Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

THEORETICAL ASPECTS ON THE MODELS OF INVENTORY MANAGEMENT UNDER UNCERTAINTY

Inventories are crude materials, work-in-procedure merchandise and totally wrapped up products that are thought to be the segment of business' benefits that are prepared or will be prepared for sale. Formulating a reasonable stock model is one of the real attentiveness toward an industry. The soonest experimental stock administration looks into go back to the second decade of the past century however the enthusiasm for this experimental range is still awesome. Again considering the unwavering quality of any procedure is a vital component in the examination exercises. Estimations of a few elements are extremely difficult to characterize or practically stunning. In such cases, fluffy models of stock administration take an vital spot. This paper breaks down conceivable parameters of existing models of stock control. An endeavor is made to give an up and coming survey of existing writing, focusing on portrayals of the attributes and sorts of stock control models that have been created.

Related Papers

ALEX GALVEZ

Bulletin of the Belgian Mathematical Society, Simon Stevin

Edward Omey

In inventory models the major objective consists of minimizing the total inventory cost and to balance the economics of large orders or large production runs against the cost of holding inventory and the cost of going short. In the present paper we analyse the uctuations in the stock and starting from some basic assumptions we obtain bounds between which the stock varies. The main purpose and use of our results is that we are able to determine the exact upper and lower stockbounds. In the paper we formulate a deterministic and a stochastic version of our model.

American Journal of Applied Mathematics and Statistics

Dr. Chukwudi Justin Ogbonna

Abhijit Bendre

isara solutions

International Research Journal Commerce arts science

The literature on the inventory modelling is increasing quickly. The aim of this article to present a renewed information about the developed inventory models under different situations. In this paper recent contribution in the field of inventory modelling for supply chain ,integrated models , defective and non-defective items are projected.

Journal of emerging technologies and innovative research

puneet shukla

In supply chain management inventory control is a challenging problem. To fulfill customer demand , companies require to have sufficient inventories in stock meanwhile these inventories have holding costs and this is frozen fund that can be lost and burdens the company’s account. Therefore, the task of inventory management is to find the quantity of inventories that will fulfill the demand, avoiding overstocks. In the present paper , an attempt is made to provide an up-to-date and complete review of existing literature, concentrating on descriptions of the characteristics and types of inventory control models that have been developed by Indian as well as Foreign authors. KEY WORDS-Inventory Management, Survival, Working Capital, Liquidity and Profitability, models under uncertainty, EOQ, EPQ. INTRODUCTION The word inventory refers to the goods or resources used by a firm for the purpose of production and sale. Inventories include the matter, which are used as helpful materials to ea...

IJSRD - International Journal for Scientific Research and Development

The quantity of goods and materials on hand is termed as inventory. Optimization of inventory is a difficult task because excess inventory results in high cost and lower inventory results in stock outs. Inventory cost is reduced by forecasting the desired inventory with continuously varying demand. If the transportation cost is less than inventory cost, the inventory level can be separated with respect to production time. When transportation cost exceeds the inventory cost, the products can be purchased in large scale. So in order to reduce the rate of uncertainty a model is developed for managing the level of inventory. This model minimizes the inventory level as the raw materials are purchased at the production start time by knowing the availability of the production sources and it avoids production stoppages.

Kaan Katircioglu

Anthony White

This paper describes a control systems approach to the management of inventory. Normal inventory operation is an example of proportional control. Several control algorithms including Pseudo-Derivative Feedback (PDF), Proportional, Integral and Derivative (PID) and Feedforward control are used in this paper to produce a more sophisticated form of inventory operation that can easily reduce stock levels by up to 80% compared to 20-30% with MRP and hence reduce cost. Settling times are reduced by a factor of 50%. Modelling was achieved using the Simulink simulation package using equations developed by Ferris and Towill for a single level industrial system model rather than a conventional System Dynamics computer package. The best controller is shown to be a PID controller with Feedforward. This controller did not cause any significant oscillatory inventory level changes. These techniques compare well with other investigators using control strategies. This has special significance for JI...

RELATED PAPERS

Juliana Anhaia

African Journal of …

International Journal on …

Pushpinder Singh

Nova Tellus

rodrigo him fábrega

Pusat Sandal Wanita Selop

RAÚL GARCÉS

Jean Piere Augusto Saavedra Villalta

The European Zoological Journal

MATEC Web of Conferences

Laurent Cordier

Philippe Hornus

The Clinical Neuropsychologist

Pia Zeinoun

Emrihan AYDIN

Annals of Computer Science and Information Systems

Ghada Moualla

Ivone Carroza

Lauryna Dabasinskaite , Lina Jankauskaite

Sustainability

Sara Grobbelaar

Journal of Protein Chemistry

Ricardo Serrano

Francisco José M. Brito

Bulletin of University of Agricultural Sciences and Veterinary Medicine Cluj-Napoca: Horticulture

Iulia Coroian

Journal of the Brazilian Computer Society

Franklin Flores

Stroke; a journal of cerebral circulation

Jong-Won Chung

Archivos de medicina

Ivan Leonardo Duque Vera

Intelligent Robots and Computer Vision XXIV: Algorithms, Techniques, and Active Vision

Paul Benjamin

International Journal of Geriatric Psychiatry

Neil Chadborn

Zenodo (CERN European Organization for Nuclear Research)

Mohitabon Komilova

See More Documents Like This

RELATED TOPICS

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

Deterministic and Stochastic İnventory Models in Production Systems: a Review of the Literature

- Review Article

- Published: 09 December 2022

- Volume 7 , pages 29–50, ( 2023 )

Cite this article

- Germán Herrera Vidal ORCID: orcid.org/0000-0002-0152-6712 1

913 Accesses

6 Citations

Explore all metrics

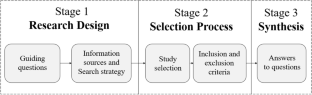

Inventory modeling allows understanding and knowing the behavior of production systems, based on the construction, solution and analysis of a representation of the real world, which allows an adequate management of the operations of any type of company or chain network. the objective of this research is focused on a literature review of deterministic and stochastic inventory models in production systems. A methodology based on three (3) stages is proposed: (i) design of the search, which includes guiding questions, sources of information and search strategies; (ii) selection process, which considers the selected studies and the inclusion and exclusion criteria; and (iii) synthesis, where the established questions are analyzed and answered. The findings show that there is scientific interest in different types of inventory models in an independent and hybrid way, more specifically in deterministic service systems with Economic Production Quantity (EPQ), Queue Model (QM) and Optimization–Linear Programming (OP) models and in stochastic supply chain management with Optimization OPT and SImulation (SIM) models. A more detailed study showed an inclination towards article-type products, with low frequency of literature review type, which makes the development of the present work attractive and interesting. The research suggests future avenues based on common characteristics, problems addressed and frequent variables, solution techniques and additional perspectives or recommendations from recent and relevant authors in the literature are framed to support decision making.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

EOQ and EPQ Production-Inventory Models with Variable Holding Cost: State-of-the-Art Review

Hesham K. Alfares & Ahmed M. Ghaithan

Multi-location Inventory Models for Retail Supply Chain Management

Inventory Models for Imperfect Quality Items: A Two-Decade Review

Data availability.

The data supporting the findings of this research paper are available and may be requested from the corresponding author.

Abboud NE (2001) A discrete-time Markov production-inventory model with machine breakdowns. Comput Ind Eng 39(1–2):95–107. https://doi.org/10.1016/S0360-8352(00)00070-X

Article Google Scholar

Ackoff RL, Sasieni M, Jiménez Ruiz E (1971) Fundamentals of operations research (No. 658.4034 A2F8). Limusa Editorial, México D.F

Aggoun L, Benkherouf L, Tadj L (1997) A hidden Markov model for an inventory system with perishable items. J Appl Math Stoch Anal 10(4):423–430

Article MathSciNet MATH Google Scholar

Agrawal N, Smith SA (2019) Optimal inventory management using retail prepacks. Eur J Oper Res 274(2):531–544. https://doi.org/10.1016/j.ejor.2018.10.014

Albrecher H, Boxma O, Essifi R, Kuijstermans R (2017) A queueing model with randomized depletion of inventory. Probab Eng Inf Sci 31(1):43–59. https://doi.org/10.1017/S0269964816000322

Ali SS, Madaan J, Chan FT, Kannan S (2013) Inventory management of perishable products: a time decay linked logistic approach. Int J Prod Res 51(13):3864–3879. https://doi.org/10.1080/00207543.2012.752587

Aliunir F, Zagloel TYM, Ardi R (2020) Discrete-Event Simulation and Optimization of Spare Parts Inventory and Preventive Maintenance Integration Model Considering Cooling Down and Machine Dismantling Time Factor. Evergreen Joint J Novel Carbon Resource Sci Green Asia Strategy 7:79–85. https://doi.org/10.5109/2740949

Al-Salamah M (2021) Economic order quantity models for the remanufacturing industry with imperfect process, two-state Markovian and two types of inventory. Int J Math Oper Res 19(1):85–103. https://doi.org/10.1504/Ijmor.2021.115429

Antic S, Djordjevic Milutinovic L, Lisec A (2022) Dynamic Discrete Inventory Control Model with Deterministic and Stochastic Demand in Pharmaceutical Distribution. Appl Sci 12(3):1536. https://doi.org/10.3390/app12031536

Aracil J (1983) Introduction to system dynamics. Madrid, Alianza

Arani M, Abdolmaleki S, Maleki M, Momenitabar M, & Liu X (2021). A simulation-optimization technique for service level analysis in conjunction with reorder point estimation and lead-time consideration: a case study in sea port. arXiv preprint arXiv:2106.00767 . https://doi.org/10.1007/978-3-030-69984-0_61

Arnold J, Köchel P (1996) Evolutionary optimization of a multi-location inventory model with lateral transshipments. In 9th International Working Seminar on Production Economics 2:401–412

Asadi A & Pinkley SN (2021). A monotone approximate dynamic programming approach for the stochastic scheduling, allocation, and inventory replenishment problem: Applications to drone and electric vehicle battery swap stations. arXiv preprint arXiv:2105.07026 . https://doi.org/10.48550/arXiv.2106.04729

Assi PN, Effanga EO (2021) Optimal manpower recruitment and promotion policies for the finitely graded systems using dynamic programming. Heliyon 7(7):e07424. https://doi.org/10.1016/j.heliyon.2021.e07424

Attar A, Raissi S, Khalili-Damghani K (2016) Simulation-optimization approach for a continuous-review, base-stock inventory model with general compound demands, random lead times, and lost sales. Simulation 92(6):547–564. https://doi.org/10.1177/0037549716644055

Axsäter S (2015) Inventory control (Vol. 225). Cham. Springer International Publishing

Azoury KS, Miyaoka J (2020) Optimal and simple approximate solutions to a production-inventory system with stochastic and deterministic demand. Eur J Oper Res 286(1):178–189. https://doi.org/10.1016/j.ejor.2020.03.009

Baek JW, Moon SK (2014) The M/M/1 queue with a production-inventory system and lost sales. Appl Math Comput 233:534–544. https://doi.org/10.1016/j.amc.2014.02.033

Baek JW, Bae YH, Lee HW, Ahn S (2018) Continuous-type (s, Q)-inventory model with an attached M/M/1 queue and lost sales. Perform Eval 125:68–79. https://doi.org/10.1016/j.peva.2018.07.003

Bahagia SN (2006) Sistem Inventori. Bandung, ITB Press

Bahl HC, Taj S (1991) A data-dependent efficient implementaton of the wagner-whitin algorithm for lot-sizing. Comput Ind Eng 20(2):289–291. https://doi.org/10.1016/0360-8352(91)90033-3

Balagopal N, Deepthi CP, Jayaprasad PN, Jacob V (2021) Comparison of discrete time inventory systems with positive service time and lead time. Korea J Math 29(2):371–386. https://doi.org/10.11568/kjm.2021.29.2.371

Baltacioğlu G, Temiz I, Serpil E (2011) Fuzzy Wagner Whitin algorithm and an application of class I supplies. Gazi Univ J Sci 24(1):125–134

Google Scholar

Benkherouf L, Mahmoud MG (1996) On an inventory model for deteriorating items with increasing time-varying demand and shortages. J Oper Res Soc 47(1):188–200. https://doi.org/10.1057/jors.1996.17

Article MATH Google Scholar

Bhowmick J & Samanta GP (2011) A deterministic inventory model of deteriorating items with two rates of production, shortages, and variable production cycle. Int Sch Res Notices. https://doi.org/10.5402/2011/657464

Blackburn JD, Millen RA (1982) The impact of a rolling schedule in a multi-level MRP system. J Oper Manag 2(2):125–135. https://doi.org/10.1016/0272-6963(82)90028-6

Blanco F (2003) Cost accounting and management analytics for decision making. Ediciones, 9th edn. Deusto Estratégicas, Madrid

Bookbinder JH, & Tan JY (1985) Two lot-sizing heuristics for the case of deterministic time-varying demands. Int J Oper Prod Manag. https://doi.org/10.1108/eb054746

Buffett S, Scott N (2004) An algorithm for procurement in supply chain management. In AAMAS 2004 Workshop on Trading Agent Design and Analysis. New York

Bukhari FA, El-Gohary A (2012) Optimal control of a production-maintenance system with deteriorating items. J King Saud Univ Sci 24(4):351–357. https://doi.org/10.1016/j.jksus.2011.08.001

Buschiazzo M, Mula J, Campuzano-Bolarin F (2020) Simulation optimization for the inventory management of healthcare supplies. Int J Simul Model 19(2):255–266. https://doi.org/10.2507/IJSIMM19-2-514

Bustos Flores CE, Chacón Parra GB (2012) Deterministic inventory models for independent demand: A study in Venezuela. Contaduría y Adm 57(3):239–258

Cárdenas-Barrón LE, Chung KJ, Treviño-Garza G (2014) Celebrating a century of the economic order quantity model in honor of Ford Whitman Harris. Int J Prod Econ 155:1–7. https://doi.org/10.1016/j.ijpe.2014.07.002

Cervera MLS (2012) Inventory management: a new formula for calculating competitiveness. Ad-QueliteEditorial, Bogotá D.C

Chakraborty T, Giri BC (2012) Joint determination of optimal safety stocks and production policy for an imperfect production system. Appl Math Model 36(2):712–722. https://doi.org/10.1016/j.apm.2011.07.012

Chakravarthy SR, Rao BM (2021) Queuing-Inventory Models with MAP Demands and Random Replenishment Opportunities. Mathematics 9(10):1092. https://doi.org/10.3390/math9101092

Chakravarthy SR, Rumyantsev A (2020) Analytical and simulation studies of queueing-inventory models with MAP demands in batches and positive phase type services. Simul Model Pract Theory 103:102092. https://doi.org/10.1016/j.simpat.2020.102092

Chan LMA & Karakul M (2008) Inventory control theory: deterministic and stochastic models. Logostics Engineering Handbook, Taylor GD, CRC press, Boca Raton 1–26

Chase R, Aquilano N (1995) Production and operations management and administration, 6th edn. McGraw-Hill, Mexico

Chase R, Jacobs R, Aquilano N (2010) Operations, Production and Supply Chain Management. Mc Graw Hill, Mexico

Cheikhrouhou N, Sarkar B, Ganguly B, Malik AI, Batista R, Lee YH (2018) Optimization of sample size and order size in an inventory model with quality inspection and return of defective items. Ann Oper Res 271(2):445–467. https://doi.org/10.1007/s10479-017-2511-6

Chen SH, Chang SM (2008) Optimization of fuzzy production inventory model with unrepairable defective products. Int J Prod Econ 113(2):887–894. https://doi.org/10.1016/j.ijpe.2007.11.004

Chen F, Song JS (2001) Optimal policies for multiechelon inventory problems with Markov-modulated demand. Oper Res 49(2):226–234. https://doi.org/10.1287/opre.49.2.226.13528

Cheng F, Sethi SP (1999a) Optimality of state-dependent (s, S) policies in inventory models with Markov-modulated demand and lost sales. Prod Oper Manag 8(2):183–192. https://doi.org/10.1111/j1937-5956.1999.tb00369.x

Cheng F, Sethi SP (1999b) A periodic review inventory model with demand influenced by promotion decisions. Manage Sci 45(11):1510–1523. https://doi.org/10.1287/mnsc.45.11.1510

Cheng TCE, Siu RWM (1989) Comparison of EOQ-independent lot-sizing heuristic rules. Int J Syst Sci 20(2):297–310. https://doi.org/10.1080/00207728908910127

Chiu H (1995) A heuristic (r, t) periodic review perishable inventory model with lead times. Int J Prod Econ 42(1):1–15. https://doi.org/10.1016/0925-5273(95)00119-0

Article MathSciNet Google Scholar

Choi HG, Malstrom EM, Classen RJ (1984) Computer simulation of lot-sizing algorithms in three-stage multi-echelon inventory systems. J Oper Manag 4(3):259–277. https://doi.org/10.1016/0272-6963(84)90015-9

Choi TM (2013) Handbook of EOQ inventory problems: stochastic and deterministic models and applications 197. Springer Science & Business Media. https://doi.org/10.1007/978-1-4614-7639-9

Chołodowicz E, Orłowski P (2021) Development of new hybrid discrete-time perishable inventory model based on Weibull distribution with time-varying demand using system dynamics approach. Comput Ind Eng 154:107151. https://doi.org/10.1016/j.cie.2021.107151

Chou M, Sim CK, Yuan XM (2013) Optimal policies for inventory systems with two types of product sharing common hardware platforms: Single period and finite horizon. Eur J Oper Res 224(2):283–292. https://doi.org/10.1016/j.ejor.2012.07.038

Chowdhury NT, Baki MF, Azab A (2018) Dynamic economic lot-sizing problem: A new O (T) algorithm for the Wagner-Whitin model. Comput Ind Eng 117:6–18. https://doi.org/10.1016/j.cie.2018.01.010

Chung CJ, Wee HM (2011) Short life-cycle deteriorating product remanufacturing in a green supply chain inventory control system. Int J Prod Econ 129(1):195–203. https://doi.org/10.1016/j.ijpe.2010.09.033

Chung CJ, Widyadana GA, Ming Wee H (2011) Economic production quantity model for deteriorating inventory with random machine unavailability and shortage. Int J Prod Res 49(3):883–902. https://doi.org/10.1080/00207540903460232

Chung KJ, Cárdenas-Barrón LE, Ting PS (2014) An inventory model with non-instantaneous receipt and exponentially deteriorating items for an integrated three layer supply chain system under two levels of trade credit. Int J Prod Econ 155:310–317. https://doi.org/10.1016/j.ijpe.2013.12.033

Churchman CW, Ackoff RL, Arnoff EL (1957) Introduction to operations research. Oxford, England: Wiley. https://doi.org/10.2307/3006881

Clark AJ (1960) The use of simulation to evaluate a multiechelon, dynamic inventory model. Naval Res Logist Q 7(4):429–445. https://doi.org/10.1002/nav.3800070416

Cruz Moreno FDM, Vargas Ortiz MR (2017) Dynamic programming techniques and their implementation in spreadsheets (Doctoral dissertation). Leon, Nicaragua

Das BC, Das B, Mondal SK (2013) Integrated supply chain model for a deteriorating item with procurement cost dependent credit period. Comput Ind Eng 64(3):788–796. https://doi.org/10.1016/j.cie.2012.12.020

Dawande M, Gavirneni S, Tayur S (2006) Effective heuristics for multiproduct partial shipment models. Oper Res 54(2):337–352. https://doi.org/10.1287/opre.1050.0263

De Kumar S, Kundu PK, Goswami A (2003) An economic production quantity inventory model involving fuzzy demand rate and fuzzy deterioration rate. J Appl Math Comput 12(1):251–260. https://doi.org/10.1007/BF02936197

Diaz R, Bailey MP, Kumar S (2016) Analyzing a lost-sale stochastic inventory model with Markov-modulated demands: A simulation-based optimization study. J Manuf Syst 38:1–12. https://doi.org/10.1016/j.jmsy.2015.09.007

Đorđević L, Antić S, Čangalović M, Lisec A (2017) A metaheuristic approach to solving a multiproduct EOQ-based inventory problem with storage space constraints. Optim Lett 11(6):1137–1154. https://doi.org/10.1007/s11590-016-1009-5

Duc NTTT, Tai PD & Buddhakulsomsiri J (2020). Approximating Measures of Performance of a Periodic Review Inventory System by Using Markov Chain. In 2020 IEEE 7th International Conference on Industrial Engineering and Applications (ICIEA) pp. 543–547. IEEE. https://doi.org/10.1109/ICIEA49774.2020.9102069

Dye CY (2013) The effect of preservation technology investment on a non-instantaneous deteriorating inventory model. Omega 41(5):872–880. https://doi.org/10.1016/j.omega.2012.11.002

Dye CY, Hsieh TP (2012) An optimal replenishment policy for deteriorating items with effective investment in preservation technology. Eur J Oper Res 218(1):106–112. https://doi.org/10.1016/j.ejor.2011.10.016

Eppen GD, Gould FJ, Schmidt CP (2000) Operations research in the management sciences. Pearson Educación Editorial. Mexico D.F

Escobar JW, Linfati R, Jaimes WA (2017) Inventory management for distributors of perishable products. Eng Dev 35(1):219–239

Esmaeili M, Nasrabadi M (2021) An inventory model for single-vendor multi-retailer supply chain under inflationary conditions and trade credit. J Ind Prod Eng 38(2):75–88. https://doi.org/10.1080/21681015.2020.1845248

Fabens AJ (1961) The solution of queueing and inventory models by semi-Markov processes. J R Stat Soc: Ser B (methodol) 23(1):113–127. https://doi.org/10.1111/j.2517-6161.1961.tb00395.x

Fathi M, Khakifirooz M, Diabat A, Chen H (2021) An integrated queuing-stochastic optimization hybrid Genetic Algorithm for a location-inventory supply chain network. Int J Prod Econ 237:108139. https://doi.org/10.1016/j.ijpe.2021.108139

Fattah J, Ezzine L, Moussami HE, Lachhab A (2016) Analysis of the performance of inventory management systems using the SCOR model and Batch Deterministic and Stochastic Petri Nets. Int J Eng Bus Manag 8:1847979016678370. https://doi.org/10.1177/1847979016678370

Fawcett SE, Waller MA, & Fawcett AM (2010) Elaborating a dynamic systems theory to understand collaborative inventory successes and failures. Int J Logist Manag. https://doi.org/10.1108/09574091011089835

Ferguson M, Jayaraman V, Souza GC (2007) Note: An application of the EOQ model with nonlinear holding cost to inventory management of perishables. Eur J Oper Res 180(1):485–490. https://doi.org/10.1016/j.ejor.2006.04.031

Firoozi Z, Tang SH, Ariafar S, Ariffin MKAM (2013) An optimization approach for a joint location inventory model considering quantity discount policy. Arab J Sci Eng 38(4):983–991. https://doi.org/10.1007/s13369-012-0360-9

Fliedner M, Boysen N, Scholl A (2011) On the part inventory model sequencing problem: Complexity and beam search heuristic. J Sched 14(1):17–25. https://doi.org/10.1007/s10951-010-0214-9

Forrester JW (1970) Urban dynamics. IMR Ind Manag Rev (pre-1986) 11(3):67

Gaither N, Frazier G (2000) Production and operations management, 4th edn. International Thomson Editores, Mexico

Gani AN & Rafi UM (2020) A new method to discussing the manufacturing defects in EOP/EPQ inventory models with shortages using fuzzy techniques. Adv Appl Math Sci 19(11):1189–1203

Gayon JP, Benjaafar S, & Véricourt FD (2009) Using imperfect advance demand information in production-inventory systems with multiple customer classes. Manuf Serv Oper Manag 128-143. https://doi.org/10.1287/msom.1070.0201

Gharaei A Pasandideh SHR & Khamseh AA (2017). Inventory model in a four-echelon integrated supply chain: Modeling and optimization. Journal of Modelling in Management. https://doi.org/10.1108/JM2-07-2016-0065

Ghasemi P, Khalili-Damghani K (2021) A robust simulation-optimization approach for pre-disaster multi-period location-allocation-inventory planning. Math Comput Simul 179:69–95. https://doi.org/10.1016/j.matcom.2020.07.022

Gou Q, Liang L, Huang Z, Xu C (2008) A joint inventory model for an open-loop reverse supply chain. Int J Prod Econ 116(1):28–42. https://doi.org/10.1016/j.ijpe.2008.07.009

Goyal SK, Cardenas-Barron LE (2002) Note on: Economic production quantity model for items with imperfect quality - a practical approach. Int J Prod Econ 77:85–87. https://doi.org/10.1016/S0925-5273(01)00203-1

Goyal SK, Giri BC (2003) The production–inventory problem of a product with time varying demand, production and deterioration rates. Eur J Oper Res 147(3):549–557. https://doi.org/10.1016/S0377-2217(02)00296-5

Goyal SK, Satir AT (1989) Joint replenishment inventory control: deterministic and stochastic models. Eur J Oper Res 38(1):2–13. https://doi.org/10.1016/0377-2217(89)90463-3

Gupta SM, Brennan L (1992) Lot sizing and backordering in multi-level product structures. Prod Invent Manag J 33(1):27 ( https://www.proquest.com/docview/199876091 )

Haddock J, Bengu G (1987) Application of a simulation optimization system for a continuous review inventory model. In Proceedings of the 19th conference on Winter simulation, pp. 382–390

Hadley G, Whitin T (1963) Analysis of inventory systems, 1st edn. Prentice Hall Inc, New Jersey

MATH Google Scholar

Haneveld WKK (1980) A dual of a dynamic inventory control model: the deterministic and stochastic case. Recent Results in Stochastic Programming. Springer, Berlin, pp 67–98. https://doi.org/10.1007/978-3-642-51572-9_6

Chapter Google Scholar

Hanukov G, Avinadav T, Chernonog T, Yechiali U (2021) A multi-server system with inventory of preliminary services and stock-dependent demand. Int J Prod Res 59(14):4384–4402. https://doi.org/10.1080/00207543.2020.1762945

Hariga M, Ben-Daya M (1999) Some stochastic inventory models with deterministic variable lead time. Eur J Oper Res 113(1):42–51. https://doi.org/10.1016/S0377-2217(97)00441-4

Harris FW (1913) How Many Parts to Make At Once. Fact Mag Manag 10(2):135–136. https://doi.org/10.1287/opre.38.6.947

Hasan MR, Mashud AHM, Daryanto Y, & Wee HM (2020). A non-instantaneous inventory model of agricultural products considering deteriorating impacts and pricing policies. Kybernetes. https://doi.org/10.1108/K-05-2020-0288

He Z, Jiang W (2018) A new belief Markov chain model and its application in inventory prediction. Int J Prod Res 56(8):2800–2817. https://doi.org/10.1080/00207543.2017.1405166

He Y, Wang S (2012) Analysis of production-inventory system for deteriorating items with demand disruption. Int J Prod Res 50(16):4580–4592. https://doi.org/10.1080/00207543.2011.615351

Heizer J, Render B (2006) Production Management Tactical Decisions. Prentice Hall, Spain

Ho TF, Lin CC, Lin CL (2020) Using fuzzy sets and Markov chain method to carry out inventory strategies with different recovery levels. Symmetry 12(8):1226. https://doi.org/10.3390/sym12081226

Hsu PH, Wee HM, Teng HM (2010) Preservation technology investment for deteriorating inventory. Int J Prod Econ 124(2):388–394. https://doi.org/10.1016/j.ijpe.2009.11.034

Huang D, Zhao QH, Fan CC (2010) Simulation-based optimization of inventory model with products substitution. Innovative quick response programs in logistics and supply chain management. Springer, Berlin, pp 297–312. https://doi.org/10.1007/978-3-642-04313-0_15

Huang YF, Weng MW, Su RH, Lai KK (2017) An EPQ model for deteriorating items with allowable shortage and price difference-dependent demand. In 2017 IEEE 8th International Conference on Awareness Science and Technology (iCAST), pp. 75–81. IEEE. https://doi.org/10.1109/ICAwST.2017.8256527

Inderfurth K, Kiesmüller GP (2015) Exact and heuristic linear-inflation policies for an inventory model with random yield and arbitrary lead times. Eur J Oper Res 245(1):109–120. https://doi.org/10.1016/j.ejor.2015.03.006

Jackson I, Tolujevs J, Kegenbekov Z (2020) Review of Inventory Control Models: A Classification Based on Methods of Obtaining Optimal Control Parameters. Transport Telecommun 21(3):191–202. https://doi.org/10.2478/ttj-2020-0015

Jamshidi H (2009) Lean manufacturing and formation of production cycles with the Wagner-Whitin algorithm. J Glob Bus Issues 3(1)

Jamshidi H, Brown RA (1993) Development of production cycles for group technology environment with the Wagner-Whitin algorithm. Comput Ind Eng 24(2):199–207. https://doi.org/10.1016/0360-8352(93)90008-L

Jana DK, Das B (2017) A two-storage multi-item inventory model with hybrid number and nested price discount via hybrid heuristic algorithm. Ann Oper Res 248(1–2):281–304. https://doi.org/10.1007/s10479-016-2162-z

Jana DK, Maity K, Das B, Roy TK (2013) A fuzzy simulation via contractive mapping genetic algorithm approach to an imprecise production inventory inventory model under volume flexibility. J Simul 7(2):90–100. https://doi.org/10.1057/jos.2012.23

Jeenanunta C, Kongtarat V, Buddhakulsomsiri J (2021) A simulation-optimisation approach to determine optimal order-up-to level for inventory system with long lead time. Int J Logist Syst Manag 38(2):253–276. https://doi.org/10.1504/IJLSM.2021.113250

Jeyanthi N, Radhakrishnan P (2010) Optimizing multi product inventory using genetic algorithm for efficient supply chain management involving lead time. Int J Comp Sci Netw Sec 10(5):231–239

Jing F, Chao X (2021) A dynamic lot size model with perishable inventory and stockout. Omega 103:102421. https://doi.org/10.1016/j.omega.2021.102421

Johansen SG (2021) The Markov model for base-stock control of an inventory system with Poisson demand, non-crossing lead times and lost sales. Int J Prod Econ 231:107913. https://doi.org/10.1016/j.ijpe.2020.107913

Jun-Jun G & Ting K (2009) A joint decision model of inventory control and promotion optimization based on demand forecasting. In 2009 IEEE International Conference on Automation and Logistics, pp. 119–123. IEEE. https://doi.org/10.1109/ICAL.2009.5262965

Kamath KR, Pakkala TPM (2002) A Bayesian approach to a dynamic inventory model under an unknown demand distribution. Comput Oper Res 29(4):403–422. https://doi.org/10.1016/S0305-0548(00)00075-7

Karampour MM, Hajiaghaei-Keshteli M, Fathollahi-Fard AM, & Tian G (2020) Metaheuristics for a bi-objective green vendor managed inventory problem in a two-echelon supply chain network. Sci Iran. https://doi.org/10.24200/SCI.2020.53420.3228

Kian R, Berk E, Gürler Ü, Rezazadeh H, Yazdani B (2021) The effect of economies-of-scale on the performance of lot-sizing heuristics in rolling horizon basis. Int J Prod Res 59(8):2294–2308. https://doi.org/10.1080/00207543.2020.1730464

Kishore RA, Tiwari R, Kumar P, Gupta A, Sharma AK (2011) N-Period dynamic deterministic inventory model for perishable goods. IUP J Oper Manag 10(1)

Kumar P (2021) Optimal policies for inventory model with shortages, time-varying holding and ordering costs in trapezoidal fuzzy environment. Independ J Manag Prod 12(2):557–574. https://doi.org/10.14807/ijmp.v12i2.1212

Kumar R, Soodan BS, Sharma S (2021) Modelling Health Care Queue Management System Facing Patients Impatience using Queuing Theory. Reliab Theory Appl 16(1):61

Labadi K, Chen H, Amodeo L, Chu C (2005) Batch deterministic and stochastic petri nets: Modelling, analysis and application to inventory systems. IFAC Proc 38(1):343–348. https://doi.org/10.3182/20050703-6-CZ-1902.00341

Labadi K, Chen H, Amodeo L (2007) Modeling and performance evaluation of inventory systems using batch deterministic and stochastic Petri nets. IEEE Trans Syst Man Cybern Part C Appl Rev 37(6):1287–1302. https://doi.org/10.1109/TSMCC.2007.905860

Landeta JMI, Manuel J (2012) Operations research. Editorial Trillas, México D.F. https://www.academia.edu/28130294

Larsen C, Turkensteen M (2014) A vendor managed inventory model using continuous approximations for route length estimates and Markov chain modeling for cost estimates. Int J Prod Econ 157:120–132. https://doi.org/10.1016/j.ijpe.2014.08.001

Lee CF, Chung CP (2012) An inventory model for deteriorating items in a supply chain with system dynamics analysis. Procedia Soc Behav Sci 40:41–51. https://doi.org/10.1016/j.sbspro.2012.03.159

Lee S, Kim D (2014) An optimal policy for a single-vendor single-buyer integrated production-distribution model with both deteriorating and defective items. Int J Prod Econ 147:161–170. https://doi.org/10.1016/j.ijpe.2013.09.011

Li L, Wan J (2008) Simulation for constrained optimization of inventory system by using arena and OptQuest. In 2008 International Conference on Computer Science and Software Engineering 2:202–205. IEEE. https://doi.org/10.1109/CSSE.2008.1217

Liao JJ (2007) On an EPQ model for deteriorating items under permissible delay in payments. Appl Math Model 31(3):393–403. https://doi.org/10.1016/j.apm.2005.11.016

Liu L, Liu X, Yao DD (2004) Analysis and optimization of a multistage inventory-queue system. Manage Sci 50(3):365–380. https://doi.org/10.1287/mnsc.1030.0196

Liu M, Feng M, Wong CY (2014) Flexible service policies for a Markov inventory system with two demand classes. Int J Prod Econ 151:180–185. https://doi.org/10.1016/j.ijpe.2013.10.010

Mahata GC (2011) A Production Lot-Size Model for Perishable Items Under Two Level Trade Credit Policy for a Retailer with a Powerful Position in a Supply Chain System. J Math Model Algorithms 10(4):323–340. https://doi.org/10.1007/s10852-011-9158-0

Mahata GC (2012) An EPQ-based inventory model for exponentially deteriorating items under retailer partial trade credit policy in supply chain. Expert Syst Appl 39(3):3537–3550. https://doi.org/10.1016/j.eswa.2011.09.044

Mahata GC, Goswami A (2007) An EOQ model for deteriorating items under trade credit financing in the fuzzy sense. Prod Plann Control 18(8):681–692. https://doi.org/10.1080/09537280701619117

Maiti AK (2020) Multi-item fuzzy inventory model for deteriorating items in multi-outlet under single management. J Manag Anal 7(1):44–68. https://doi.org/10.1080/23270012.2019.1699873

Maity K, Maiti M (2009) Optimal inventory policies for deteriorating complementary and substitute items. Int J Syst Sci 40(3):267–276. https://doi.org/10.1080/00207720802303218

Mareeswaran M, & Anandhi M (2021) Optimization of inventory in agriculture material processing industry by using multi-item deterministic model. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.02.747

Mathur K, Solow D, Reyes D, Marina ATT, Tec JR (1996) Operations research: the art of decision making. Prentice Hall Hispanoamericana-Pearson Educacion Editorial, Mexico D.F

Maulana SKDB (2021) Inventory control analysis of fabric raw materials A50–00766 using economic order quantity model. PT Formosa Bag Indonesia-Management Trainee Program

Meissner J, Senicheva OV (2018) Approximate dynamic programming for lateral transshipment problems in multi-location inventory systems. Eur J Oper Res 265(1):49–64. https://doi.org/10.1016/j.ejor.2017.06.049

Melikov AZ & Shahmaliyev MO (2019). Queueing System M/M/1/∞ with Perishable Inventory and Repeated Customers. Autom Remote Control 80(1). https://doi.org/10.1134/S0005117919010053

Mishra U, Mashud AHM, Tseng ML, Wu JZ (2021) Optimizing a Sustainable Supply Chain Inventory Model for Controllable Deterioration and Emission Rates in a Greenhouse Farm. Mathematics 9(5):495. https://doi.org/10.3390/math9050495

Mokhtari H, Hasani A, Fallahi A (2021) Multi-product constrained economic production quantity models for imperfect quality items with rework. International Journal of Industrial Engineering & Production Research 32(2):0–0. http://ijiepr.iust.ac.ir/article-1-950

Mousavi SM, Sadeghi J, Niaki STA, Alikar N, Bahraininejad A, Metselaar HSSSC (2014) Two parameter-tuned meta-heuristics for a discounted inventory control problem in a fuzzy environment. Inf Sci 276:42–62. https://doi.org/10.1016/j.ins.2014.02.046

Murdapa PS (2021) Modeling the Multi-channel Section in the Supply Chain System using the Multiserver Queue Analogy. J Teknik Ind 23(1):47–54. https://doi.org/10.9744/jti.23.1.47-54

Nadyatama D, Aini Q, Utami MC (2016) Analysis of commodity inventory with exponential smoothing and silver meal algorithm (Case study). In 2016 4th International Conference on Cyber and IT Service Management, pp. 1–6. IEEE. https://doi.org/10.1109/CITSM.2016.7577527

Nahmias S (2007) Production and operations analysis, 5th edn. McGraw-Hill Interamericana, Mexico

Nair AN, Jacob MJ, Krishnamoorthy A (2015) The multi server M/M/(s, S) queueing inventory system. Ann Oper Res 233(1):321–333. https://doi.org/10.1007/s10479-013-1405-5

Najafnejhad E, Roodsari MT, Sepahrom S, Jenabzadeh M (2021) A mathematical inventory model for a single-vendor multi-retailer supply chain based on the Vendor Management Inventory Policy. Int J Syst Assur Eng Manag 12(3):579–586. https://doi.org/10.1007/s13198-021-01120-z

Nasr WWW, Salameh MK, Moussawi-Haidar L (2014) Integrating the economic production model with deteriorating raw material over multi-production cycles. Int J Prod Res 52(8):2477–2489. https://doi.org/10.1080/00207543.2013.877614

Naylor TH, Balıntey JL, Burdıck DS (1982) Computer simulation techniques (No. QA 76, 5. N36 1973.). John Wiley

Nobil AH, Sedigh AHA, Cárdenas-Barrón LE (2020) A multiproduct single machine economic production quantity (EPQ) inventory model with discrete delivery order, joint production policy and budget constraints. Ann Oper Res 286(1):265–301. https://doi.org/10.1007/s10479-017-2650-9

Noori H, Radford R (1997) Operations and production management. Total quality and rapid responsive response. McGraw-Hill Interamericana, Colombia

Nunes P (2015) knoow.net. Retrieved from Wagner-Whitin Algorithm: http://knoow.net/es/cieeconcom/gestion/algoritmo-de-wagner-whitin/

Odedairo BO, Alaba EH, Edem I (2020) A System Dynamics Model to Determine the Value of Inventory Holding Cost. J Eng Stud Res 26(3):112–123. https://doi.org/10.29081/jesr.v26i3.213

Ogata K, Sanchez GLP (1987) System dynamics. Prentice-Hall, Hispanoamericana, pp 494–523

Omar M & Deris MM (2001) The Silver-Meal Heuristic Method For Deterministic Time-Varying Demand. Matematika: Malaysia J Ind Appl Math 7–14. https://doi.org/10.11113/matematika.v17.n.100

Otten S, Krenzler R, Daduna H (2016) Models for integrated production-inventory systems: steady state and cost analysis. Int J Prod Res 54(20):6174–6191. https://doi.org/10.1080/00207543.2015.1082669

Pan S, Nigrelli M, Ballot E, Sarraj R, Yang Y (2015) Perspectives of inventory control models in the Physical Internet: A simulation study. Comput Ind Eng 84:122–132. https://doi.org/10.1016/j.cie.2014.11.027

Parra Guerrero F (2020) Inventory management. Esic Editorial, Madrid

Pasandideh SHR, Niaki STA, Mousavi SM (2013) Two metaheuristics to solve a multi-item multiperiod inventory control problem under storage constraint and discounts. Int J Adv Manuf Technol 69(5–8):1671–1684. https://doi.org/10.1007/s00170-013-5130-7

Pegels CC, Jelmert AE (1970) An evaluation of blood-inventory policies: A Markov chain application. Oper Res 18(6):1087–1098. https://doi.org/10.1287/opre.18.6.1087

Pérez F, Torres F (2014) Inventory models with perishable products: literature review. In: Enginería 19 (2):9–40. http://www.scielo.org.co/scielo.php?pid=S0121-750X201400020000

Ponsot E (2008) The study of inventories in the supply chain: a look from the underdevelopment. Actualidad Contable Faces 11(17):82–94. Venezuela. https://www.redalyc.org/pdf/257/25711784008.pdf

Poormoaied S (2021). Inventory decision in a periodic review inventory model with two complementary products. Ann Oper Res 1–34

Raafat F (1991) Survey of literature on continuously deteriorating inventory models. J Oper Res Soc 42(1):27–37. https://doi.org/10.1057/jors.1991.4

Rabta B (2020) An Economic Order Quantity inventory model for a product with a circular economy indicator. Comput Ind Eng 140:106215. https://doi.org/10.1016/j.cie.2019.106215

Rahman MS, Manna AK, Shaikh AA, Bhunia AK (2020) An application of interval differential equation on a production inventory model with interval-valued demand via center-radius optimization technique and particle swarm optimization. Int J Intell Syst 35(8):1280–1326. https://doi.org/10.1002/int.22254

Rani M (2020) An integrated EPQ inventory model for delayed deteriorating items with time and price dependent demand with inflation under discount policy. Int J Innov Sci Res Technol 5(5):1115–1119

Rau H, Wu MY, Wee HM (2003) Integrated inventory model for deteriorating items under a multi-echelon supply chain environment. Int J Prod Econ 86(2):155–168. https://doi.org/10.1016/S0925-5273(03)00048-3

Rau H, Wu MY, Wee HM (2004) Deteriorating item inventory model with shortage due to supplier in an integrated supply chain. Int J Syst Sci 35(5):293–303. https://doi.org/10.1080/00207720410001714833

Riezebos J, Gaalman GJC (2009) A single-item inventory model for expected inventory order crossovers. Int J Prod Econ 121(2):601–609. https://doi.org/10.1016/j.ijpe.2006.10.004

Ríos F, Martínez A, Palomo T, Cáceres S, Díaz M (2008) Probabilistic inventories with continuous revision independent demand, models with new orders. Sci Ergo-Sum Multidiscip Sci J Foresight 15(3):251–258

Rosenkranz F (1973) Deterministic solution and stochastic simulation of a simple production-inventory model. Z Oper Res 17(4):141–152. https://doi.org/10.1007/BF01956730

Roy A, Samanta GP (2011) Inventory model with two rates of production for deteriorating items with permissible delay in payments. Int J Syst Sci 42(8):1375–1386

Ruidas S, Seikh MR, Nayak PK (2019) An EPQ model with stock and selling price dependent demand and variable production rate in interval environment. International J Syst Assura Eng Manag 1–15. https://doi.org/10.1007/s13198-019-00867-w

Ruiz Vallejo L, Suarez Méndez J, Caicedo EM, Heredia Peña J (2015) Application of Monte Carlo simulation in an inventory system. http://hdl.handle.net/10823/960

Sadeghi J, Mousavi SM, Niaki STA, Sadeghi S (2014) Optimizing a bi-objective inventory model of a three-echelon supply chain using a tuned hybrid bat algorithm. Transport Res Part E: Logist Transport Rev 70:274–292. https://doi.org/10.1016/j.tre.2014.07.007

Sadeghi J, Mousavi SM, Niaki STA (2016) Optimizing an inventory model with fuzzy demand, backordering, and discount using a hybrid imperialist competitive algorithm. Appl Math Model 40(15–16):7318–7335. https://doi.org/10.1016/j.apm.2016.03.013

Saffari M, Asmussen S, Haji R (2013) The M/M/1 queue with inventory, lost sale, and general lead times. Que Syst 75(1):65–77. https://doi.org/10.1007/s11134-012-9337-3

Salameh M, Jaber MY (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64:59–64. https://doi.org/10.1016/S0925-5273(99)00044-4

Sarkar B (2013) A production-inventory model with probabilistic deterioration in two-echelon supply chain management. Appl Math Model 37(5):3138–3151. https://doi.org/10.1016/j.apm.2012.07.026

Sasser WE, Burdick DS, Graham DA, Naylor TH (1970) The application of sequential sampling to simulation: an example inventory model. Commun ACM 13(5):287–296. https://doi.org/10.1145/362349.362357

Saydam C, Evans JR (1990) A comparative performance analysis of the Wagner-Whitin algorithm and lot-sizing heuristics. Comput Ind Eng 18(1):91–93. https://doi.org/10.1016/0360-8352(90)90044-M

Saydam C, Mcknew M (1987) A Fast Microcomputer Program For Ordering Using The Wagner. Prod Invent Manag J 28(4):15

Schulz T (2009) A new silver-meal based heuristic for the single-item dynamic lot sizing problem with returns and remanufacturing. Working Paper Series. Magdeburg, Germany. https://doi.org/10.24352/UB.OVGU-2018-417

Schulz T (2011) A new Silver-Meal based heuristic for the single-item dynamic lot sizing problem with returns and remanufacturing. Int J Prod Res 49(9):2519–2533. https://doi.org/10.1080/00207543.2010.532916

Schwarz M, Sauer C, Daduna H, Kulik R, Szekli R (2006) M/M/1 queueing systems with inventory. Que Syst 54(1):55–78. https://doi.org/10.1007/s11134-006-8710-5

Sekar T, Uthayakumar R (2018) A production inventory model for single vendor single buyer integrated demand with multiple production setups and rework. Uncertain Supply Chain Manag 6(1):75–90. https://doi.org/10.5267/j.uscm.2017.6.001

Shen Z, Dessouky M, Ordonez F (2016) Perishable Inventory Management System with a Minimum Volume Constraint. Operational Research for Emergency Planning in Healthcare, 1st edn. Palgrave Macmillan, London, pp 288–329. https://doi.org/10.1057/9781137535696_12

Shokouhifar M, Sabbaghi MM & Pilevari N (2021). Inventory management in blood supply chain considering fuzzy supply/demand uncertainties and lateral transshipment. Transfus Apher Sci 103103. https://doi.org/10.1016/j.transci.2021.103103

Silver EA (2004) An overview of heuristic solution methods. J Oper Res Soc 55(9):936–956. https://doi.org/10.1057/palgrave.jors.2601758

Simpson NC (2001) Questioning the relative virtues of dynamic lot sizing rules. Comput Oper Res 28(9):899–914. https://doi.org/10.1016/S0305-0548(00)00015-0

Sinaga MS, Purba O, Nasution H (2020) Finite markov chain in inventory control. In Journal of Physics: Conference Series 1462(1):012039. IOP Publishing

Singh S, Singh SR, Sharma S (2017) A partially backlogged EPQ model with demand dependent production and non-instantaneous deterioration. Int J Math Oper Res 10(2):211–228. https://doi.org/10.1504/IJMOR.2017.081926

Sipper D, Bulin R (1998) Production planning and control. McGraw-Hill Interamericana, Mexico

Song JS (1998) On the order fill rate in a multi-item, base-stock inventory system. Oper Res 46(6):831–845. https://doi.org/10.1287/opre.46.6.831

Sridhar P, Vishnu CR, & Sridharan R (2021). Simulation of inventory management systems in retail stores: a case study. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2021.05.314

Srivastav A, Agrawal S (2016) Multi-objective optimization of hybrid backorder inventory model. Expert Syst Appl 51:76–84. https://doi.org/10.1016/j.eswa.2015.12.032

Ståhl G (1994) Optimal stand level forest inventory intensities under deterministic and stochastic stumpage value assumptions. Scand J for Res 9(1–4):405–412. https://doi.org/10.1080/02827589409382858

Taft EW (1918) The most economical production lot. Iron Age 101:1410–1412

Taleizadeh AA, Niaki STA, Nikousokhan R (2011) Constraint multiproduct joint-replenishment inventory control problem using uncertain programming. Appl Soft Comput 11(8):5143–5154. https://doi.org/10.1016/j.asoc.2011.05.045

Taleizadeh AA, Cárdenas-Barrón LE (2013) Hybrid metaheuristics algorithms for inventory management problems. In Meta-Heuristics Optimization Algorithms in Engineering, Business, Economics, and Finance, pp. 312–356. IGI Global. https://doi.org/10.4018/978-1-4666-2086-5.ch011

Taylor GD (2007) Inventory control theory: deterministic and stochastic models. In Logistics Engineering Handbook, pp. 229–254. CRC Press

Tee YS, Rossetti MD (2002) A robustness study of a multi-echelon inventory model via simulation. Int J Prod Econ 80(3):265–277. https://doi.org/10.1016/S0925-5273(02)00259-1

Tiwari S, Jaggi CK, Bhunia AK, Shaikh AA, Goh M (2017) Two-warehouse inventory model for non-instantaneous deteriorating items with stock-dependent demand and inflation using particle swarm optimization. Ann Oper Res 254(1):401–423. https://doi.org/10.1007/s10479-017-2492-5

Torres F, Urrea A (2006) Optimization of an inventory policy by tabu search. II Colombian Congress and I International Andean Conference. http://dspace.uniandes.edu.co:9090/xmlui/handle/1992/822

Tripathy PK, Pattnaik M (2009) Optimization in an inventory model with reliability consideration. Appl Math Sci 3(1):11–25

Tsai DM (2011) An optimal production and shipment policy for a single-vendor single-buyer integrated system with both learning effect and deteriorating items. Int J Prod Res 49(3):903–922. https://doi.org/10.1080/00207540903473375

Van Wijk ACC, Adan IJ, Van Houtum GJ (2019) Optimal lateral transshipment policies for a two location inventory problem with multiple demand classes. Eur J Oper Res 272(2):481–495. https://doi.org/10.1016/j.ejor.2018.06.033

Vaughan TS (2021) Application of a dynamic inventory policy to spare parts subject to age replacement. Int J Invent Res 6(1):79–102. https://doi.org/10.1504/Ijır.2021.113879

Veral EA, LaForge RL (1985) The performance of a simple incremental lot-sizing rule in a multilevel inventory environment. Decis Sci 16(1):57–72. https://doi.org/10.1111/j.1540-5915.1985.tb01475.x

Vidal GH, Villadiego DJ, Calle MM (2019) Inventory Planning and Control with Optimization and Simulation Considerations: A Case Study. Indian J Sci Technol 12:13. https://doi.org/10.17485/ijst/2019/v12i13/130121

Vidal GH, Villadiego DJ, Calle MM (2019) Inventory Management in Manufacturing Systems: A. Indian J Sci Technol 12:13. https://doi.org/10.17485/ijst/2019/v12i13/132758

Visentin A, Prestwich S, Rossi R, Tarim SA (2021) Computing optimal (R, s, S) policy parameters by a hybrid of branch-and-bound and stochastic dynamic programming. Eur J Oper Res 294(1):91–99. https://doi.org/10.1016/j.ejor.2021.01.012

Viswanath J, Dorapravina CT, Karthikeyan T, Raj AS (2019) Serving Israeli Queue on Single Product Inventory System with Lead Time for Replenishment Mathematical Analysis and Computing. ICMAC, Kalavakkam, p 161. https://doi.org/10.1007/978-981-33-4646-8_14

Book Google Scholar

Viswanathan S (1997) Note Periodic review (s.S) policies for joint replenishment inventory systems. Manag Sci 43(10):1447–1454. https://doi.org/10.1287/mnsc.43.10.1447

Voelkel MA, Sachs AL, Thonemann UW (2020) An aggregation-based approximate dynamic programming approach for the periodic review model with random yield. Eur J Oper Res 281(2):286–298. https://doi.org/10.1016/j.ejor.2019.08.035

Wan N, Li L, Wu X, & Fan J (2021). Risk minimization inventory model with a profit target and option contracts under spot price uncertainty. J Ind Manag Optim. https://doi.org/10.3934/jimo.2021093

Wang TY, Hu JM (2010) Heuristic method on solving an inventory model for products with optional components under stochastic payment and budget constraints. Expert Syst Appl 37(3):2588–2598. https://doi.org/10.1016/j.eswa.2009.08.017

Wang KJ, Lin YS, Jonas CP (2011) Optimizing inventory policy for products with time-sensitive deteriorating rates in a multi-echelon supply chain. Int J Prod Econ 130(1):66–76. https://doi.org/10.1016/j.ijpe.2010.11.009

Wang SP, Lee W, Chang CY (2012) Modeling the consignment inventory for a deteriorating item while the buyer has warehouse capacity constraint. Int J Prod Econ 138(2):284–292. https://doi.org/10.1016/j.ijpe.2012.03.029

Wee HM, Shum YS (1999) Model development for deteriorating inventory in material requirement planning systems. Comput Ind Eng 36(1):219–225. https://doi.org/10.1016/S0360-8352(99)00003-0

Wee HM, Widyadana GA (2012) Economic production quantity models for deteriorating items with rework and stochastic preventive maintenance time. Int J Prod Res 50(11):2940–2952. https://doi.org/10.1080/00207543.2011.578159

Widyadana GA, Wee HM (2012) An economic production quantity model for deteriorating items with multiple production setups and rework. Int J Prod Econ 138(1):62–67. https://doi.org/10.1016/j.ijpe.2012.02.025

Wikner J (1994) Dynamic modelling and analysis of information flows in production-inventory and supply chain systems. Linköping Linköping Institute of Technology

Wikner J (2005) Dynamic analysis of a production-inventory model. Kybernetes. https://doi.org/10.1108/03684920510595508

Wilcox W, Horvath PA, Griffis SE & Autry CW (2011) A Markov model of liquidity effects in reverse logistics processes: The effects of random volume and passage. Prod Econ 86-101. https://doi.org/10.1016/j.ijpe.2010.09.005

Wilson RH (1934) Scientific routine for stock control. Harv Bus Rev 13(1):116–128

Wu Y, Dong M (2008) Combining multi-class queueing networks and inventory models for performance analysis of multi-product manufacturing logistics chains. Int J Adv Manuf Technol 37(5):564–575. https://doi.org/10.1007/s00170-007-1004-1

Wu B, Sarker BR (2013) Optimal manufacturing and delivery schedules in a supply chain system of deteriorating items. Int J Prod Res 51(3):798–812. https://doi.org/10.1080/00207543.2012.674650

Yadav ASSS, Bansal KK, Shivani ASSSVR, Vanaja R (2020) FIFO in green supply chain inventory model of electrical components industry with distribution centers using particle swarm optimization. Adv Math Sci J 9(7):5115–5120. https://doi.org/10.37418/amsj.9.7

Yadav AS, Swami A, Kher G (2018) Particle swarm optimization of inventory model with two warehouses. Asian J Math Comp Res 17–26

Yalçiner AY (2021) Determination of the Cost-Effective Lot-Sizing Technique for Perishable Goods: a case study. Int J Manag Adm 5(9):33–46 ( https://dergipark.org.tr/en/pub/ijma/issue/60472/867955 )

Yang MF, Lin Y (2010) Applying the linear particle swarm optimization to a serial multi-echelon inventory model. Expert Syst Appl 37(3):2599–2608. https://doi.org/10.1016/j.eswa.2009.08.021

Yang HL, Teng JT, Chern MS (2001) Deterministic inventory lot-size models under inflation with shortages and deterioration for fluctuating demand. Naval Res Logist (NRL) 48(2):144–158. https://doi.org/10.1002/1520-6750(200103)48:2

Yang M (2008) Using data driven simulation to build inventory model. In 2008 Winter Simulation Conference, pp. 2595–2599. IEEE. https://doi.org/10.1109/WSC.2008.4736373

Yue D, Zhao G, Qin Y (2018) An M/M/1 queueing-inventory system with geometric batch demands and lost sales. J Syst Sci Complex 31(4):1024–1041. https://doi.org/10.1007/s11424-018-6277-y

Zanakis SH, Evans JR (1981) Heuristic “optimization”: Why, when, and how to use it. Interfaces 11(5):84–91. https://doi.org/10.1287/inte.11.5.84

Zandi P, Rahmani M, Azimi P (2021) Proposing a Model for Analyzing and Improving a Service System through Queue Theory and Simulation Approach Case: Hamedan Power Company. J Ind Manag Perspect 11(2 Summer 2021):67–100. https://doi.org/10.52547/jimp.11.2.67

Zhao QH, Chen S, Leung SC & Lai K (2010). Integration of inventory and transportation decisions in a logistics system. Transp Res 913-925. https://doi.org/10.1016/j.tre.2010.03.001

Zheng YS, Zipkin P (1990) A queueing model to analyze the value of centralized inventory information. Oper Res 38(2):296–307. https://doi.org/10.1287/opre.38.2.296

Download references

Acknowledgements

Thank you to the University of Sinú—Sectional Cartagena, Investigation Group Deartica—Colombia, for the support of their academic and scientific group.

Author information

Authors and affiliations.

Industrial Engineering Department, Universidad del Sinú–Seccional Cartagena, Grupo de Investigación Deartica, Bolívar, Colombia

Germán Herrera Vidal

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Germán Herrera Vidal .

Ethics declarations

Ethics approval.

The authors hereby state that the present work is in compliance with the ethical standards.

Consent to Participate

Not applicable.

Consent for Publication

The manuscript has not been published before and is not being considered for publication elsewhere.

Conflict of İnterest

The authors declare no competing interests.

Additional information

Publisher's note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Reprints and permissions

About this article

Vidal, G.H. Deterministic and Stochastic İnventory Models in Production Systems: a Review of the Literature. Process Integr Optim Sustain 7 , 29–50 (2023). https://doi.org/10.1007/s41660-022-00299-3

Download citation

Received : 10 September 2021

Revised : 25 October 2022

Accepted : 10 November 2022

Published : 09 December 2022

Issue Date : March 2023

DOI : https://doi.org/10.1007/s41660-022-00299-3

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Inventory models

- Production systems

- Deterministic

- Find a journal

- Publish with us

- Track your research

IMAGES

VIDEO

COMMENTS

This paper analyzes possible parameters of existing models of inventory control. An attempt is made to provide an up-to-date review of existing literature, concentrating on descriptions of the ...

a literature review on models of inventory management under uncertainty time it takes for an order to be fulfilled. A supplier usually has limited capacity; therefore,

A literature review on models of inventory management under uncertainty. Inventories are raw materials, work-in-process goods and completely finished goods that are considered to be the portion of business's assets that are ready or will be ready for sale. Formulating a suitable inventory model is one of the major concerns for an industry.

In such cases, fuzzy models of inventory management take an important place. This paper analyzes possible parameters of existing models of inventory control. An attempt is made to provide an up-to-date review of existing literature, concentrating on descriptions of the characteristics and types of inventory control models that have been developed.

Inventory management under demand uncertainty has been investigated by scholars from different angles in different real-world settings. ... The reorder model with continuous review optimizes the ordering policy of companies when there is a fixed cost and the decision-maker has the ... respectively. It has been well established in the literature ...

Contrary to established mathematical models of decision making under uncertainty, increased ambiguity results in increased mean absolute percentage error, and a corresponding decrease in profit. We also find a systematic bias toward underordering associated with increased ambiguity, which is over and above the bias associated with increased ...

Formulating a suitable inventory model is one of the major concerns for an industry. The earliest scientific inventory management researches date back to the second decade of the past century, but the interest in this scientific area is still great. Again considering the reliability of any process is an important…

Indeed, Mula et al. (2006b) have done an excellent review of demand uncertainty. The case of lead time uncertainty was less studied in the past, in spite of their significant importance. This paper examines specifically supply planning under uncertainties of lead times. Axsäter (2006) describe two different types of stochastic lead-times ...

Supply planning and inventory control under lead time uncertainty: a literature review and future directions. ... In practice, inventory management software like MRP is used by companies even if ignored the uncertainty of lead times. In this work, we investigate the influence of this type of uncertainty and existing solutions proposed in the ...

This paper reviews part of the work carried out, dealing with the optimization of the IM problem. The main objective of this study is to analyze different parameters of existing mathematical models of IMO, to deliver an overview describing the main factors of the problem. Keywords: Inventory Management Optimization Supply Chain.

Abstract. Inventory management under uncertainty is a widely investigated field and many different types of inventory models have been used to address inventory problems in practice. However, a look at the literature reveals that few papers are devoted to inventory planning and management in environments characterised by uncertainty resulting ...

Over the past two decades, there has been explosive growth in the application of robust optimization in operations management (robust OM), fueled by both significant advances in optimization theory and a volatile business environment that has led to rising concerns about model uncertainty. We review some common modeling frameworks in robust OM ...

Inventory management under uncertainty is a widely investigated field and many different types of inventory models have been used to address inventory problems in practice. However, a look at the literature reveals that few papers are devoted to inventory planning and management in environments characterised by uncertainty resulting from ...

They reviewed and classified the literature and then focused on the uncertainty of demand and the response to stockouts. ... A literature review on models of inventory management under uncertainty. BSE 5, 26 (2015). ... C.D.C., Kundakcioglu, O.E.: A literature review on inventory management in humanitarian supply chains. Surv. Oper. Res. Manage ...

Literature review. Inventory management under uncertainty originated in the 1950's and the first significant contribution to this field was provided in 1951 by Arrow, Harris, and Marschak (1951) in which they present a dynamic inventory model with random demand described by a known probability distribution.

This paper focuses on the use of inventory models to control the material flow and purchased inventory items in manufacturing companies. The objectives of this paper are to assess the effects of demand uncertainty on inventory management and to evaluate the difference on uncertain demand subject to demand controls as determined and the models used. Three inventory management models are studied ...

The aim of this article to present a renewed information about the developed inventory models under different situations. ... an attempt is made to provide an up-to-date and complete review of existing literature, concentrating on descriptions of the characteristics and types of inventory control models that have been developed by Indian as ...

Conclusion This research contributes to the existing literature on FMCG organisations by finding out if a relationship between Inventory management and uncertain demand exist. 72.2 % of the respondents indicated that demand uncertainty have effects on inventory management by agreeing to the statement, there is a strong positive effect between ...

Inventory modeling allows understanding and knowing the behavior of production systems, based on the construction, solution and analysis of a representation of the real world, which allows an adequate management of the operations of any type of company or chain network. the objective of this research is focused on a literature review of deterministic and stochastic inventory models in ...

The main inventory management models are applied in environments where the demand or supply is random or uncertain. Generically, the studies proposed in the literature takes advantage of this inventory management models considering the demand as a distribution function (e.g., normal, gamma, and other) or as time series forecasting.