.

Presenting our set of slides with 5S Lean Warehouse Operations Management. This exhibits information on five stages of the process. This is an easy to edit and innovatively designed PowerPoint template. So download immediately and highlight information on Sort, Streamline, Shine, Standardize, Sustain.

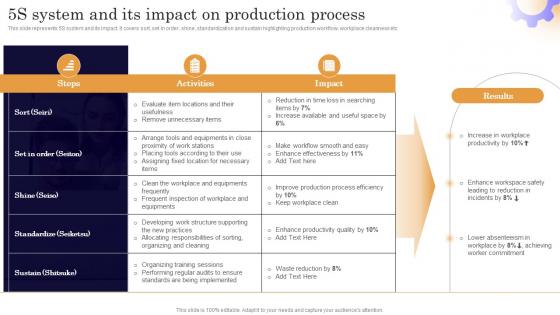

This slide represents 5S system and its impact. It covers sort, set in order, shine, standardization and sustain highlighting production workflow, workplace cleanness etc. Present the topic in a bit more detail with this 5S System And Its Impact On Production Executing Lean Production System To Enhance. Use it as a tool for discussion and navigation on Unnecessary Items, Organizing And Cleaning, Productivity Quality. This template is free to edit as deemed fit for your organization. Therefore download it now.

Got any suggestions?

We want to hear from you! Send us a message and help improve Slidesgo

Top searches

Trending searches

infertility

30 templates

16 templates

49 templates

27 templates

frida kahlo

56 templates

el salvador

32 templates

Kaizen, Quality Management Method

Kaizen, quality management method presentation, free google slides theme and powerpoint template.

The Kaizen method is a philosophy of continuous improvement that has gained popularity in the business world. The concept is simple yet powerful: small, incremental changes lead to significant progress over time. Slidesgo wasn't built in one day—it's been a journey of small steps until we got to the top! We have prepared this template, with some Japanese inspiration, to make it easy for you to explain the Kaizen method and, possibly, propose it in your own business. It includes a calligraphic font for the titles and completely editable slides.

Features of this template

- 100% editable and easy to modify

- 35 different slides to impress your audience

- Contains easy-to-edit graphics such as graphs, maps, tables, timelines and mockups

- Includes 500+ icons and Flaticon’s extension for customizing your slides

- Designed to be used in Google Slides and Microsoft PowerPoint

- 16:9 widescreen format suitable for all types of screens

- Includes information about fonts, colors, and credits of the resources used

How can I use the template?

Am I free to use the templates?

How to attribute?

Attribution required If you are a free user, you must attribute Slidesgo by keeping the slide where the credits appear. How to attribute?

Related posts on our blog.

How to Add, Duplicate, Move, Delete or Hide Slides in Google Slides

How to Change Layouts in PowerPoint

How to Change the Slide Size in Google Slides

Related presentations.

Premium template

Unlock this template and gain unlimited access

IMAGES

VIDEO

COMMENTS

What are the Five S's (5S) of Lean. Quality Glossary Definition: Five S's (5S) 5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment, both physically and mentally.

5S Shitsuke Sustain - The fifth and final stage of 5S implementation. Lean 6S ppt Training Presentation; 6S - How does 6S differ from 5S and why?. Presentations Supporting Your 5S Training; 5S Red Tag - Learn how to use 5S Red Tags. Runners Repeaters Strangers - Learn how to apply RRS techniques when implementing 5S. Presentation Detailing How to Plan and Conduct Your 5S Implementation;

5S Training Presentation. Aug 27, 2015 •. 37 likes • 98,977 views. Parth Devariya. 5S is short for: Sort, Set in Order, Shine, Standardize and Sustain. 5S represents 5 disciplines for maintaining a visual workplace. #5S #5S Training #Business #BusinessManagement. Read more. Leadership & Management. 1 of 15. Download Now.

5S. 5S is a five-step methodology that, when followed, creates a more organized and productive workspace. In English, the 5S's are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.

These 5s PowerPoint Presentation Templates dеmonstratе with high quality visuals thе transformation that can occur when chaos is еliminatеd, and efficiency is еmbracеd. Mеanwhilе this list of our Top 10 5s Powerpoint Presentation Templates' providеs a structurеd framework for еvaluating currеnt practicеs and highlighting areas of ...

The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace. Improved visual controls are implemented as part of 5S to make any process non-conformance's obvious and easily detectable. 5S is often one element of a larger Lean initiative and promotes continuous ...

PowerPoint presentation slides. : The slide showcases the 5s principle a quality improvement tool used for organizing workspace and optimizing business operations. it covers five practices for continuous improvement sort, set in order, shine, standardize and sustain. Presenting our set of slides with 5s Model For Continuous Quality Improvement.

Give your team the 5S foundation they need to get Lean with this ...

768 likes • 160,701 views. Operational Excellence Consulting. The 5S workplace organization system applies a set of basic management principles that many companies widely adopt to maximize productivity and organization. As a cornerstone of Lean management, 5S improves workplace morale, safety and efficiency. In this training presentation, you ...

5S Diagram for PowerPoint is an application of the 5-step diagram design for PowerPoint presentations that you can download and use to create presentations on Lean Manufacturing and Kaizen using the 5S Methodology.. 5S model is an organizational methodology to organize and monitor the flow of a process effectively. The 5S model and technique use 5 words: Sort, Straighten, Shine, Systemize, and ...

History. 5S Lean was developed by Hiroyuki Hirano in post-war Japan, where it was famously utilized by Toyota. By integrating 5S principles into their already famous manufacturing framework dubbed the Toyota Production System or TPS, Toyota gained international prominence as a prolific producer of high-quality motor vehicles.. Largely due to Toyota's success, companies from a variety of ...

5s presentation, Quality assurance. 5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury.

5S in Quality Management. Download our high-quality 5S in Quality Management PPT to beautifully showcase a step-by-step procedure to implement the 5S to improve the quality of products and services.

Download ppt "Lean and Quality Management The 5S" Similar presentations . HOUSEKEEPING & 5 "S". Toyota 5S System SCM 462 Dr. Ron Lembke. 5S THE SECRET TO JAPANESE SUCCESS. Sort the necessary from the unnecessary Use the Red-Tag technique to highlight unneeded items Manage all removed items Separate the essential from.

Evaluate your facility with this free 5S audit card. Quality ...

This PowerPoint slide features a well-designed illustration incorporated with eye-catching icons to explain the 5S in quality management. The striking color combination will instantly capture your audience's attention. Spellbinding Features. The high-definition quality and resolution will remain intact even after making necessary changes.

What is 5S? 5S is a systematic form of visual management utilizing everything from floor tape to operations manuals. It is not just about cleanliness or orga...