- HAIR & BODY

- HOME & TOOLS

- Derma Treatments

- Doctor Facelift

- Doctors Formula

- Dr Botanicals

- Dr Botanicals Apothecary

- Dr Botanicals Baby

- Dr Botanicals Baby Lux

- Feel Like Beauty

- Gold Serums

- Organic & Botanic

- Skin Research

- Skin Superfood

- skinChemists

- skinChemists London

- skinChemists Youth Series

- skinPharmacy

- Featured Outlet Best Sellers Shop All Accessories Skincare Kits

- Shop Categories Cleansers Exfoliators Eye Care Eye Pads Face Lift Facial Oils Facial Serums Lip Care Mascaras Masks Moisturisers Toners

- Shop Ingredients Bee Venom Collagen Green Caviar Hyaluronic Acid Probiotic Retinol Vitamin C Vitamin D

- Collections Biphase Brightening Cocoa Noir Japanese Orange Moroccan Rose Night Care Pomegranate Rose Quartz Sun Protection SPF Teeth Whitening Wrinkle Killer

- HAIR Conditioners Shampoos Hair Masks Hair Mists

- BODY Body Creams Body Oils Hand Creams Perfumes

- Aromatherapy Candles Diffusers Diffuser Oils

- Tools Beauty Electricals Facial Rollers Makeup Brushes Toothbrush

Your cart is empty

Hydrating Serum Polyglutamic Acid 1%, Vitamin C 3% 30ml

- Provides deep moisturization for hydrated skin

- Enhances complexion with temporary brightness

- Contains Polyglutamic Acid and Vitamin C for intense hydration and a radiant appearance

This formula is a skincare product that aims to provide deep moisturization and a temporary brighter complexion. It contains Polyglutamic Acid for intense hydration and Vitamin C for a radiant appearance. With its focus on hydration and brightening, this formula promotes healthy and hydrated skin.

This formula targets dry and dehydrated skin, promoting hydration and a brighter complexion. It is suitable for all skin types.

Choose options

Free delivery

On orders over £40

Extra 5% off

With code FLB

24/7 Customer service

Satisfied or Refunded

Secure payments

Information is processed securely

CONFIDENCE, COMMUNITY, AND JOY

- Skincare Ingredients A-Z

- Skin Concerns

- Hair Removal

- Moisturizers

- Tools and Techniques

- Hair Concerns

- Hair Styling

- Fashion Trends

- What to Wear

- Accessories

- Clothing and Apparel

- Celebrities

- Product and Brand News

- Trends and Innovation

- Amazon Picks

- Gift Guides

- Product Reviews

- Mental Health and Mood

- The Byrdie Team

- Editorial Guidelines

- Editorial Policy

- Terms of Use and Policies

- Privacy Policy

- Skincare Ingredients A–Z

Polyglutamic Acid Is the Hydrating Hero Ingredient Your Skincare Routine Needs

:max_bytes(150000):strip_icc():format(webp)/cdn.cliqueinc.com__cache__users__618__amy-lawrenson-1-618-1514897570-main_image-e162502b98da4adb8a4f2859c61c39b4.jpg)

Marcos Flores / Pexels

In This Article

About a month ago I heard the words polyglutamic acid (PGA) for the first time. I was listening to Charlotte Tilbury talk about her latest product launches at a virtual event (because that's the new normal). Tilbury was extolling the virtues of this little-known ingredient as a hydrating hero. In fact, she is so enamored with it, she factored it into her Magic Serum ($80).

Meet the Expert

- Charlotte Tilbury is a British makeup artist and the founder and chief creative officer of the makeup and skincare brand Charlotte Tilbury Beauty Ltd.

- Michelle Wong is a cosmetic scientist and the founder of Lab Muffin Beauty Science .

"Polyglutamic acid is a hydration powerhouse!" Tilbury tells Byrdie. "Polyglutamic acid is an incredible humectant that holds four times more moisture than hyaluronic acid (HA)—my skin just drinks it in!"

So why is an ingredient supposedly more moisture-banding than the hydration hero that is hyaluronic acid so little known? I called on Tilbury and scientist Michelle Wong of Lab Muffin Beauty Science to reveal more about the enigma that is polyglutamic acid. Plus, keep scrolling to shop the products that feature this buzzy skincare ingredient.

POLYGLUTAMIC ACID

TYPE OF INGREDIENT: Hydrator

MAIN BENEFITS: Moisturizes skin, reduces the appearance of wrinkles and pores, replenishes cell moisture.

WHO SHOULD USE IT: It is ideal for anyone with dry or dehydrated skin. Polyglutamic acid is safe for all skin types, however, if you have sensitive skin it is always best to patch test a new product.

WHEN YOU CAN USE IT: Polyglutamic acid can be used morning and night.

WORKS WELL WITH: It plays nicely with other skincare ingredients, especially hyaluronic acid and vitamin C.

DON’T USE WITH: There are no known negative reactions with polyglutamic acid.

What Is Polyglutamic Acid?

"Glutamic acid is an amino acid. Polyglutamic acid is created when lots of glutamic acid molecules are linked together," says Wong. "It's produced by bacterial fermentation and is found in Nattō." [Ed note: Nattō is a traditional Japanese food made from fermented soybean.]

Polyglutamic acid is very similar to another buzzy skincare hero, hyaluronic acid but, as experts note, it's perhaps even more moisturizing.

What Are the Skin Benefits?

"It's a very effective humectant that can grab onto water and keep skin hydrated," notes Wong.

"Polyglutamic acid helps seal the moisture in your skin, and enhances the skin’s elasticity," says Tilbury. "Part of the aging process involves the loss of HA in the skin, which is broken down by an enzyme called hyaluronidase. Products that contain PGA help to inhibit the action of hyaluronidase, resulting in more HA in the skin, and giving an overall moisturized, rejuvenated, and hydrated appearance to the skin."

Within her namesake brand's Magic Serum , Tilbury tells us that the PGA hydrates the skin, leading to a plumper-looking complexion and a diminished appearance of pores. "It makes makeup application so much easier too!" she adds.

How Does It Compare to Hyaluronic Acid?

"[Unlike HA], polyglutamic acid doesn't occur naturally in our bodies," Wong says. "Ingredient suppliers claim it can hold 10 times more water than hyaluronic acid, which is very impressive." Tilbury, on the other hand, claims it holds four times as much moisture because of its larger molecular size and can actually help the skin produce more hyaluronic acid. "Not only does it draw water into the cells, like HA, but it also forms a protective film on your skin that prevents water from evaporating," she claims. "I call it my plumper-looking skin filter!"

What both Wong and Tilbury do agree on is that polyglutamic acid is more effective at holding onto moisture than hyaluronic acid, however, don't be so quick to abandon HA in favor of PGA. "I see the two ingredients as friends rather than competitors," says Tilbury. "When used together, they can be seen as the ultimate recipe for hydrated skin."

Why Is It Under-the-Radar?

Polyglutamic acid is relatively new on the beauty market, Wong tells us. According to Tilbury, it also costs more than HA, which affects profit margins and could be one of the reasons we haven't seen it in that many products to date. That being said, as the popularity of this skincare powerhouse increases, we could eventually see more products, at lower price points, enter the market. Already, we see the acid as a key ingredient in at least one trendy skincare line, the Futurwise Slugging System .

Does Polyglutamic Acid Play Nice With All Skin Types?

Tilbury notes that "polyglutamic acid floods the skin with moisture—all skin types require hydration to function optimally but sensitive and dry skin types, in particular, will love the hydration boost this gives." Oily skin could also benefit from polyglutamic acid, but it's best to proceed with caution.

Is It Best Applied via a Serum?

Polyglutamic acid is mostly formulated into serum textures, and Wong tells us that "since it's a general humectant and effective at very low concentrations (as low as 0.1%), it can work well in lots of different formulations. Along with serums, it can be formulated into moisturizers, essences, toners, possibly even sunscreens though I don't know of any on the market yet." It also plays well with makeup, so you can layer it on the skin before adding in your other products .

"As more people learn about the benefits of PGA, it will gain the cult status of HA and we can expect to see it used in more products," predicts Tilbury. "I’m thrilled to have been one of the first to bottle this incredible, supercharged ingredient."

Interactions to Know About

There are no known ingredients that negatively interact with polyglutamic acid. In fact, according to Wong, polyglutamic acid "mixes well with other products, especially water-based ones." In other words, using it in conjunction with moisturizers , oils, etc. is kind of the point, as it can increase the absorption of other ingredients. That being said, if your skin does develop a rash or reacts negatively, it's always best to back off a new product and seek an expert's help.

Side Effects

As with pretty much any type of acid, it's possible to develop an allergic reaction to polyglutamic acid. Signs and symptoms would be red, tingling skin, hives, itchiness or swelling. If you do note any of the above—or find that your skin is dry and scaly rather than moist and well-hydrated—it's time to visit a dermatologist. Acids are sometimes best to introduce to your skin over time, so if you're worried about a negative reaction, try using a polyglutamic-containing product just once per week, and gradually working your way up to every day. This will allow your skin time to tolerate the acid.

Yes, you can use hyaluronic acid and polyglutamic acid together. When used in conjunction, both ingredients work to help moisturize the skin and repair the skin barrier.

Polyglutamic acid can be worn morning or night, and is best applied post-cleanse and prior to serums, moisturizers, sunscreens, or makeup.

Polyglutamic acid is thought to be safe for all skin types, but it works especially well on those with dry skin. As with any skincare ingredient, it's best to exercise caution when introducing a new product into your daily routine.

Related Stories

17 Spring Skincare Launches That Should Be On Your Radar

The 12 Best Foundations for Dry Skin That Offer Coverage and Hydration

The Benefits of Hyaluronic Acid Serums and How to Use Them

Marula Oil Is the Hydrating, Anti-Inflammatory Solution Derms Love—Here’s Why

The 15 Best Anti-Aging Serums to Address Fine Lines, Uneven Skin Texture, and Skin Firmness

The 16 Best Moisturizers for Dry Skin, Tested & Reviewed

How to Use Tranexamic Acid In Your Skincare Routine for a Brighter Complexion

The 12 Best Glycolic Acid Cleansers That Will Make Your Skin Glow

Propanediol: The Skincare Ingredient Derms Want You to Know

The 19 Best Face Moisturizers, Tested and Dermatologist Approved

Malachite Is the Ideal Stress-Reducing Skincare Ingredient for Crystal Lovers

Salicylic Acid Is the Acne-Fighting Ingredient Derms Want You to Use—Here's Why

The 23 Best Anti-Aging Eye Creams of 2024 for Wrinkles, Fine Lines, & Dark Circles

OLAY's New "Super Serum" Cocktails 5 Ingredients Without Irritation

The 12 Best Hyaluronic Acid Serums of 2024, Tested by Byrdie, Approved by Derms

The 15 Best Night Creams for Smooth, Hydrated Skin

Polyglutamic Acid Is Trending — Does It Deserve a Spot in Your Skin-Care Routine?

Updated on 5/5/2023 at 4:35 PM

:upscale()/2024/01/17/607/n/1922153/7ea189e265a7d7887df639.73618175_.jpg)

Thought hyaluronic acid was the best hydrator on the block? Turns out there's a new kid called polyglutamic acid coming for its crown. We know, we know: another day, another buzzy skin-care ingredient that promises to transform your skin. And this time, it's got a name that's not only difficult to say (try: poly-glue-ta-mick) but is also complicated enough to send your predictive text into a complete meltdown.

So, what exactly is polyglutamic acid (also known as PGA) — and is it worth the hype? Can it really rival good old hyaluronic acid, like so many people are claiming? We asked the experts for the lowdown. Keep reading for everything you need to know about polyglutamic acid.

What Is Polyglutamic Acid?

"Polyglutamic acid is a natural, biodegradable polymer of the amino acid glutamic acid produced by fermentation of Japanese soybeans with Bacillus subtilis," Marko Lens , MD, consultant plastic surgeon and founder of Zelens, tells POPSUGAR. That's a lot of science in one sentence, so let's break it down a little.

Polyglutamic acid is a type of ingredient called a peptide and is made up of a chain of a particular type of amino acid called glutamic acid. Still, despite being a peptide, it doesn't work in the same way as antiaging peptides you might have heard of but "acts as a moisturizing agent by locking moisture into the skin," explains Mark Curry , cofounder of The Inkey List.

It's a humectant, like hyaluronic acid , which means its primary role is to attract water like a magnet. Polyglutamic acid is made by fermenting Japanese soybeans with a particular strain of bacteria that can also be found in kimchi. Think of it a bit like the skin-care version of a sourdough starter, just with more bacteria and less yeast.

How Does Polyglutamic Acid Work?

So how does this little chain of amino acids work in our skin? "Polyglutamic acid is a powerhouse humectant that not only puts water into the skin but keeps it there as well," junior doctor and skin expert Kemi Fabusiwa says.

It holds onto this moisture by "creating a barrier over the skin to prevent hydration loss from the inside and prevent dehydration from the outside," says Ahmed El Muntasar , a general practitioner and aesthetician. "Polyglutamic acid can also potentially prevent something called hyaluronidase, which is the enzyme that breaks down hyaluronic acid in the skin." This last benefit is a biggie, as the natural levels of hyaluronic acid in our skin deplete as we age, meaning we're more prone to dehydration the older we get.

Who Is Polyglutamic Acid Good For?

Pretty much anyone can use the ingredient, but you'll see the biggest improvement if your skin is dehydrated or lacking in radiance. "By binding water to the skin, polyglutamic acid is a super, glow-inducing active for dewy skin," says Georgie Cleeve , founder of Oskia Skincare. "Due to its ability to attract water, it will help minimize fine lines and wrinkles and keep skin soft, supple, and healthy as well. PGA also has antioxidant properties, inhibits the production of melanin, and strengthens the barrier function."

"Ultimately, all skin types can benefit from polyglutamic acid as a hydrating active, but particularly mature and dry skin or those with a weakened barrier function," Cleeve says. The only caveat to this is if you have an oily skin type. "If you're someone that's naturally oily, then overhydrating your skin can actually break you out a little bit," Dr. Muntasar says. "I find that sometimes this is a bit of a fine balance." If this sounds like you, introduce polyglutamic acid into your routine slowly and sparingly to avoid blemishes.

As well as improving how your skin looks when you're bare-faced, polyglutamic acid can also improve the finish of your makeup. "By increasing the water content of the epidermis (the top layer of our skin), polyglutamic acid allows your liquid foundations to glide onto the skin better for a more dewy finish," Dr. Fabusiwa says. "Its ability to plump the skin and boost elasticity makes it the perfect partner to your foundation." Wear PGA beneath your base, or mix them together for maximum glow.

Polyglutamic Acid vs. Hyaluronic Acid

How does polyglutamic acid match up to the much-loved hero hydrator hyaluronic acid? "Polyglutamic acid has a large molecular size, while hyaluronic acid can have a much lower molecular weight, which allows significantly deeper penetration," Dr. Lens says. "That's why, in simple terms, I would say that PGA works above the surface and HA works below. Additionally, polyglutamic acid forms a soft, smooth film on the skin, which results in the protection of the outer layer. They are different molecules with different actions, but if we're talking about hydration efficacy, then polyglutamic acid will increase skin's moisture capacity more effectively than HA."

Hyaluronic acid is very good at providing deep-down hydration in the skin, but it is polyglutamic acid's protective film that allows this newer ingredient to deliver more visible, instant results. A nice way to visualize it is to imagine that hyaluronic acid is handing the skin a nice big glass of water. This is great, but unless you follow with moisturiser, it can escape — in the same way that water in an open glass can evaporate or be spilt. Polyglutamic acid is your skin-care equivalent of a sports drink. Not only does it have the extra benefit of electrolytes for more intense rehydration, but it also comes in a bottle with a lid so no liquid is lost.

PGA might be coming out on top in the battle of the humectants, but if you can, it's still more beneficial to use both ingredients in your routine rather than pick and choose. "It's not a competition, it's more of a logistic relationship," Dr. Muntasar says. "They work well together. Polyglutamic acid is a new ingredient that isn't very common or very popular because it is expensive and quite difficult to make, whereas hyaluronic acid is a lot more readily available. If you suffer from very dry skin, you can use both of these ingredients to really target those dry areas."

"Polyglutamic acid and hyaluronic acid are like scones and jam or butter and toast," Cleeve says. "They're the perfect combination, especially when cleverly combined using different molecular weights." For best results, use PGA during the day to create a silky canvas for makeup and HA for deep-down hydration as part of your evening routine.

How to Use Polyglutamic Acid in Your Routine

Polyglutamic acid is a friendly ingredient that plays nicely with other actives and is therefore easy to slot into your routine. "Polyglutamic is a great active to use both a.m. and p.m. and has a place in all products, from cleansers to serums and moisturizers," Cleeve says. "However, the best effect will be in serums and moisturizers." That's because these are left on the skin, rather than washed off, which gives them maximum opportunity to work their magic.

"Polyglutamic acid should always be applied directly against the skin in a water-based product and before anything that contains oils," Cleeve says. This sequence is important because oil is heavier than water. If you put your polyglutamic-acid product on over an oil, the oil will block its path, and the PGA won't be able to make its way into the skin.

Although it has acid in its name, polyglutamic acid doesn't exfoliate the skin, so there's no real risk of overdoing it. How often you use it will depend on your skin type and individual needs. "This is where trial and error really comes into play," Dr. Muntasar says. "Try the product, apply the recommended amounts, and if it works for you, then that's great. If not, you can always add a touch more."

Interested in adding this wonder ingredient to your routine? See some of our favorite polyglutamic-acid-infused skin-care products ahead.

:upscale()/2023/05/05/571/n/29590734/de22546bd8111801_Screenshot_2023-05-05_at_13.42.55.png)

Best Polyglutamic-Acid Sunscreen

The Inkey List Polyglutamic Acid Dewy Sunscreen ($15)

The best SPF is one you want to wear, which is why The Inkey List wanted to create a formula that felt and looked good on skin. Years in the making, this is the result: a nongreasy, super-hydrating formula that leaves skin glowing and protected.

:quality(70):extract_cover():upscale():fill(ffffff)/2023/05/05/571/n/29590734/de22546bd8111801_Screenshot_2023-05-05_at_13.42.55.png)

Best Polyglutamic-Acid Serum

Zelens Melatonin B12 Advanced Repair Serum ($73)

The key ingredients in this premium serum are melatonin and vitamin B12, chosen for their ability to renew and repair the skin. Polyglutamic acid is here in a supporting role, adding extra moisture into the mix so skin can function at its best.

:quality(70):extract_cover():upscale():fill(ffffff)/2023/05/05/876/n/44344577/shopr4oJ9O.jpg)

Best Soothing Polyglutamic Acid

Oskia Rest Day Barrier Repair Balm ($103)

If your skin is throwing a toddler-worthy tantrum, this is the product to get it off the floor and back into its happy place. Polyglutamic acid works alongside soothing colloidal oats, micro-algae, and ceramides to give stressed-out skin a hard reset.

:quality(70):extract_cover():upscale():fill(ffffff)/2023/05/05/876/n/44344577/shopJaNERT.jpg)

Best Plumping Polyglutamic Acid

Typology Plumping Serum With Polyglutamic Acid 3% + Red Seaweed Extract ($50)

Late nights taking their toll on your skin? Lock in moisture to refresh and smooth tired, lined complexions with this lightweight serum. It sells out fast, so add to cart if you see it in stock.

:quality(70):extract_cover():upscale():fill(ffffff)/2023/05/05/876/n/44344577/shopNjqjU5.jpg)

- Beauty Explainer

Move Over, Hyaluronic Acid—Polyglutamic Acid Retains 5 Times More Moisture

If you ever suffer from dry skin, chances are, you've reached for hyaluronic acid , and for good reason. This hydrating ingredient revives dry, tight, or flaky skin . As someone with extremely dry skin no matter what I throw at it, I often wish there was something even more hydrating than hyaluronic acid .

Enter polyglutamic acid. Consider polyglutamic acid hyaluronic acid's overachieving older sister. The two ingredients are cut from the same cloth and have many of the same benefits for skin, but with a few key differences. Keep reading to find out more about polyglutamic acid.

What are the benefits of polyglutamic acid?

Just like hyaluronic acid, Polyglutamic acid is a humectant. According to Elyse Love, MD, a board-certified dermatologist, that means the ingredient draws moisture into the skin when it is paired with a moisturizer. " This leads to increased skin hydration and improvement in the appearance of dullness and fine wrinkles," she explains. "It is a great ingredient for anyone who wants extra hydration to the skin, especially those who struggle with dull and/or dehydrated skin. It plays well with almost all other skin ingredients and works well for all skin types."

Hyaluronic Acid vs Polyglutamic Acid

The biggest difference between hyaluronic acid and polyglutamic acid is polyglutamic acid's ability to retain water. " It's been shown to retain moisture up to 5000 times its weight, which is more potent than hyaluronic acid," says David Kim, MD, MS, and board-certified dermatologist. "Hyaluronic acid can retain moisture up to 1000 times its weight."

Our favorite polyglutamic acid products:

"Obagi Clinical Dark Spot Disruptor Discoloration Correcting Serum combines the hydrating effects of p olyglutamic a cid with the soothing and brightening effects of bakuchiol for a gentle, lightweight formula to improve the appearance of dark spots, dullness, and fine wrinkles," says Love.

"It's a very light and gentle essence with polyglutamic acid and ferment filtrates that is good for all skin types, especially during the summer," says Kim.

There's nothing better than a good makeup-skincare hybrid. Versed's Mood Lighting has all the skincare benefits of a serum with all the illuminating benefits of a highlighter. Polyglutamic acid is the star of the show, working to visibly plump skin.

This supercharged serum is basically a one-stop shop for good skin in a bottle. Polyglutamic acid and vitamin C are blended together for a serum that plumps while brightening.

For just $15, this gel-like serum packs a major moisturizing punch. It helps lock in moisture while also priming skin for makeup application.

If you're after bright skin, try mixing in this vitamin C–rich moisturizer. A blend of peptides, polyglutamic acid, squalane, and a double-encapsulated blend of lipids help moisturize and strenghten skin.

If you wants the benefits of retinol but have super sensitive skin, try reaching for this bakuchiol serum. Bakuchiol helps even texture and tone while polyglutamic acid plumps.

Consider this hydrating serum a triple threat. Mega moisturizers hyaluronic acid, algae extract, and polyglutamic acid are basically like a Gatorade for dehydrated skin.

Using an essence is already a great way to add a blast of hydration to skin. This one has vitamin C and polyglutamic acid to brighten and moisturize.

If you're after some serious hydration, this deeply moisturizing cream delivers. Polyglutamic acid and ceramides work in tandem with each other to hydrate and nourish the skin. Use it liberally anywhere you need a boost of moisture.

Puffy eyes and dark circles are no match for this brightening eye cream. The brand's essential moisture complex has a blend of polysaccharides, hyaluronic acid, polyglutamic acid for plump, hydrated under eyes.

Mutha's multitasking serum has vitamin C, hyaluronic acid, polyglutamic acid, and camellia oil for supremely hydrated and radiant skin.

With 12 different weights of hyaluronic acid, this cream is about as hydrating as you can imagine. Polyglutamic acid also helps hydrate, while growth factors work to nourish and restore skin.

Other hydrating products we love:

Next: Hyaluronic Acid Should Be Your Desert Island Skincare Ingredient—Here's Why

Katie Berohn is the associate beauty editor at Who What Wear. Previously, she worked as the beauty assistant for Good Housekeeping , Woman's Day, and Prevention magazines, all part of the Hearst Lifestyle Group. She graduated from the University of Colorado, Boulder, with a major in journalism and minor in technology, arts, and media, and earned her master's degree at NYU's graduate program for magazine journalism. In addition, Katie has held editorial internships at Denver Life magazine, Yoga Journal, and Cosmopolitan ; a digital editorial internship at New York magazine's The Cut ; a social good fellowship at Mashable ; and a freelance role at HelloGiggles . When she's not obsessing over the latest skincare launch or continuing her journey to smell every perfume on the planet, Katie can be found taking a hot yoga class, trying everything on the menu at New York's newest restaurant, or hanging out at a trendy wine bar with her friends.

Sponsor content created with Lululemon.

By Humaa Hussain

By Natalie Munro

Could I achieve that Parisian glow?

By Grace Lindsay

Take your pick.

By Grace Day

Glow in a bottle.

An industry icon.

From head to toe.

The underrated AHA you need to know about.

By Mica Ricketts

Take notes.

From £5 to £155.

- Contact Future's experts

- Terms and conditions

- Privacy policy

- Cookies policy

- Accessibility Statement

- Advertise with us

Who What Wear UK is part of Future plc, an international media group and leading digital publisher. Visit our corporate site . © Future Publishing Limited Quay House, The Ambury, Bath BA1 1UA. All rights reserved. England and Wales company registration number 2008885.

- Search Please fill out this field.

- Newsletters

- Sweepstakes

We independently evaluate all recommended products and services. If you click on links we provide, we may receive compensation. Learn more .

Dermatologists Say Polyglutamic Acid Is the Anti-Aging Ingredient 10 Times More Moisturizing Than Hyaluronic Acid

And these PGA-infused products will create an instant glass-skin finish.

Tamim is beauty commerce writer at InStyle, with nearly a decade of experience writing about beauty, fashion, wellness, and music.

:max_bytes(150000):strip_icc():format(webp)/tamim-alnuweiri-2000-725ca5d559e445eabd4c2f2718f11022.jpg)

In the skincare industry's current top 40, one ingredient reigns supreme — hyaluronic acid . It's a multitasking powerhouse of an ingredient you can find in any and every type of skincare product thanks to its multitude of benefits, like replenishing and retaining moisture, which helps reduce the appearance of fine lines and wrinkles, keeping the skin looking supple and smooth. But there is an under the radar anti-aging ingredient that a dermatologist refers to as a "close cousin" to HA — polyglutamic acid (PGA).

Put simply, "PGA keeps skin super dewy, hydrated and maintains the bounce or sponge-like quality of younger skin," Dr. Ava Shamban , MD, cosmetic dermatologist says. Like HA, it's a humectant but according to Dr. Shamban, "can hold 4,000 times its weight in water — 10 times more moisture than hyaluronic acid."

PGA has a relatively larger molecular size, which essentially means that it is useful for surface level, and not penetrative, hydration. Polyglutamic acid and hyaluronic acid, however, are not mutually exclusive ingredients in formulas. They are often used together because of their slightly differing properties, according to Dr. Shamban.

But the lesser-known PGA does have some specific advantages. First, PGA is an instant gratification ingredient. Dr. Shamban tells InStyle that it is more effective in diminishing the appearance of fine lines, wrinkles, and the appearance of pores. The acid's efficient hydration plumps the upper layers of your complexion , creating a quick-acting glass skin effect.

And while it doesn't penetrate the deep layers of the skin, it does prevent hyaluronidase — an enzyme responsible for breaking down the hyaluronic acid in your skin thereby accelerating aging. This is what makes it a great booster for HA skincare products.

To quickly summarize all of the science just thrown at you — PGA instantly plumps and hydrates your epidermis for a glass skin effect while also preventing the breakdown of pre-existing hyaluronic acid. It's a one-two punch that makes for a great anti-aging ingredient. If your interest is piqued, check out the products below.

Charlotte Tilbury Charlotte's Magic Serum

Part of Charlotte Tilbury's beloved Magic line, this serum combines PGA and vitamin C for an instantly plump and vibrant complexion.

Decorté Liposome Eye Cream

This eye cream instantly plumps and awakens your face thanks to the long lasting hydration effects of polyglutamic acid.

Glow Recipe Watermelon Glow Ultra-Fine Mist

Glow Recipe's Watermelon Mist is actually one of Dr. Shamban's PGA-infused products. "It combines both hyaluronic acid and polyglutamic acid for a throughout-the-day refresher to hydrate skin."

The Inkey List 3% Polyglutamic Acid

A budget-conscious choice that's perfect for dipping your toes in the hydrating waters of PGA, Dr. Shamban recommends this straightforward Inkey List serum.

Then I Met You The Giving Essence

Before you begin your skincare routine, start with this polyglutamic acid and red algae formulated essence. The combination of the two gently exfoliates dead, pore-clogging cells while hydrating the skin, creating an ideal canvas for the rest of your products.

Omorovicza Midnight Renewal Serum

Another Dr. Shamban recommendation, she says this Hungarian product is specifically for "more mature skin" thanks to ingredients such as retinol and oat lipid microalgae — the latter being protective against stress and optimizing the skin for overnight repair.

Shop More InStyle-Approved Picks

:max_bytes(150000):strip_icc():format(webp)/GettyImages-1779500227-d9e631dbe879428fb9d8448beb5eb59f.jpg)

Related Articles

- United Kingdom

Okay, What's Polyglutamic Acid?

Okay, what’s polyglutamic acid, what is polyglutamic acid , what does it do, how should i use it, what’s a good formula.

More from Skin Care

R29 original series.

I’ve Been Through 10 Bottles of This Ultra-Hydrating Serum That’s Got Me To Stop Wearing Makeup Almost Entirely—And It’s Back in Stock

Haven’t you heard? Polyglutamic acid is the buzzy hydrating skin-care hero in town that’s even more effective than hyaluronic acid. The potent active is finally getting the spotlight it deserves, and just so happens to be the key ingredient in the product I’ve been screaming about from the rooftops to anyone who will listen: FaceGym Hydrobound Daily Serum ($68). Trust me—this is one product (and ingredient) worth knowing about. Keep reading to find out more.

What is polyglutamic acid?

“Polyglutamic acid (PGA) within skincare is a biopolymer first discovered in jellyfish that prevents tissue dehydration in salt water. Nowadays it’s sourced via fermentation,” says Krupa Koestline, cosmetic chemist and founder of KKT Consultants . It’s actually found in natto, a sticky Japanese dish made from fermented soybeans (which is the same way it’s sourced for skin care).

The ingredient acts as a humectant, like hyaluronic acid, drawing in water to keep skin hydrated and maintain its moisture barrier over long periods of time. Cara Bondi , a cosmetic chemist who has worked with beauty brands like Tata Harper Skincare, Ursa Major, and Sol De Janeiro, notes that polyglutamic acid also smooths the appearance of wrinkles, increases moisture retention, softens skin, and evens skin tone.

The biggest difference between hyaluronic acid and polyglutamic acid is their molecular weight, which has an effect on their effectiveness to hydrate the skin. Polyglutamic acid molecules are larger than hyaluronic acid molecules, which means they stay on the surface of your skin to create a sort of film that locks in water. Of course, both ingredients are effective humectants (there’s a reason why HA is so beloved), but polyglutamic acid works just a little bit harder.

{{post.sponsorText}}

“Polyglutamic acid holds 4,000-5,000 times its weight in water. Hyaluronic acid is usually cited as 1,000 times its weight in water,” says Bondi. However, while polyglutamic acid is more effective, it’s a lot more expensive to source. According to derms, this is why we don’t often see the ingredient marketed. If you do, it will be more pricey than your trusted hyaluronic acid serum; around $60 - $70 dollars.

The polyglutamic acid serum that transformed my skin

The larger, 30 mL bottle is back in stock for $77. The smaller, 15 mL bottle ($45) is currently on back-order. But trust me—go with the bigger bottle. You’ll need it.

Both of these powerhouse ingredients are present in Face Gym’s Hydrobound serum, which means you’re getting a double dose of hydration. Plus, it’s got niacinamide, which means the formula offers a trifecta of skin-perfecting, nourishing, and smoothing ingredients.

The combination of polyglutamic acid and multi-molecular Ha4 (hyaluronic acid) in Hydrobound delivers hydration and helps the skin naturally produce its own hyaluronic acid, improving skin elasticity and softening fine lines. “Polyglutamic acid is ideal for those with dry or dehydrated skin,” says Kim Nichols, MD , board-certified dermatologist and founder of NicholsMD in Greenwich, CT. Hydrobound also contains a bio-lifting complex that works with niacinamide to firm skin and rebuild damaged areas of the skin barrier.

It’s hard to play favorites when you’re a beauty editor but when you go through a bottle of a specific skin-care product every month, despite having endless choices, you tend to notice. Hydrobound is so good, it’s the only product that I religiously order and simply can’t live without.

Lifetime to date, I’ve been through about 10 bottles of this serum. The first few were gifted (thank you) but then I realized couldn’t be without this precious formula ever again, so I started buying multiple at a time. I love it because it’s lightweight, and almost feels like water on your face. In addition to the longterm hydration benefits it offers, I can instantly see it quenching my skin every time I apply. In the past year I’ve been using this serum, I’ve never received more compliments on how my complexion looks. I’ve gone makeup free almost every chance I get and my skin looks and feels healthy and clear–not at all dehydrated. I give this serum a 10 out of 10, and will keep buying it until they no longer stock the shelves with it.

Loading More Posts...

The Beach Is My Happy Place—and Here Are 3 Science-Backed Reasons It Should Be Yours, Too

Your official excuse to add "OOD" (ahem, out of doors) to your cal.

4 Mistakes That Are Causing You to Waste Money on Skin-Care Serums, According to an Esthetician

These Are the Best Anti-Chafing Denim Shorts—According to Some Very Happy Reviewers

{{ successMessage }}

Please wait a moment...

- Beauty Amplified

Get to Know Polyglutamic Acid, the Hydrating Ingredient Taking Over Right Now

When we think about hydrating ingredients, acids aren’t always the first thing to come to mind. Of course, the popularity of hyaluronic acid , with its ability to hold 1000 times its weight in water and all, changed all that. But a new ingredient, polyglutamic acid—PGA for short—has entered the scene. And it’s appearing in an increasing number of hydrating skincare products. We checked in with dermatologist Karan Lal, MD, to find out more about this popular ingredient—plus, we’re sharing five PGA-infused products worth getting your hands on now.

About the Expert :

Karan Lal, MD, is a board-certified dermatologist at Schweiger Dermatology Group in Hillsborough, New Jersey.

Quick question: what is polyglutamic acid.

Despite its long name, you’ll likely be hearing more and more about this powerhouse skincare ingredient. “Polyglutamic acid is the new humectant on the block,” says Dr. Lal. And like other humectants (i.e. hyaluronic acid, glycerin , and even sugar ), it works by attracting water molecules to the skin’s surface. The name itself also helps explain what it is—”poly” means many, denoting that it’s a compound of multiple glutamic acids. Therefore, says the derm, PGA “is a larger molecule [than similar ingredients], thus it sits on top of your skin and soaks up water.”

What Are the Benefits of Polyglutamic Acid?

Three words: hydration, hydration, hydration. “It’s a phenomenal moisturizer and it gives you dewy skin,” explains Dr. Lal. In addition to being great for dry and dehydrated skin, it’s also a great addition to anti-aging products. Look for it in everything from moisturizers to serums to eye creams, though it’s especially effective in water-soluble formulations, for obvious reasons. “Because it hydrates the top of the skin, it can help soften fine lines after you apply it,” says the derm, adding that “This means it’s great as a base before applying makeup.”

Even better, polyglutamic acid has no known side effects, and can be used by pretty much everyone. “PGA is great for all skin types and skin colors,” says the derm. “It’s especially great for patients with facial eczema who feel like they can’t get enough moisturizer on their face.” Plus, because PGA is non-irritating it plays well with other active ingredients. “Because it’s not an exfoliating acid it can be used with all of your other skincare products,” reassures Dr. Lal.

How Is Polyglutamic Acid Different From Hyaluronic Acid?

Hydrating? Check. Plumping? Check. Non-irritating? Check. If PGA sounds similar to hyaluronic acid, it’s because it is. “Similar to hyaluronic acid, it soaks up a lot of water which makes it a great hydrating agent,” explains Dr. Lal. The main differences are that hyaluronic acid is naturally found in our skin, whereas polyglutamic acid isn’t (it’s sourced from Japanese fermented soybeans called natto). Also, the molecule is much larger. “Polyglutamic acid retains four times more moisture than hyaluronic acid,” says the expert. That said, the two ingredients are often seen together on labels to double up on hydration benefits.

The Best Polyglutamic Products to Try Now

1. the inkey list polyglutamic acid.

This silky serum puts the focus on the PGA, featuring a 3% concentration of the ingredient. It can be applied both in the morning and at night for a boost of hydration, and creates a bouncy, smooth surface for makeup, or your next skincare steps.

2. CHARLOTTE TILBURY Magic Serum Crystal Elixir

Mixing the hydrating power of PGA with the brightening benefits of vitamin C? That’s the genius of Charlotte Tilbury. The formula boosts elasticity, and skin looks glowy and smoother with each use and over time.

3. FACE GYM Hydro-Bound Hydrating Face Serum

This hydrating serum blends the powers of PGA and multiple weights of hyaluronic acid, making it a great layer in any skincare routine, especially for dry skin. Plus, it has niacinamide to strengthen skin and leave it more even toned, too.

4. FARMACY Daily Greens Silicone-Free + Oil-Free Gel Moisturizer

Another great thing about polyglutamic acid? It’s great in oil-free formulas, such as this moisturizer. Also made with hyaluronic acid, as well as clarifying moringa, willowherb, and papaya, it’s ultra-hydrating yet lightweight and won’t clog pores.

5. VERSED Mood Lighting Lumizing Glow Drops

We love any product that offers a one-two punch, and this hydrating highlighting fluid both adds a subtle glow as it plumps skin with PGA and antioxidant-packed blackberry extract. Wear it alone or mixed with foundation, depending on how much radiance you’re going for.

Want hydrating skincare—and so much more—delivered each month with the IPSY Glam Bag? Take our Beauty Quiz now to get started. Already an Ipster? Refer your friends to earn points, which you can use toward products. Either way, don’t forget to check us out on Instagram and Twitter @IPSY.

Like this article? Share it with your friends by clicking the icons below!

More Stories

- BEST SELLERS

- DAILY DEALS

- SHOP BY PRODUCT Shop All Eyes Exfoliator Cleanser Mask Facial Serums Facial Oil Facial Moisturiser SPF Body Creams Shampoo Conditioner

- SHOP BY CONCERN Ageing, fine lines and wrinkles Dull Skin Dry Skin Loss Of Elasticity

TAKE THE SKINCARE QUIZ

- Bundles & Gifts SHOP ALL Retinol Moisturise & Sooth Kit Caviar Anti-Aging Starter Kit Collagen Starter Kit Youth Series Green Caviar Hydrating Gift Set Youth Series Collagen Acne Prone Gift Set Youth Series Green Caviar Essentials Full Set Youth Series Collagen Tone & Flex Kit Youth Series Hyaluronic Acid Smooth & Condition Kit

YOUTH SERIES WELCOME KIT

- Beauty Tips

- Daily Deals

- Discount Codes

Your cart is empty

20 products

Molecular dynamics simulation and performance verification of γ-polyglutamic acid/cold water-soluble starch film formation and permeability

- ORIGINAL PAPER

- Open access

- Published: 26 March 2024

Cite this article

You have full access to this open access article

- Zuolong Yu 1 ,

- Yao Chen 2 ,

- Yongfei Chen 3 ,

- Yunxiao Wei 1 ,

- Changchun Fu 1 ,

- Dan Liu 1 ,

- Keshavan Niranjan 4 &

- Chao Han 1

431 Accesses

Explore all metrics

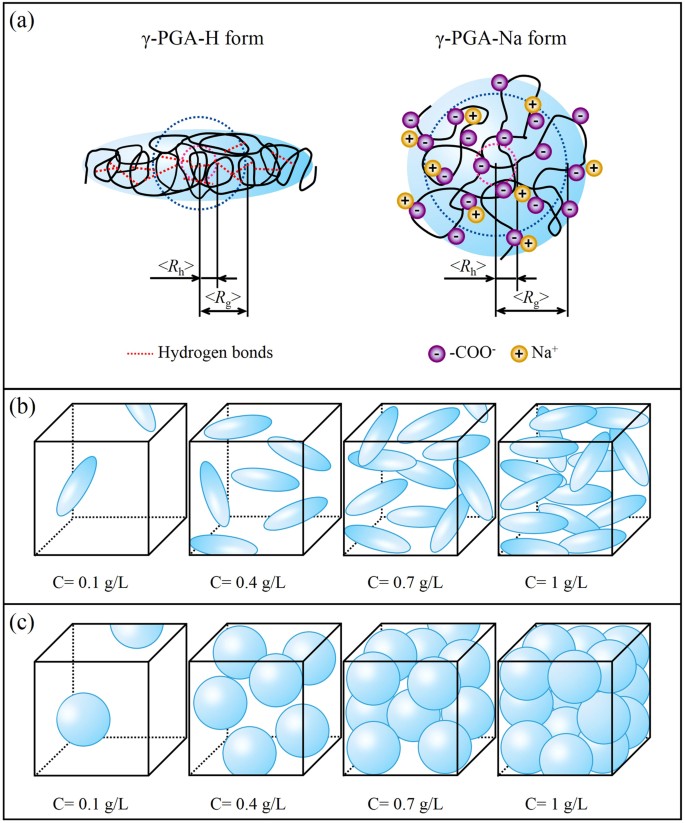

Six types of γ-polyglutamic acid (γ-PGA)/cold water-soluble starch (St) composite film models were constructed using molecular dynamics simulation, and their properties were investigated and compared with the corresponding experimental values. The compatibility between the composite film components was analyzed using the radial distribution function and mean square displacement (MSD). The hydrogen-bond number and bond energy were used to track the film-formation process. The mechanical property data of the films were extracted, and MSD was used to analyze the permeability of the film to carbon dioxide, oxygen, water vapor, and carbon-16 saturated fatty acids. Finally, the simulated values of mechanical properties and permeability were compared with the experimental values. The results demonstrated that γ-PGA is well compatible with St. The intramolecular and intermolecular hydrogen bonds of γ-PGA and St did not change considerably during the film-formation process. The simulated values of the mechanical properties exhibited a similar trend as the experimental values; however, in terms of permeability, a difference was observed between the initial values of the simulated design and actual material parameters, as well as the complexity of the experiment.

Similar content being viewed by others

Analysis and Modeling of Mechanical and Barrier Properties of Arracacha Starch-Chitosan Composite Biodegradable Films

Omar R. Garcia, Magda I. Pinzón & Cristian C. Villa

Effects of various nanomaterials on the properties of starch/poly(vinyl alcohol) composite films formed by blow extrusion process

Wentao Wang, Hui Zhang, … Haizhou Dong

Preparation and Characterization of Hybrid Composite Film Based on Synthetic and Natural Materials

Waham Ashaier Laftah & Wan Aizan Wan Abdul Rahman

Avoid common mistakes on your manuscript.

Introduction

Starch, which is one of the most abundant polysaccharides on Earth, can be converted into different biobased materials through physical and chemical modifications, e.g., pharmaceutical excipients [ 1 , 2 ] and packaging plastics [ 3 , 4 ]. These materials can be applied in pharmaceutical [ 5 ] and environmental industries, and if the materials meet people’s dietary needs, they can be used in the food industry [ 6 , 7 ]. The physicochemical properties of starch differ according to its amylose and amylopectin content, and the solubility characteristics of starch in water differ according to the number of glucose units. Raw starch cannot be dissolved in water; it can only form a suspension or colloid. When the raw starch is processed and its molecular weight drops to thousands to tens or hundreds of thousands, it can be dissolved in hot water (referred to as soluble starch) [ 8 , 9 ] or cold water (referred to as cold water-soluble starch) [ 8 , 9 , 10 , 11 , 12 ]. Studies have shown that starch-based products obtained by different treatment methods have a wide application range [ 13 , 14 ].

Industrial γ-polyglutamic acid (γ-PGA) products can be obtained using the fermentation methods of different genetically engineered strains [ 15 , 16 ]. After separation and purification, γ-PGA can be used to prepare environmentally compatible products, e.g., hydrogels, nanoparticles, and packaging films [ 17 , 18 , 19 ]. γ-PGA with different molecular weights can be obtained by modifying genetically engineered bacteria and changing the fermentation conditions, which expand its applicability and enhance its application value [ 9 , 20 , 21 ].

Starch-based films are relatively inexpensive and environmentally friendly. Their poor mechanical and nonthermoplastic properties can be modified and improved via blending or copolymerization to enhance their application. In addition, the known antibacterial properties and intelligent manifestations of these films can broaden the application range of starch in the packaging field [ 22 , 23 , 24 , 25 ]. γ-PGA films are also receiving increased research interest in food packaging [ 19 ], medical materials [ 26 ], and heavy-metal adsorption [ 27 ] applications.

The molecular simulation technology developed in recent years can be used to investigate the interactions and mechanisms of various components at the molecular level, predict material properties, reduce experimental costs and time, and accelerate the development of new materials [ 28 , 29 ]. The compatibility [ 30 ], glass transition temperature [ 31 ], mechanical properties [ 32 ], and gas diffusion [ 33 ] of blend films can be effectively predicted using molecular dynamics (MD) techniques. Researchers have used MD for designing the preparation methods and determining the properties of biobased macromolecules, e.g., polysaccharides and proteins [ 34 , 35 ]. In this study, the complex starch molecule was simplified into cold water-soluble starch to prepare γ-PGA blends and obtain composite films with different mass ratios. The compatibility, mechanical properties, and permeability of the composite films were estimated via molecular simulation. The experimental results agreed with the simulated values, and comprehensive data were obtained from micro and macro perspectives. Meanwhile, it provided a reference for molecular dynamics simulation of biological macromolecules.

Methodology

Model and simulation methodology, modeling and relaxation.

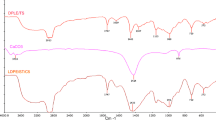

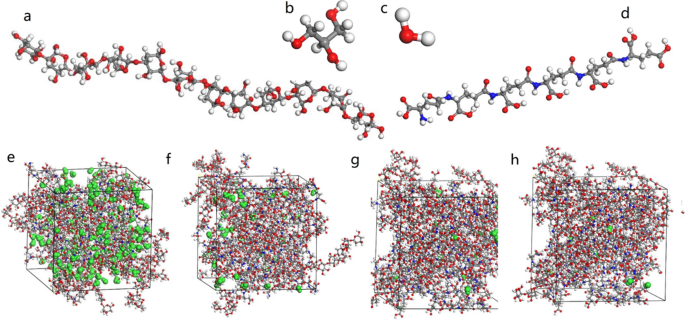

In this study, first, molecular structures of γ-PGA, starch, and glycerol were constructed through the modeling function of Materials Studio 7.0 (Figs. 1 a, b, and d), and the degree of polymerization of γ-PGA and starch molecules was 10. Then, three types of molecular chains of the amorphous system were constructed using the Amorphous Cell module. The mass ratios of γ-PGA and starch in the amorphous system were 10:0, 8:2, 6:4, 4:6, 2:8, and 0:10, and the mass of glycerol was 10% of the total mass. (The six composite films are referred to as P10S0, P8S2, P6S4, P4S6, P2S8, and P0S10, respectively.) To preserve appropriate space between the molecules in the subsequent relaxation process of the system, the initial density of the model was set to 0.8 g/cm 3 , the summation method of electrostatic energy in nonbonding interaction energy was group-based, the summation method of van der Waals interaction energy was atom-based, and the truncation radius was 12.5 Å. Further, the COMPASSII force field was used, and the atomic charge was automatically allocated to the force field. After the model was constructed, the structure was optimized using the Forcite Plus module in Materials Studio. The optimization method was efficient enough to obtain a lower energy system.

Simulation model of low energy monomer molecules and their blends with different water content: a starch; b glycerin; c water; d γ-polyglutamic acid; e , f , g , and h blend systems containing 100, 20, 10, and 1 g of water, respectively

Finally, the kinetic method was used to fully relax the model. To quickly eliminate the internal stress in the system, the total simulation time was set to 300 ps, and the system comprised a constant number of atoms at normal pressure and temperature (NPT). The pressure was 1 atm, and the temperature was 600 K. After relaxation, an NPT system was used in the model, where the temperature was 300 K, the pressure was 1 atm, the simulation time was 3 ns, and the time step of the two dynamics was 1 fs. A single frame was output every 1000 steps, the force field was COMPASSII, and the summation method of electrostatic energy was group-based. In addition, the summation method of van der Waals interaction energy was atom-based, and the truncation radius was 18.5 Å.

Film-formation mechanism

The P6S4 sample was selected as the simulation object. The Amorphous Cell tool in Materials Studio was used to set up four types of film liquids or film model structures with different water contents (100, 20, 10, and 1 g), from the initial film liquid to dry film-formation process. The MD parameters of the film-formation process were then analyzed. Note that the conditions of the MD simulation were the same as those described in Sect. " Modeling and relaxation ". Particularly, the model size ranges from 30 to 40 Å. The systems characterized by different water contents (obtained through experiments) are investigated from a simulation perspective. The simulation method indirectly represents the water content based on a specific number of water molecules and utilizes a dominant solution model. The temperature was changed from normal temperature to 333 K, the total simulation time was 1 ns, the time step was 1 fs, and the deterministic Nosé–Hoover Langevin algorithm was the temperature-control method. After the dynamics were completed, the trajectory file was analyzed to obtain the total number of hydrogen bonds in each system. Here, to further investigate the contribution of each component to the hydrogen bonds, the number of hydrogen bonds between each component was also extracted. In this study, the maximum length of the hydrogen bond was set to 2.5 Å and the minimum angle of the hydrogen bond was set to 90°.

Mechanical properties

The tensile mechanical properties of the systems were investigated. Equilibrium calculations for MD were conducted across all systems. Subsequently, 100 frames were selected from the model at the equilibrium stage to calculate the mechanical properties. The calculation method involved altering the strain of the model and calculating the stress of the system. Six strains, comprising three stretches and three compressions, were calculated for each structure, with a maximum deformation of 0.5%. In addition, the stress–strain curve was obtained by submitting the stress and strain data during the stretching process.

- Permeability

The permeation effect of different molecules in six composite film systems was investigated. During the investigation, oxygen, carbon dioxide (CO 2 ), water, and carbon-16 saturated fatty acid molecules were separately added to the model. The MD simulation process was the same as that described in Sect. " Modeling and relaxation ". In the diffusion–penetration–simulation process, the dynamics were integrated into microcanonical ensemble (NVT), the time step was 1 fs, and the total simulation time was 1000 ps.

Experimental verification

To validate the guiding significance of the simulation method, the corresponding simulation blending films with different proportions were prepared. The simulation and experimental results regarding rheological properties, mechanical properties, and permeability of the membrane toward four types of substances were compared.

Film preparation

The films were prepared using γ-PGA (70 KDa) (Nanjing Shineking Biotech, Co., Nanjing, China) and starch (96–100% solubility in water) (Shanghai Aladdin Biochemical Technology Co., Ltd., Shanghai, China) as the main substrates and glycerol as the additive, and the formula was as follows in Sect. " Modeling and relaxation ". In the specific experimental methods, the P6S4 sample was taken as an example. Here, 4 g of starch and a certain amount of water were stirred evenly and poured into a three-neck flask and then gelatinized by heating at 85 °C for 30 min. In a separate flask, 6 g of γ-PGA, 1 g of glycerol (Sinopharm Group Chemical Reagent Co. Ltd., Shanghai, China), and 100 mL of water were stirred and dissolved. This mixture was then added to the three-neck flask containing gelatinized starch and stirred for 10 min. After degassing, the resulting film liquid was cast on a glass plate and dried in an oven at 60 ℃ to form a film (with a moisture content of ~ 10% of the total mass). The mechanical properties and permeability values were tested after 48 h.

The storage modulus and shear rate curves of the film liquids were determined using a rheometer (MCR 102, Anton-Paar, Shanghai, China). The measurements were performed at a constant temperature of 80 °C using a conical plate with a diameter of 50 mm and an angle of 1° using the flow curve measurement mode. The shear rate was considered a variable with a range of 0.1–100 s −1 , the mode was linear scan, and 50 variable points were selected.

The sample was cut into strips with a length of 5 cm and a width of 0.5 cm. The tensile modulus (T) of the films was measured (TA.XT Plus, Stable Micro System, London, UK) along the vertical and horizontal directions using three strips. In total, six parallel samples were measured. The standard distance was 50 mm, and the sampling speed was 100 mm/min.

A strong alkali absorption method was used to determine CO 2 permeability [ 36 , 37 ]. A weighing bottle containing 200 mL of a 1-N KOH solution was sealed with the film to be tested and placed in a desiccator with a 10% relative humidity (RH) saturated salt solution. The system was balanced in a nitrogen (N 2 ) environment for 24 h, and then N 2 was replaced with CO 2 to maintain the partial pressure of CO 2 outside the film at 101 kPa. CO 2 was absorbed by the KOH solution through the film. The absorption time and weight gain of the weighing bottle were recorded, and the CO 2 transmittance was calculated as follows.

where \({\text{P}}_{{{\text{CO}}_{2} }}\) is the CO 2 permeation rate of the film (mg/(cm 2 ·d)), Δm is the mass of CO 2 absorbed by the KOH solution (mg), d is the number of days, and S is the effective area of the film (cm 2 ).

GB/T 16928–1997 and the ASTM material moisture permeability test method with slight modifications were used to determine water vapor permeability (WVP). In the test, 50 g of anhydrous calcium chloride (particle size = 2 mm) was placed in a 100-mL beaker at 25 °C. After measuring the thickness of the film, the mouth of the beaker was sealed with melted paraffin and placed in a desiccator at 100% RH. The sample bottles were removed from the desiccator and weighed every 24 h. Three parallel tests were conducted, and the bottles were measured continuously for one week. The results were calculated according to a process reported in the literature [ 38 ].

Unsaturated fat absorption method was used to determine oxygen permeability [ 36 , 37 ]. A 50-mL beaker containing 20 mL of oleic acid was sealed with the film to be tested and placed in a desiccator with a 10% RH saturated salt solution. The system was balanced under N 2 atmosphere for 24 h, and then, N 2 was replaced with O 2 to maintain the O 2 partial pressure outside the film at 101 kPa. O 2 was consumed via the oxidation of vegetable oil through the film. The weight gain of the beaker was recorded at intervals, and the O 2 penetration was calculated as follows:

where \({\text{P}}_{{{\text{O}}_{2} }}\) is the O 2 permeation rate of the film (mg/(cm 2 ·d)) and Δm is the mass of O 2 absorbed by oleic acid (mg).

To evaluate the vegetable oil permeability (P oil ) [ 39 ], 5 mL of vegetable oil was poured into a test tube and sealed with the film. The test tube was placed upside down on filter paper for one week. The filter paper was weighed every 24 h to calculate the P oil of the samples.

Statistical analysis

Note that the data from the experiments are expressed as the mean ± standard deviation. The statistical differences were analyzed according to variance and LSD analysis using the SPSS software (SPSS Inc., Chicago, Illinois, USA). In this evaluation, P < 0.05 was considered statistically significant.

Results and discussion

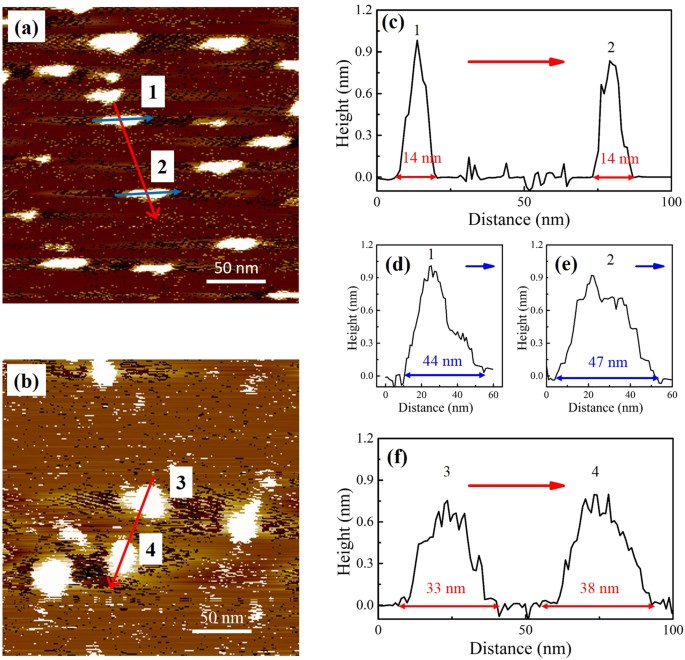

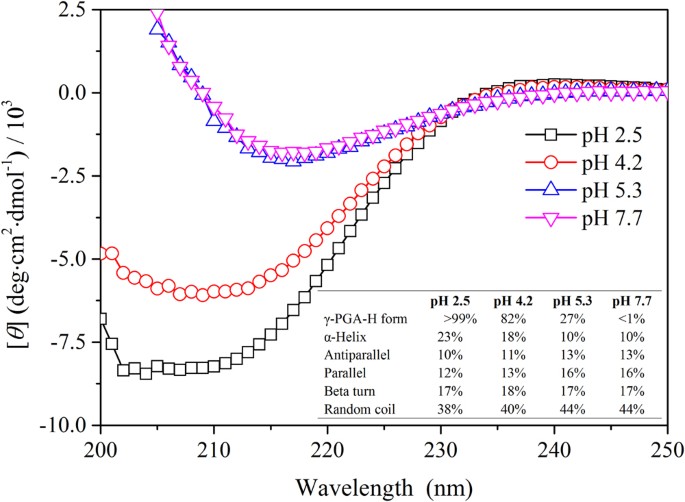

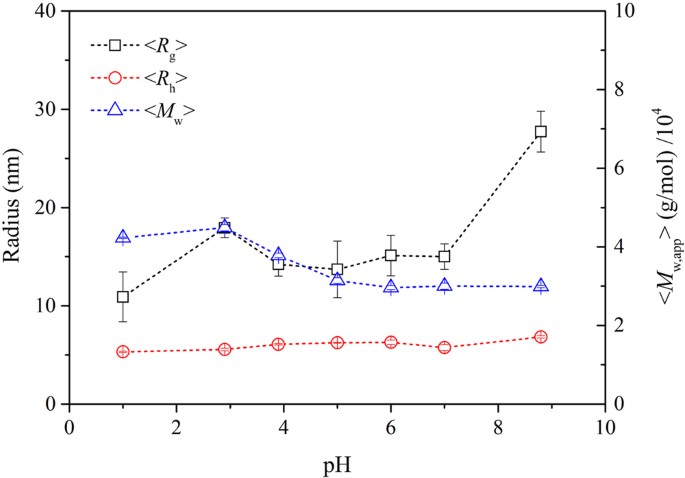

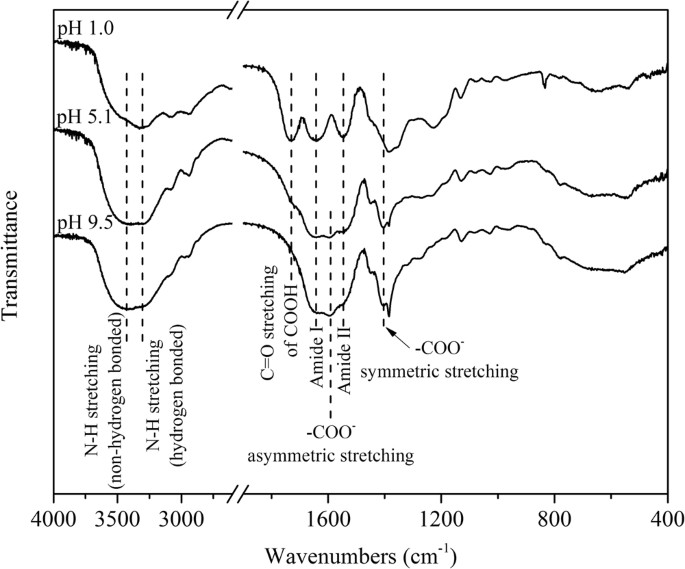

Equilibrium configuration.

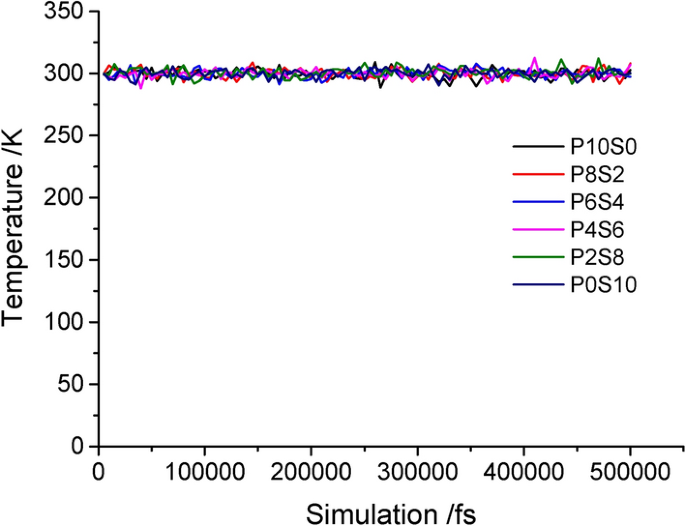

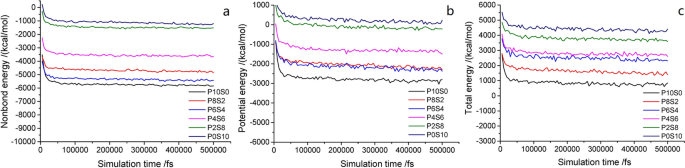

Two criteria were used to distinguish the MD simulations to achieve equilibrium: (1) temperature fluctuation < 10 °C and (2) energy fluctuation < 100 fs. Note that these criteria must be constant or fluctuate (increase or decrease) slightly along a constant value. Generally, the system is considered to have reached equilibrium when the temperature and energy fluctuations are between 5 and 10% [ 40 ]. The temperature change is minor in the simulation of the composite film model (Fig. 2 ), and the energy change is shown in Fig. 3 . At the beginning of the MD simulation, the fluctuation gradually weakened within 10–15 ps (10000–15000 fs), and the energy increased gradually. Under the action of shear force, the molecular chain untangled, and the molecules broke free from the binding, resulting in an increase in the energy of the molecular system. Then, it stabilized quickly to a constant value. These results demonstrate that the system reached a thermodynamic equilibrium structure, and then, the energy and instantaneous temperature of the system fluctuated slowly around the equilibrium value, forming a relatively stable curve according to the equilibrium criterion. This indicates that all the mixed systems reached equilibrium via MD simulation.

Temperature curves of composite films with simulation time

Energy curves of composite films with simulation time: a nonbond energy; b potential energy; and c total energy

Compatibility

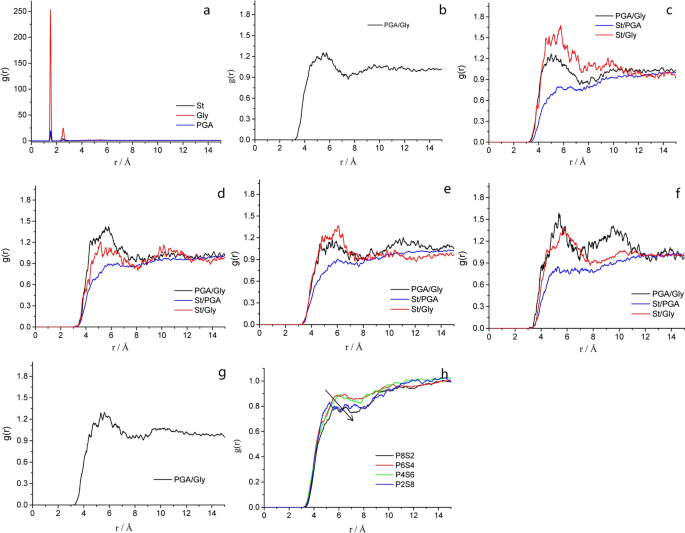

The radial distribution function (g(r)) is performed on an atom as a characteristic physical quantity that reflects the microstructure of materials. It represents the ratio of the probability density of a molecule to the probability density of random distribution at distance r around another molecule. Thus, a larger g(r) value indicates better compatibility of the blend system. The intermolecular g(r) is used to reveal the interaction mode and nature between nonbonded atoms. Note that the hydrogen-bond interaction range is 2.6–3.1 Å, and the van der Waals interaction range is 3.1–5.0 Å [ 41 ].

Figure 4 (a) shows the g(r) values of the separate γ-PGA, St, and glycerol molecules. This figure shows that none of these three pure substances exhibits a strong peak at > 3 Å, verifying that the constructed molecular structure is amorphous [ 42 ]. However, no peak is observed, and the g(r) value approaches 1 at radial distances of > 4 Å, proving that the blend system has amorphous characteristics [ 43 ]. As shown in Figs. 4 b–g, the g(r) values of all the blends peak at ~ 5 Å. Thus, the main mode of interaction between the blends is considered as the van der Waals force. By comparing the g(r) values of the C–C bond between the γ-PGA/St molecules (Fig. 4 h), we found that the peak-height order of the blends was as follows: P6S4 > P4S6 > P2S8 > P8S2. This trend indicates that the blend system exhibits good compatibility, and when the quality of the two substances is equivalent, the compatibility is better. In addition, by comparing the nonbond energies of their respective systems (Fig. 3 a), the bonding energies of the blends are observed to follow the order of P6S4 > P8S2 > P4S6 > P2S8.

Radial distribution function (RDF) of C–C atoms in composite films and monomers: a RDF of γ-PGA, St, and Gly; b – g : RDF between molecules in P10S0, P8S2, P6S4, P4S6, P2S8, and P0S10, respectively; and h RDF comparison of γ-PGA/St in composite films

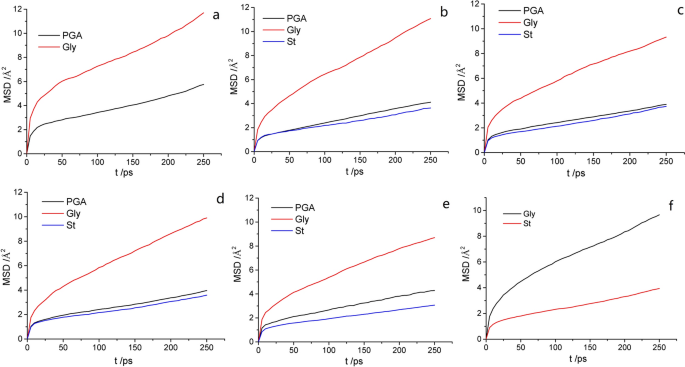

In this study, the mean square displacement (MSD) was considered to characterize the thermal motion displacement of the γ-PGA, St, and glycerol chains. Therefore, it was used to explore the mutual influence of motion ability in the films; a larger MSD value indicates a more intense thermal motion of molecules. The thermal motion of the glycerol molecules was the most intense, followed by γ-PGA and then St (Fig. 5 and Table 1 ). A comparison of different composite films indicates that the thermal motion of γ-PGA and St molecular chains was the most intense in P10S0 and P0S10. In the other composite films, the movements of the γ-PGA molecular chains were more intense than those of St, and the change trend of γ-PGA and St was opposite. These findings indicate that the movement ability of the molecular chains in the mixing system was affected by the change in the blending ratio. In the composite films with different mixing ratios, the force on the molecular chain of the system differed. The change in the mass ratio of γ-PGA/St can cause considerable changes in the secondary bond force, e.g., the hydrogen-bond force, affecting the spatial structure of the molecule and in turn affecting the movement activity of the molecule.

MSD of different molecules in composite films: a P10S0; b P8S2; c P6S4; d P4S6; e P2S8; and f P0S10

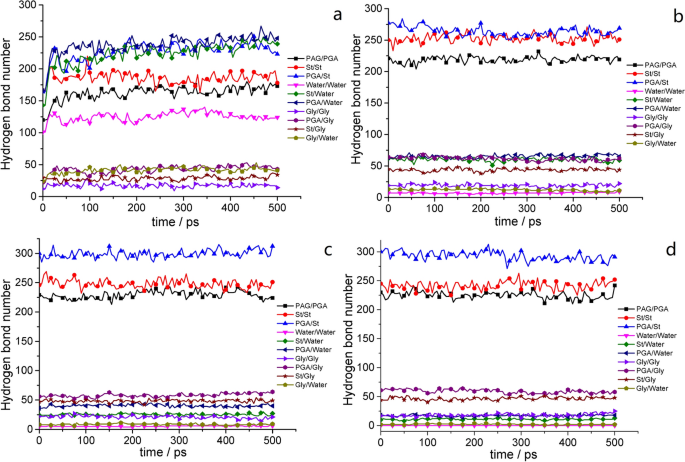

Film processing

Using P6S4 as an example, the hydrogen bonds within and between each molecule under the simulated conditions are shown in Fig. 6 . When various substances reached equilibrium after addition (Fig. 6 a), the numbers of hydrogen bonds between γ-PGA and water, St and water, and γ-PGA and St were the highest at approximately 250, 241, and 228, respectively. The numbers of intramolecular hydrogen bonds in St, γ-PGA, and water molecules were approximately 182, 171, and 123, respectively. In addition, the number of hydrogen bonds formed by glycerol was consistently the lowest. With the evaporation of water, the concentration of γ-PGA and St and the probability of their contact increased. The number of hydrogen bonds within and between the molecules increased gradually (Fig. 6 b), accounting for the majority of their total number of hydrogen bonds. The hydrogen bond between γ-PGA and St was the most evident, indicating that PGA and St can be mixed evenly and are well compatible in the film-formation process. The secondary bonds represented by hydrogen bonds between PGA and St exhibit microscopic changes. Table 2 shows that the changes in bond energy (i.e., the bond stretching energy (E bond ), bond angle bending energy (E agle ), dihedral angle torsion energy (E torsion ), and inversion energy (E inversion )) of the four composite films during the film-formation process were not significant because these processes were unaffected by external forces. Considerable changes occurred in the nonbonding energy (i.e., the van der Waals interaction energy (E vdw ), electrostatic energy (E coulomb ), and hydrogen bonding energy (E hbond )). Although the reduction of water mass was one factor, the increased interaction between γ-PGA and St decreased the reduction rate of the nonbond energy.

Number of intermolecular and intramolecular hydrogen bonds in film liquids or films with different water content: a 100; b 20; c 10; and d 1 g

The elastic modulus (E), shear modulus (G), and bulk modulus (K) are used to indicate the rigidity of the material under different force conditions. Note that the elastoplastic properties of a material are associated with E, and the hardness and tensile strength (T) are proportional to G. A positive Cauchy pressure value indicates good ductility of the material, whereas a higher value indicates better ductility of the system [ 44 ].

The mechanical properties of γ-PGA, St, and their composite films at four proportions obtained through MD simulation calculations are listed in Table 3 , including the E, K, G, and Poisson’s ratio (ν; the ratio of the transverse strain to the longitudinal strain) values. The values of the elastic constants of the C 11 , C 22 , C 33 , C 44 , C 55 , and C 66 groups, as well as the C 12 , C 13 , and C 23 groups, were similar, indicating that γ-PGA and St had good solubility. The ν value of the composite films was ~ 0.28, and the ν value of plastics is typically between 0.2 and 0.4, indicating that the mixed system exhibits some properties of plastics [ 45 ]. The Cauchy pressure values (C 12 –C 44 ) of various films were all positive, indicating that the composite films exhibit toughness. The Cauchy pressure values of the P0S10 and P10S0 samples were lower than those of the blend films, indicating that the ductility of the single principal component was poorer than that of the composite principal component and the brittleness was stronger. In addition, depending on the proportion of the components, the number of hydrogen bonds formed by the composite film varied. We found that the P4S6 sample exhibited the highest K value, the P0S10 sample showed the highest G value, and the P2S8 sample demonstrated the highest Young’s modulus (Y) value.

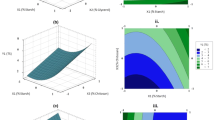

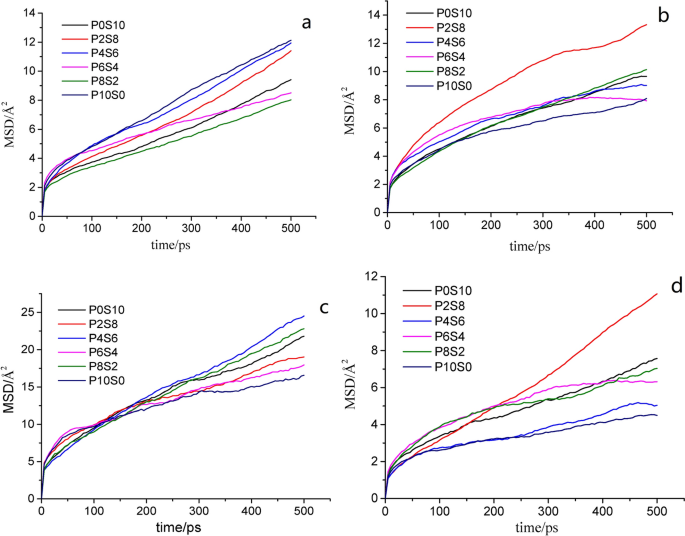

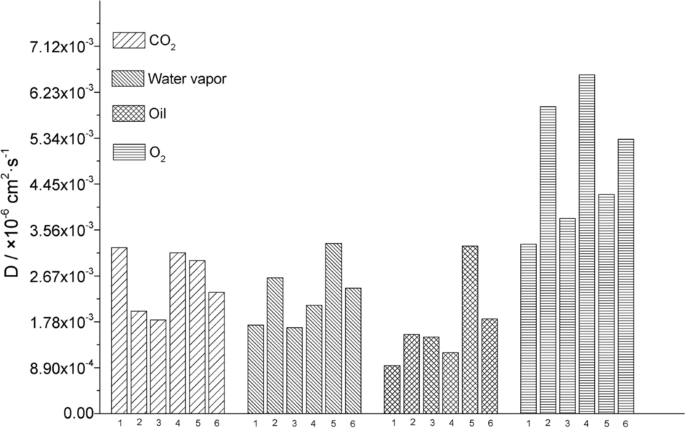

According to the MSD slope, the ability of gas to escape from the interface can be determined [ 46 ]. Figures 7 a–d shows that the diffusion of CO 2 , water vapor, O 2 , and vegetable oil in the composite films did not exhibit regular changes. The MSD of gas diffusion can also be converted into the diffusion coefficient to illustrate the molecular permeability (Fig. 8 ) [ 47 ]. The P10S0 sample exhibited the highest \({\text{P}}_{{{\text{CO}}_{2} }}\) . The P2S8 sample exhibited the highest WVP, and the P2S8 sample demonstrated the highest P oil . The P10S0 sample demonstrated the lowest \({\text{P}}_{{{\text{O}}_{2} }}\) . Note that the small molecules exhibited jumping diffusion in the polymer films, which was affected by the intermolecular force of the film. The small molecules were confined in the polymer film holes and caused small local vibrations most of the time. In addition, with the continuous movement of the polymer chain end, small molecules could jump from one hole to another [ 48 , 49 ]. The difference in the energy barrier, electrostatic interaction, and free volume fraction on the molecular chains of the membranes resulted in the difference in the diffusion coefficient of the gas through the films [ 50 ].

Permeability of composite films to four substances: a CO 2 , b water vapor, c O 2 , and d oil

Diffusion coefficients of composite films to four substances: (1) P10S0, (2) P8S2, (3) P6S4, (4) P4S6, (5) P2S8, and (6) P0S10

Experimental data

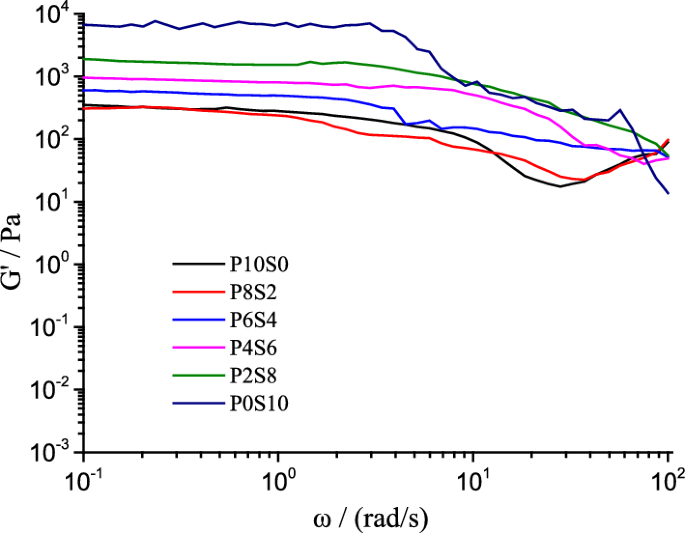

The P0S10 sample exhibited the highest storage modulus (G′) (Fig. 9 ), and with an increasing mass ratio of γ-PGA, the G′ of the composite film liquid decreased gradually, and shear thinning occurred. We found that the G′ values of the P8S2 and P10S0 samples were similar. The variation trend of the G′ values was similar to that observed for the E values. Owing to the proportional relationship between G and G′, they exhibited the same variation pattern as the simulated G values (Table 3 ). As the mass ratio of St increased, the T initially decreased and then increased, which is closely related to the molecular interaction between γ-PGA and St, as well as their molecular weights.

Storage modulus of composite film liquids

The experimental data validation for permeability (Table 4 ) showed that as the mass ratio of St increased, P2S8 exhibited the highest \({\text{P}}_{{{\text{CO}}_{2} }}\) , which was equivalent to that of P4S6 and consistent with the simulation results. However, the WVP of P0S10 was much lower than that of the other composite films; similarly, the data for \({\text{P}}_{{{\text{O}}_{2} }}\) and P oil were not consistent with the simulated values. In the simulation design, the molecular weights of the two macromolecular substances were considered to be close to the weight of only 10 monomers, while in the experiment, the molecular weight of γ-PGA was 70 KDa and the molecular weight of St was 100–200 glucose units. Thus, the difference between the simulated and experimental values was significant.

In this study, six mass ratios of γ-PGA/St composite films were simulated using MD. First, the energy-difference relationship of each composite film was compared when they reached their steady states. Owing to the secondary bond interaction between γ-PGA and St, their energy states changed in different ways. The solubility of γ-PGA and St was investigated based on their g(r) and MSD values, and the results demonstrated good compatibility. According to the film-formation process of the P6S4 sample, in the absence of an external force, the hydrogen-bond interaction between γ-PGA and St in the composite system was always the maximum with decreasing water mass. A comparison of the simulated and experimental values corresponding to the mechanical properties revealed similar variation trends between these values, indicating that the simulation method can be used for reference. However, when comparing the simulation and experimental values of permeability, the experimental settings for real substances could not be achieved due to the limitations of the simulation software conditions; therefore, the simulation values can only serve as guidance to a certain extent.

Data Availability

The data used in this study are confidential.

Labelle MA, Ispas-Szabo P, Tajer S, Xiao Y, Barbeau B, Mateescu MA (2023) Anionic and ampholytic high-amylose starch derivatives as excipients for pharmaceutical and biopharmaceutical applications: structure-properties correlations. Pharmaceutics 15:834

Article CAS PubMed PubMed Central Google Scholar

Kalita P, Ahmed AB, Sen S, Chakraborty R (2023) Citric acid esterified Glutinous Assam bora rice starch enhances disintegration and dissolution efficiency of model drug. Int J Biol Macromol 227:424–436

Article CAS PubMed Google Scholar

Rahardiyan D, Moko EM, Tan JS, Lee CK (2023) Thermoplastic starch (TPS) bioplastic, the green solution for single-use petroleum plastic food packaging—A review. Enzyme Microb Tech 168:110260

Article CAS Google Scholar

Siqueira LDV, Arias CILF, Maniglia BC, Tadini CC (2021) Starch-based biodegradable plastics: methods of production, challenges and future perspectives. Curr Opin Food Sci 38:122–130

Article Google Scholar

Saraf P, Movaghar MA, Montazer M, Rad MM (2023) Bio and photoactive starch/MnO 2 and starch/MnO 2 /cotton hydrogel nanocomposite. Int J Biol Macromol 193:681–692

Asharuddin SM, Othman N, Altowayti WAH, Bakar NA, Hassan A (2021) Recent advancement in starch modification and its application as water treatment agent. Environ Technol Inno 23:101637

Wang JP, Yuan SJ, Wang Y, Yu HQ (2013) Synthesis, characterization and application of a novel starch-based flocculant with high flocculation and dewatering properties. Water Res 47:2643–2648

Kusunoki K, Kawakami K, Shiraishi F, Kato K, Kai M (1982) A kinetic expression for hydrolysis of soluble starch by glucoamylase. Biotechnol Bioeng 24:347–354

Aboubacar A, Hamaker BR (2000) Low molecular weight soluble starch and its relationship with sorghum couscous stickiness. J Cereal Sci 31:119–126

Ma WP, Robyt JF (1987) Preparation and characterization of soluble starches having different molecular sizes and composition, by acid hydrolysis in different alcohols. Carbohyd Res 166:283–297

Jivan MJ, Yarmand M, Madadlou A (2004) Preparation of cold water-soluble potato starch and its characterization. J Food Sci Tech Mys 51:601–605

Choi YJ, Baik MY, Kim BY (2017) Characteristics of granular cold-water-soluble potato starch treated with alcohol and alkali. Food Sci Biotechnol 26:1263–1270

Anwar M, Birch EJ, Ding Y, Bekhit AED (2022) Water-soluble non-starch polysaccharides of root and tuber crops: extraction, characteristics, properties, bioactivities, and applications. Crit Rev Food Sci 62:2309–2341

Pascu B, Negrea A, Ciopec M, Duteanu N, Negrea P, Nemeş NS, Seiman C, Marian E, Micle O (2021) A green, simple and facile way to synthesize silver nanoparticles using soluble starch. ph studies and antimicrobial applications. Materials 14:4765

Yokoigawa K, Sato M, Soda K (2006) Simple improvement in freeze-tolerance of bakers’ yeast with poly-gamma-glutamate. J Biosci Bioeng 102:215–219

Xu J, Chen SW, Yu ZN (2005) Optimization of process parameters for poly gamma-glutamate production under solid state fermentation from Bacillus subtilis CCTCC202048. Process Biochem 40:3075–3081

Kim MH, Lee JN, Lee J, Lee H, Park WH (2020) Enzymatically cross-linked poly (gamma-glutamic acid) hydrogel with enhanced tissue adhesive property. ACS Biomater Sci Eng 6:3103–3113

Ikeda M, Akagi T, Yasuoka T, Nagao M, Akashi M (2008) Characterization and analytical development for amphiphilic poly (gamma-glutamic acid) as raw material of nanoparticle adjuvants. J Pharmaceut Biomed 150:460–468

Yu ZL, Wei YX, Fu CC, Sablani SS, Huang ZE, Han C, Li DN, Sun ZJ, Qin HZ (2023) Antimicrobial activity of gamma-poly (glutamic acid), a preservative coating for cherries. Colloid Surfaces B 225:113272

Sha Y, Zhang Y, Qiu Y, Xu Z, Li S, Feng X, Wang M, Xu H (2019) Efficient biosynthesis of low-molecular-weight poly-gamma-glutamic acid by stable overexpression of pgds hydrolase in bacillus amyloliquefaciens nb. J Agric Food Chem 67:282–290

Poo H, Park C, Kwak MS, Choi DY, Hong SP, Lee IH, Lim YT, Choi YK, Bae SR, Uyama H, Kim CJ, Sung MH (2010) New biological functions and applications of high-molecular-mass poly-gamma-glutamic acid. Chem Biodivers 7:1555–1562

He Y, Kong W, Wang W, Liu T, Yu L, Gong Q, Gao J (2012) Modified natural halloysite/potato starch composite films. Carbohyd Polym 87:2706–2711

Zhou P, Luo Y, Lv Z, Sun X, Zhang X (2021) Melt-processed poly (vinyl alcohol)/corn starch/nanocellulose composites with improved mechanical properties. Int J Biol Macromol 183:1903–1910

Yuan YL, Chen HY (2021) Preparation and characterization of a biodegradable starch-based antibacterial film containing nanocellulose and polyhexamethylene biguanide. Food Packaging Shelf 30:100718

Cui C, Ji N, Wang Y, Xiong L, Sun Q (2021) Bioactive and intelligent starch-based films: a review. Trends Food Sci Tech 116:854–869

Tong Z, Yang J, Lin L, Wang R, Cheng B, Chen Y, Tang L, Chen J, Ma X (2019) In situ synthesis of poly (gamma- glutamic acid)/alginate/AgNP composite microspheres with antibacterial and hemostatic properties. Carbohyd Polym 221:21–28

Bhattacharyya D, Hestekin JA, Brushaber P, Cullen L, Sikdar SK (1998) Novel poly-glutamic acid functionalized microfiltration membranes for sorption of heavy metals at high capacity. J Membrane Sci 141:121–135

Arenaza IMD, Meaurio E, Coto B, Sarasua JR (2010) Molecular dynamics modelling for the analysis and prediction of miscibility in polylactide/polyvinilphenol blends. Polymer 51:4431–4438

Rakkapao N, Vao-soongnern V (2014) Molecular simulation and experimental studies of the miscibility of chitosan/poly (ethylene oxide) blends. J Polym Res 21:606

Amini M, Mobli M, Khalili M, Ebadi-Dehaghani H (2018) Assessment of compatibility in Polypropylene/Poly (lactic acid)/Ethylene vinyl alcohol ternary blends: relating experiments and molecular dynamics simulation results. J Macromol Sci B 57:287–304

Bouzid L, Hiadsi S, Bensaid MO, Foudad FZ (2018) Molecular dynamics simulation studies of the miscibility and thermal properties of PMMA/PS polymer blend. Chinese J Phys 56:3012–3019

Wang YC, Ju SP, Chen CC, Chen HT, Hsieh JY (2014) Mechanical property prediction of starch/polymer composites by molecular dynamics simulation. RSC Adv 4:11475–11480

Liao LQ, Fu YZ, Liang XY, Mei LY, Liu YQ (2013) Diffusion of CO 2 molecules in polyethylene terephthalate/polylactide blends estimated by molecular dynamics simulations. B Korean Chem Soc 34:753–758

Meng Y, Shi X, Cai L, Zhang S, Ding K, Nie S, Luo C, Xu X, Zhang L (2018) Triple-helix conformation of a polysaccharide determined with light scattering, AFM, and molecular dynamics simulation. Macromolecules 51:10150–10159

Hoof BV, Markvoort AJ, Santen RGAV (2014) Molecular simulation of protein encapsulation in vesicle formation. J Phys Chem B 118:3346–3354

Article PubMed Google Scholar

Zhang HJ, Chi YJ, Sun B, Wang XB, Ning X (2010) Preparation of soy protein isolate-based food packaging film. Food Science 31:280–285

CAS Google Scholar

Guan R, Zhao X (2016) Preparation and characteristics of hordein/nano-TiO 2 edible film. Journal of the Chinese Cereals and Oils Association 31:66–70