Sugar Production Business Plan [Sample Template]

By: Author Tony Martins Ajaero

Home » Business Plans » Food Sector » Food Processing

Do you want to start a sugar production company? If YES, here is a detailed sample sugar production business plan template & FREE feasibility report.

If you are certain that you have a winning formula when it comes to producing sugar, then you should consider launching your own sugar production company. It is a business that is still open for investors. Below is a sample sugar production company business plan that will help you launch your own business.

A Sample Sugar Production Business Plan Template

1. industry overview.

Sugar is one commodity that is consumed in all parts of the world and those that are in the business of producing sugar are known to generate sales year in year out if the business is well managed. The Sugar Processing industry is made up of businesses that manufacture raw sugar, liquid sugar and refined sugar from sugarcane, raw cane sugar and sugar beets.

This industry acquires its raw material from sugarcane growers. Sugar refiners also buy raw sugar from millers. This raw material is processed into a range of sugar products for industrial and consumer use. A recent report released by IBISWorld shows that the united states Sugar Processing industry is in decline, exhibiting falling revenue and industry value added (IVA).

Over the five years through 2010, IBISWorld forecasts that revenue will decrease at an average annual rate of 2.5 percent. Several factors determine the industry’s decline, including volatile prices and production in upstream supply industries, changing consumer tastes and demand, and increasing international trade. However, the industry is highly assisted.

Industry participants enjoy several levels of protection, including non-recourse loans, marketing allotments and tariff rate quotas. In the five years through 2010, these government policies will act as internal price supports for the industry, allowing operators to earn high profit margins by passing on increasing input costs to their downstream markets.

In the last five years, the industry has experienced a slight decline in revenue primarily driven by decrease in input prices. The price of raw sugar most significantly affects industry revenue.

Industry operators typically benefit from higher input prices because they can pass the costs to consumers in the form of higher prices. Consumers typically purchase these goods regardless of price hikes since sugar products are a staple of the average American diet.

The Sugar Processing industry is a thriving sector of the economy of the United States of America and they generate over $10 billion annually from more than 97 registered and licensed sugar production companies scattered all around the United States of America.

The industry is responsible for the employment of over 13,879 people. Experts projected the Sugar Processing industry to grow at 0.6 percent annual rate within 2014 and 2019. Louis-Dreyfus Company B.V., American Crystal Sugar Company and Florida Crystals Corporation are the market leaders in the Sugar Processing industry.

Despite the fact that there are big corporations who are into the production of sugar, the fact remains that starting a small – scale sugar production business has minimal barriers to entry, with relative minimal startup capital.

Some of the factors that encourage aspiring entrepreneurs to start a sugar production company is the fact that the market for sugar cuts across people of all races, culture, financial status and age. That makes it easier for entrepreneur who are interested in the business to come into the industry at any time they desire.

The sugar processing industry is a profitable industry and it is open for any aspiring entrepreneur to come in and establish his or her business; you can choose to start on a small scale servicing a community or you can choose to start on a large scale with distribution network and several outlets in key cities all around the United States of America.

2. Executive Summary

St. Vicarage® Sugar Production Co, LLC is a licensed sugar production company that will be located around one of the largest sugarcane plantations in Rio Rancho – New Mexico. We have been able to secure a long – term lease for a facility in a strategic location with an option of a long – term renewal on terms and conditions that are favorable to us.

The facility has government approval for the kind of production business we want to run and the facility is easily accessible.

St. Vicarage® Sugar Production Co, LLC is in the Sugar Processing industry to manufacture raw sugar, liquid sugar and refined sugar from sugarcane and sugar beets. We are also in business to make profits at the same to give our customers value for their money.

We are aware that there are several sugar production companies around the United States, which is why we spent time and resources to conduct our feasibility studies and market survey.

We ensured that our facility is easy to locate and we have mapped out plans to develop a far – reaching distribution network for wholesalers of sugar products all around Rio Rancho – New Mexico and throughout the United States of America.

Beyond producing quality, sugars, our customer care is going to be second to none. We know that our customers are the reason why we are in business which is why we will go the extra mile to get them satisfied when they purchase our sugar.

St. Vicarage® Sugar Production Co, LLC is family business that will be owned by Moses Pablo and her immediate family members.

Mr. Moses Pablo who is the Chief Executive Officer of the Company is Graduate of Biochemistry and he holds a Master’s Degree in Business Management (MBA). He has over 15 years’ experience working in related industry as a senior manager prior to starting St. Vicarage® Sugar Production Co, LLC.

3. Our Products and Services

St. Vicarage® Sugar Production Co, LLC is going to run a standard sugar production company whose products will not only be sold in Rio Rancho – New Mexico but also throughout the United States of America and Canada. We are in the Sugar Processing industry to make profits and also to give our customers value for their money.

These are some of the products that we will be offering;

- Liquid sugar

- Crystal sugar

4. Our Mission and Vision Statement

- Our vision is to establish standard sugar production Company whose products will be not only be sold in Rio Rancho – New Mexico, but also throughout the United States of America and Canada.

- Our mission is to establish a standard and world class sugar production Company that in our own capacity will favorably compete with leaders in the industry.

- We want to build a business that will be listed amongst the top 20 sugar brands in the United States of America and Canada.

Our Business Structure

St. Vicarage® Sugar Production Co, LLC is established with the aim of competing favorably with other leading sugar brands in the industry. This is why we will ensure that we put the right structures in place that will support the kind of growth that we have in mind while setting up the business.

We will ensure that we only hire people that are qualified, honest, hardworking, customer centric and are ready to work to help us build a prosperous business that will benefit all the stake holders.

As a matter of fact, profit-sharing arrangement will be made available to all our senior management staff and it will be based on their performance for a period of ten years or more depending how fast we meet our set target. In view of that, we have decided to hire qualified and competent hands to occupy the following positions;

- Chief Executive Officer (Owner)

Plant Manager

Human Resources and Admin Manager

Merchandize Manager

Sales and Marketing Manager

- Machine Operators

- Accountants / Cashiers

Distribution Truck Drivers

5. Job Roles and Responsibilities

Chief Executive Officer – CEO (Owner):

- Increases management’s effectiveness by recruiting, selecting, orienting, training, coaching, counseling, and disciplining managers; communicating values, strategies, and objectives; assigning accountabilities; planning, monitoring, and appraising job results

- Creating, communicating, and implementing the organization’s vision, mission, and overall direction – i.e. leading the development and implementation of the overall organization’s strategy.

- Responsible for fixing prices and signing business deals

- Responsible for providing direction for the business

- Responsible for signing checks and documents on behalf of the company

- Evaluates the success of the organization.

- Responsible for overseeing the smooth running of the sugar production plant

- Part of the team that determines the quantity and quality of sugar products that are to be produced

- Map out strategies that will lead to efficiency amongst workers in the plant

- Responsible for training, evaluation and assessment of plant workers

- Ensures operation of equipment by completing preventive maintenance requirements; calling for repairs.

- Ensures that the plant meets the expected safety and health standard at all times.

- Responsible for overseeing the smooth running of HR and administrative tasks for the organization

- Defining job positions for recruitment and managing interviewing process

- Carrying out staff induction for new team members

- Responsible for training, evaluation and assessment of employees

- Oversee the smooth running of the daily office and factory activities.

- Manage vendor relations, market visits, and the ongoing education and development of the organizations’ buying teams

- Responsible for the purchase of raw sugarcane, raw cane sugar and sugar beets directly from sugarcane plantations and farms

- Responsible for planning sales, monitoring inventory, selecting the merchandise, and writing and pricing orders to vendors

- Manage external research and coordinate all the internal sources of information to retain the organizations’ best customers and attract new ones

- Model demographic information and analyze the volumes of transactional data generated by customer purchases

- Identify, prioritize, and reach out to new partners, and business opportunities et al

- Responsible for supervising implementation, advocate for the customer’s needs, and communicate with clients

- Document all customer contact and information

- Represent the company in strategic meetings

- Help increase sales and growth for the company

Accountant/Cashier

- Responsible for preparing financial reports, budgets, and financial statements for the organization

- Provides managements with financial analyses, development budgets, and accounting reports

- Responsible for financial forecasting and risks analysis.

- Performs cash management, general ledger accounting, and financial reporting

- Responsible for developing and managing financial systems and policies

- Responsible for administering payrolls

- Ensuring compliance with taxation legislation

- Handles all financial transactions for the organization

- Serves as internal auditor for the organization

Client Service Executive

- Welcomes guests and clients by greeting them in person or on the telephone; answering or directing inquiries.

- Ensures that all contacts with clients (e-mail, walk-In center, SMS or phone) provides the client with a personalized customer service experience of the highest level

- Through interaction with clients on the phone, uses every opportunity to build client’s interest in the company’s products and services

- Manages administrative duties assigned by the manager in an effective and timely manner

- Consistently stays abreast of any new information on the company’s products, promotional campaigns etc. to ensure accurate and helpful information is supplied to clients

- Receives parcels / documents for the company

- Distribute mails in the organization

- Handles any other duties as assigned by the line manager

Production Workers/Machine Operators:

- Operate machines such as pasteurizers, evaporating machine/steamer, sugar extractor, stirring tank, and packaging machines et al.

- Assist in packaging and loading sugar products into distribution trucks

- Assist in loading and unloading sugar products

- Maintain a logbook of their driving activities to ensure compliance with federal regulations governing the rest and work periods for operators.

- Keep a record of vehicle inspections and make sure the truck is equipped with safety equipment

- Assist the transport and logistics manager in planning their route according to a delivery schedule.

- Transport finished goods and raw materials over land to and from manufacturing plants or retail and distribution centers

- Inspect vehicles for mechanical items and safety issues and perform preventative maintenance

- Comply with truck driving rules and regulations (size, weight, route designations, parking, break periods etc.) as well as with company policies and procedures

- Report defects, accidents or violations

6. SWOT Analysis

We are quite aware that there are several sugar manufacturing companies in the United States of America which is why we are following the due process of establishing a business.

We know that if a proper SWOT analysis is conducted for our business, we will be able to position our business to maximize our strength, leverage on the opportunities that will be available to us, mitigate our risks and be equipped to confront our threats.

St. Vicarage® Sugar Production Co, LLC employed the services of an expert HR and Business Analyst with bias in startup business to help us conduct a thorough SWOT analysis and to help us create a Business model that will help us achieve our business goals and objectives. This is the summary of the SWOT analysis that was conducted for St. Vicarage® Sugar Production Co, LLC;

Part of what is going to count as positives for St. Vicarage® Sugar Production Co, LLC is the vast experience of our management team, we have people on board who understand how to grow a business from the scratch to becoming a national phenomenon.

So also, our closeness to sugarcane plantations and beet farms, large national distribution network and of course our excellent customer service culture will definitely count as a strong strength for the business.

A major weakness that may count against us is the fact that we are a new sugar production company and we don’t have our own sugarcane plantation and beet farm hence we will initially depend on suppliers of raw sugarcane, raw cane sugar and sugar beets from farmers.

- Opportunities:

The trade-weighted index (TWI) measures the strength of the US dollar relative to the currencies of US trading partners. As the dollar appreciates, downstream industries can purchase sugar produced abroad at a lower cost, hurting industry revenue.

However, the US government highly regulates the level of sugar imports, reducing the influence of the TWI. The TWI is expected to increase gradually in the coming year. However, expected depreciation of the US dollar moving forward presents a potential opportunity for the industry.

Sugar processors in the United States produce raw sugar and refined sugar to sell. A rise in the price of sugar enables operators to sell sugar at a higher price and thus increases industry revenue.

The US Department of Agriculture assists the industry through a series of policies aimed at keeping the price of sugar steady. The price of sugar is expected to increase in the coming year, yet its price volatility poses a potential threat to the industry.

7. MARKET ANALYSIS

- Market Trends

A recent trend shows that industry players have been able to use health concerns to their advantage. In the last five years, research findings have suggested that the use of high fructose corn syrup (HFCS) in place of sugar increases the risk of obesity and insulin resistance. Sugar companies have used the information to market their product to the health-conscious consumer.

However, the volume of imports is expected to continue growing over the five years through 2010 even though the United States government imposes heavy tariffs on sugar imports. Falling revenues over the last five years have pushed many industry participants to consolidate and vertically integrate in order to cut costs.

Operators are taking advantage of economies of scale and economies of scope, increasing their capacities and producing more for a lower per-unit cost in order to battle the declining industry. As a result, the number of establishments is expected fall in the five years to 2010.

Similarly, industry players have cut back on labor costs, with employment also falling. Lastly, the industry’s adoption of eco-friendly practices will likely persuade environmentally conscious consumers to buy its products, while increasing operators’ efficiency.

8. Our Target Market

When it comes to selling sugar, there is indeed a wide range of available customers. In essence, our target market can’t be restricted to just a group of people, but all those who reside in our target market locations.

In view of that, we have conducted our market research and we have ideas of what our target market would be expecting from us. We are in business to engage in wholesale distribution and to retail our sugar to the following groups of people;

- Bakeries, cakes makers and confectioneries manufacturer

- Soda drinks manufacturers

- Snacks manufacturers

- Ice Cream makers

- Pharmaceutical production companies

- Everybody in our target market location

Our Competitive Advantage

A quick of the Sugar Processing industry reveals that the market has become much more intensely competitive over the last decade. As a matter of fact, you have to be highly creative, customer centric and proactive if you must survive in this industry.

We are aware of the stiff competition and we are well prepared to compete favorably with other sugar production companies in Rio Rancho – New Mexico and throughout the United States and Canada. Part of what is going to count as competitive advantage for St. Vicarage® Sugar Production Co, LLC is the vast experience of our management team.

So also, closeness to some of the largest sugarcane plantations and beet farms, our large and far reaching national distribution network and of course our excellent customer service culture will definitely count as a strong strength for the business.

Lastly, our employees will be well taken care of, and their welfare package will be among the best within our category in the Sugar Processing industry, meaning that they will be more than willing to build the business with us and help deliver our set goals and achieve all our aims and objectives.

We will also give good working conditions and commissions to freelance sales agents that we will recruit from time to time.

9. SALES AND MARKETING STRATEGY

- Sources of Income

St. Vicarage® Sugar Production Co, LLC is established with the aim of maximizing profits in the sugar processing industry in both the United States of America and we are going to ensure that we do all it takes to sell our sugar to a wide range of customers.

We will generate income by selling;

10. Sales Forecast

One thing is certain when it comes to sugar production company, if your products are well – packaged and branded and if your production plant is centrally positioned and easily accessible, you will always attract customers cum sales and that will sure translate to increase in revenue for the business.

We are well positioned to take on the available market in Rio Rancho – New Mexico and every city where our sugar will be sold and we are quite optimistic that we will meet our set target of generating enough income/profits from the first six months of operation and grow the business and our clientele base.

We have been able to critically examine the sugar processing industry and we have analyzed our chances in the industry and we have been able to come up with the following sales forecast.

Below are the sales projections for St. Vicarage® Sugar Production Co, LLC, it is based on the location of our business and other factors as it relates to small scale and medium scale sugar production company startups in the United States;

- First Fiscal Year (FY1): $350,000

- Second Fiscal Year (FY2): $550,000

- Third Fiscal Year (FY3): $950,000

N.B : This projection was done based on what is obtainable in the industry and with the assumption that there won’t be any major economic meltdown and there won’t be any major competitor offering same products as we do within same location. Please note that the above projection might be lower and at the same time it might be higher.

- Marketing Strategy and Sales Strategy

Before choosing a location to start St. Vicarage® Sugar Production Co, LLC and also the kind of sugar products we produce, we conducted a thorough market survey and feasibility studies in order for us to penetrate the available market in our target market locations.

We have detailed information and data that we were able to utilize to structure our business to attract the number of customers we want to attract per time and also for our products to favorable compete with other leading sugar brands in the United States of America.

We hired experts who have good understanding of the sugar processing industry to help us develop marketing strategies that will help us achieve our business goal of winning a larger percentage of the available market in Rio Rancho – New Mexico.

In summary, St. Vicarage® Sugar Production Co, LLC will adopt the following sales and marketing approach to sell our sugar;

- Open our sugar production company with a party so as to capture the attention of residents who are our first targets

- Engage in roadshow in targeted communities from time to time to sell our products

- Advertise our products in community – based newspapers, local TV and radio stations

- List our business and products on yellow pages ads (local directories)

- Leverage on the internet to promote our sugar brands

- Engage in direct marketing and sales

- Encourage the use of Word of mouth marketing (referrals)

11. Publicity and Advertising Strategy

St. Vicarage® Sugar Production Co, LLC has a long – term plan of distributing our sugar in various locations all around the United States of America and Canada which is why we will deliberately build our brand to be well accepted first in Rio Rancho – New Mexico before venturing out.

Here are the platforms we intend leveraging on to promote and advertise St. Vicarage® Sugar Production Co, LLC;

- Place adverts on both print (community – based newspapers and magazines) and electronic media platforms

- Sponsor relevant community programs

- Leverage on the internet and social media platforms like; Instagram, Facebook, twitter, et al to promote our sugar brand

- Engage in roadshow from time to time in targeted communities

- Distribute our fliers and handbills in target areas

- Position our Flexi Banners at strategic positions in the location where we intend getting customers to start patronizing our products.

- Ensure that our products are well branded and that all our staff members wear our customized clothes, and all our official cars and distribution vans are customized and well branded.

12. Our Pricing Strategy

Our prices will conform to what is obtainable in the industry but will ensure that within the first 6 to 12 months our products are sold a little bit below the average prices of various sugar brands in the United States of America. We have put in place business strategies that will help us run on low profits for a period of 6 months; it is a way of encouraging people to buy into our sugar brand.

- Payment Options

The payment policy adopted by St. Vicarage® Sugar Production Co, LLC is all inclusive because we are quite aware that different customers prefer different payment options as it suits them but at the same time, we will ensure that we abide by the financial rules and regulation of the United States of America.

Here are the payment options that St. Vicarage® Sugar Production Co, LLC will make available to her clients;

- Payment via bank transfer

- Payment with cash

- Payment via credit cards

- Payment via online bank transfer

- Payment via check

- Payment via mobile money transfer

- Payment via bank draft

In view of the above, we have chosen banking platforms that will enable our client make payment for sugar purchase without any stress on their part. Our bank account numbers will be made available on our website and promotional materials.

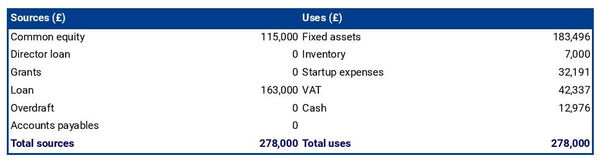

13. Startup Expenditure (Budget)

Starting a standard sugar production company is indeed a capital – intensive business because the amount required in setting up a sugar production plant is not a pocket money. The bulk of the startup capital will be spent on leasing or acquiring a facility and also in purchasing pasteurizers, evaporating machine / steamer, sugar extractor, stirring tank, crystalizing machines, a mini lab and good drainage system.

You are also expected to purchase distribution trucks, purchase raw materials, pay your employees and utility bills. These are the key areas where we will spend our startup capital;

- The Total Fee for Registering the Business in the United States of America – $750.

- Legal expenses for obtaining licenses and permits as well as the accounting services (software, P.O.S machines and other software) – $1,300.

- Marketing promotion expenses for the grand opening of St. Vicarage® Sugar Production Co, LLC in the amount of $3,500 and as well as flyer printing (2,000 flyers at $0.04 per copy) for the total amount of – $3,580.

- The cost for hiring Business Consultant – $2,500.

- The cost for insurance (general liability, workers’ compensation and property casualty) coverage at a total premium – $2,400.

- The cost for payment of rent for 12 months at $1.76 per square feet in the total amount of $105,600.

- The cost for construction of a standard sugar production plant – $100,000.

- Other start-up expenses including stationery ($500) and phone and utility deposits ($2,500).

- Operational cost for the first 3 months (salaries of employees, payments of bills et al) – $100,000

- The cost for Start-up inventory (refrigerated tank trucks, pasteurizers, evaporating machine / steamer, sugar extractor, stirring tank, crystalizing machines, a mini lab and good drainage system, supply of raw sugar, and packaging materials et al) – $80,000

- The cost for store equipment (cash register, security, ventilation, signage) – $13,750

- The cost of purchase of distribution vans – $60,000

- The cost for the purchase of furniture and gadgets (Computers, Printers, Telephone, Fax Machines, tables and chairs et al) – $4,000.

- The cost of launching a website – $600

- The cost for our opening party – $10,000

- Miscellaneous – $10,000

We would need an estimate of four hundred and fifty thousand dollars ($450,000) to successfully set up our sugar production plant in Rio Rancho – New Mexico. P

Generating Funds / Startup Capital for St. Vicarage® Sugar Production Co, LLC

St. Vicarage® Sugar Production Co, LLC is a family business that is owned and financed by Moses Pablo and his immediate family members. They do not intend to welcome any external business partner which is why he has decided to restrict the sourcing of the startup capital to 3 major sources.

- Generate part of the start – up capital from personal savings and sell of stocks

- Source for soft loans from family members and friends

- Apply for loan from my Bank

N.B: We have been able to generate about $200,000 (Personal savings $150,000 and soft loan from family members $50,000) and we are at the final stages of obtaining a loan facility of $250,000 from our bank. All the papers and documents have been signed and submitted, the loan has been approved and any moment from now our account will be credited with the amount.

14. Sustainability and Expansion Strategy

Part of the plans we have in place to sustain St. Vicarage® Sugar Production Co, LLC is to ensure that we continue to make available a wide range of sugar, deliver quality services, improvise on how to do things faster and cheaper. We are not going to relent in providing conducive environment for our workers and also the required trainings that will help them deliver excellent services at all times.

We are quite aware that our customers are key component to the growth and survival of our business hence we are going to continuously engage them to give us ideas on how to serve them better and the products they want to see in our store.

We will not waste time in adopting new technology, best practices and diversifying our services. St. Vicarage® Sugar Production Co, LLC will make sure that the right foundation, structures and processes are put in place to ensure that our staff welfare are well taken of.

Our company’s corporate culture is designed to drive our business to greater heights and training and retraining of our workforce is at the top burner. We know that if that is put in place, we will be able to successfully hire and retain the best hands we can get in the industry; they will be more committed to help us build the business of our dreams.

Check List/Milestone

- Business Name Availability Check: Completed

- Business Registration: Completed

- Opening of Corporate Bank Accounts: Completed

- Securing Point of Sales (POS) Machines: Completed

- Opening Mobile Money Accounts: Completed

- Opening Online Payment Platforms: Completed

- Application and Obtaining Tax Payer’s ID: In Progress

- Application for business license and permit: Completed

- Purchase of Insurance for the Business: Completed

- Leasing of facility and construction of standard sugar production plant: In Progress

- Conducting Feasibility Studies: Completed

- Generating capital from family members and friends: Completed

- Applications for Loan from the bank: In Progress

- writing of business plan: Completed

- Drafting of Employee’s Handbook: Completed

- Drafting of Contract Documents and other relevant Legal Documents: In Progress

- Design of the Company’s Logo: Completed

- Printing of Packaging and Promotional Materials: In Progress

- Recruitment of employees: In Progress

- Purchase of the needed furniture, racks, shelves, computers, electronic appliances, office appliances and CCTV: In progress

- Creating Official Website for the Company: In Progress

- Creating Awareness for the business both online and around the community : In Progress

- Health and Safety and Fire Safety Arrangement (License): Secured

- Opening party/launching party planning : In Progress

- Establishing business relationship with vendors – wholesalers, sugarcane plantations, beet farmers, suppliers and merchants of sugar: In Progress

Related Posts:

- Fruit Shake Business Plan [Sample Template]

- Fruit Juice Production Business Plan [Sample Template]

- Marijuana Edibles Business Plan [Sample Template]

- Strawberry Jam Business Plan [Sample Template]

- Cold Press Oil Business Plan [Sample Template]

- Best Products

How To Start a Sugar Mill Business – Complete Guide

- February 15, 2024

- by Next What Business Research Team

Do you want to start a sugar milling business? Find here a detailed sugar mill project report with investment, and project cost for your ready reference.

The Sugar Industry in India forms the second-largest rural-based agro-industry next only to textiles. Given the steep increase in crude oil prices, the sugar industry has experienced an upswing in the last few years through the realization of better sugar prices. A sugar mill is also eco-friendly and offers a renewable source of energy through the generation of power from its co-product bagasse and alcohol from molasses.

A sugar mill comes under the category of medium to large-scale industrial sector in India. The Indian sugar industry is critical. First of all, it services the domestic market, the largest in the world, and on the other hand, it supports 50 million farmers and their families. In addition, a sugar processing plant is a very lucrative and profitable venture opportunity for entrepreneurs. However, this is a cash-intensive business. It demands substantial capital investment and strategic planning.

Is Sugar Mill Business Profitable?

Sugar has become one of the essential food consumption items globally, especially in urban areas. The future demand for sugar is expected to increase substantially given the present demand for the domestic market.

Additionally, sugar is an essential ingredient in the numerous processed food industries. The product has also a great demand in the export market. Some of the major sugar importing countries are China, Indonesia, the European Union, the United Arab Emirates, the United States, Bangladesh, etc.

In starting this business, you must have a business plan or project report in your hand. It is advisable to start the business with expert help. In addition, try to gather as much information about the sugar industry in your area.

Broadly, you will need to figure out the specific requirements of space, electricity, water, manpower, etc. In addition, you will need to determine the business size as per your investment capacity and risk-taking ability.

Here are the 7 Steps to Start a Sugar Mill Business

1. market research and feasibility study.

Conduct thorough market research to assess the demand for sugar and its by-products in your target region. Evaluate the feasibility of setting up a sugar mill by analyzing factors such as raw material availability (sugarcane), infrastructure, competition, and regulatory environment.

2. Business Plan Development

Develop a comprehensive business plan outlining your objectives, target market, production capacity, financial projections, marketing strategies, and operational plan. Your business plan will serve as a roadmap for the entire project and will be essential for obtaining financing from investors or financial institutions.

3. Site Selection and Land Acquisition

Identify a suitable location for your sugar mill considering factors such as proximity to sugarcane farms, availability of water and utilities, transportation infrastructure, and environmental considerations. Acquire the necessary land and obtain the required permits and approvals from local authorities.

4. Obtaining Regulatory Approvals

Before commencing operations, ensure compliance with all regulatory requirements and obtain necessary licenses and permits from government agencies such as the Food Safety and Standards Authority of India ( FSSAI ), Pollution Control Board, Ministry of Agriculture, and Ministry of Food Processing Industries.

5. Registration and Licensing

You will need to register the business first. It is advisable to select the right form of the organization according to the investment and management pattern. And go for the registration with ROC in India. After that, you will need to obtain different types of licenses and permissions to run the factory from the Govt. agencies. Nowadays GST registration is a must within a few days of registering your business.

Sugarcane is covered under the Essential Commodities Act due to its perishable nature and the need for regulation on cane supply and pricing. Additionally, if you are looking for export, you need to apply for the certifications. And here also, you must get help from an expert.

6. Sugar Mill Plant Setup

As this is a cash-intensive business, you must make every decision carefully. First of all, you must establish the unit near the sugar-producing areas. So, you can easily procure sugar cane from the farmers or growers.

Additionally, the space requirement of the plant depends on plant capacity. You will need to secure the land according to your business plan . Check the electricity and water supply arrangements. Even a mini sugar mill demands an adequate source of water supply for its operations.

7. Buy Machinery

Sugar milling is an integrated process that includes the operation of several machines at a time. Therefore, you must procure the plant from a reliable machine supplier. Here we put a list of some major required machinery.

- Mills tandem

- Vacuum filters

- Heat exchangers

- Vacuum evaporators

- Vacuum pans

- Crystallizers

- Centrifuges

- Fermentation Tanks

- Column still

- Electricity generators

- Fork lifters

- Alcohol tanks

- Molasses tanks

8. Raw Materials, Products and Byproducts

The main raw materials required for the production of sugar are sugar cane, sulfur, lime, and polyethylene bags. You can procure the sugar cane from the local farmers. However, you will need to ensure the specific quantity of raw materials according to the plant capacity.

Apart from the sugar, you will get two other byproducts that have commercial value. These are molasses and filter cake or press mud. Generally, distilleries and cattle feed producers are the major consumers of molasses.

On the other hand, the press mud is rich in minerals, potash as also phosphate, sulfites & organic matter which means rich manure. Hence, this is most suitable for soils. Therefore, it is a very good quality organic manure for agricultural activity.

9. Cost of Starting a Sugar Mill Business

The project cost typically depends on the expected production output. Broadly, there are two major investment areas in this industry. These are fixed capital investment and working capital investment. Generally, the fixed cost includes land & building, procuring plant & machinery, registration, licensing, permissions, and other preliminary expenses. The working capital includes procuring raw materials, staffing, utilities, transportation, and distribution expenses.

The approximate cost of plant and machinery for a sugar mill for 2500 tonnes processing capacity will be around 40 Cr to 50 Cr in Indian rupees. In addition to this, you need to invest in land, buildings, housing, working capital, etc. The total investment t will be a minimum of 125 Cr for setting up a sugar mill in India.

However, you can also consider starting a mini-sugar mill according to your investment capacity. There are several financing assistance available in India. However, you must have the eligibility to take loans from the banks.

10. Sugar Mill Manufacturing Process

The manufacturing process is not very simple. Therefore, you must hire specific manpower for the smooth operation of the factory.

- Step 1. The first step is collecting and procuring the sugar cane after harvesting. Generally, each ton of sugarcane produces about 100 kg of sugar. That means you can transform 10% of the total weight of the sugarcane into crystal sugar. An average yield per hectare is 80 tons of sugarcane.

- Step 2. You will need to slice and shred the sugar cane to facilitate juice extraction in the crushing process. Generally, you can use three or more sets of three-roller mills to press the juice out of the cane.

- Step 3. The next step is the purification of juice. You will need to remove the largest possible number of impurities at the beginning. You can apply sulphur dioxide and lime for purification. Additionally, adjust the final PH to 8-8.5. Then evaporate the clear juice to a concentration of 55-65% sucrose. In addition, you can generate steam with the help of boilers.

- Step 4. The next step is crystallization. Evaporate the concentrated juice further until you get saturated sugar. As the syrup becomes saturated, sugar crystals are formed. The final step is centrifuging. Here you get the finished sugar. Now the product is ready for packaging and distribution.

11. Staffing For Sugar Mill

Manpower planning is an important factor in this business. Broadly, you will need to hire employees for three specific divisions. These are the production team, sales team, and accounting personnel. Additionally, you will need to specify the actual manpower requirement for each segment in the sugar mill operation.

12. Marketing and Distribution

Develop a marketing strategy to promote your sugar mill products and establish distribution channels to reach your target market. Explore opportunities for selling sugar and its by-products to wholesalers, retailers, industrial consumers, and export markets.

Frequently Asked Questions

Is it necessary to have prior experience in the sugar industry to start a sugar mill business.

While prior experience in the sugar industry can be beneficial, it is not always necessary to have the specific industry experience to start a sugar mill business. However, having a team with relevant expertise in areas such as agriculture, engineering, operations management, and finance can greatly enhance the chances of success.

How long does it take to set up and start operations of a sugar mill in India?

The timeline for setting up and starting operations of a sugar mill in India can vary depending on factors such as the availability of land, infrastructure development, regulatory approvals, procurement of machinery and equipment, and recruitment of personnel. On average, it may take anywhere from one to three years to establish a sugar mill from inception to full-scale production.

What are the key challenges faced by entrepreneurs in the sugar mill business?

Some common challenges faced by entrepreneurs in the sugar mill business include fluctuating sugarcane prices, labour management issues, regulatory compliance, competition from established players, managing operational costs, and market volatility. Implementing effective risk management strategies and staying updated on industry trends can help mitigate these challenges.

Are there government subsidies or incentives available for setting up a sugar mill business in India?

Yes, the Indian government offers various subsidies, incentives, and support schemes for entrepreneurs in the agro-industry sector, including sugar mill businesses. These subsidies may be available for areas such as capital investment, technology adoption, infrastructure development, and export promotion. Entrepreneurs are advised to research and avail themselves of relevant government schemes to support their sugar mill projects.

What are the potential market opportunities for sugar mill products in India?

India is one of the largest consumers of sugar globally, with a growing demand for both raw and refined sugar. Additionally, by-products of sugar production such as molasses, bagasse, and ethanol have diverse industrial applications, including in food and beverage manufacturing, pharmaceuticals, biofuels, and animal feed. Identifying niche market segments and value-added products can further enhance market opportunities for sugar mill businesses.

Is it possible to export sugar and its by-products from India?

Yes, Indian sugar mill businesses have the opportunity to export sugar and its by-products to international markets, subject to regulatory requirements and quality standards. Exporting sugar and its by-products can be a lucrative avenue for revenue diversification and accessing global markets with high demand for Indian agro-products.

The Editorial Staffs at NextWhatBusiness is a team of Business Consultants with years of experience in small and medium-scale manufacturing and service-based businesses.

- X (Twitter)

Related posts:

- How to Start a Profitable Bakery Business in India

- Best 20 Cooking Oil Manufacturing Business Ideas with High Profit

- Top 14 Profitable Biofertilizer Manufacturing Business Ideas

- How to Start Mint Cultivation Business (Pudina) – Information Guide

01 84 60 03 50

Sugar Production Business Plan : free template

Welcome to the comprehensive Sugar Production Business Plan presented by Sugar Production Ltd. In this meticulously crafted article, we outline the key aspects of our strategic vision to excel in the competitive sugar production industry. As a leading producer of premium sugar products, our business plan encompasses essential sections, including an executive summary, product and service offerings, market analysis, marketing and sales strategy, the management team, and detailed financial projections. Join us as we delve into the intricacies of our business strategy, emphasizing sustainability, quality, and innovation to propel Sugar Production Ltd towards a prosperous and impactful future

Need help with your business plan or forecast?

Call on an expert to help you realise your project.

Fast turnaround times , Attractive prices

Sugar Production Business Plan: Executive Summary

Introduction.

In this executive summary, we present an overview of the business plan for Sugar Production Ltd. This sugar production business plan outlines the company’s vision, mission, and core objectives. It provides a comprehensive outline of the business’s key components and strategic direction. The goal of this executive summary is to highlight the most crucial aspects of the business plan and attract potential investors and stakeholders.

Company Overview

Sugar Production Ltd is a leading company dedicated to the production and distribution of high-quality sugar products. We are committed to providing customers with premium sugar that meets the highest industry standards. Our state-of-the-art production facilities and sustainable practices set us apart from competitors, ensuring long-term success and profitability.

Market Analysis

The sugar production industry is a vital sector in the global economy, with a steady demand for sugar in various industries, including food and beverage, pharmaceuticals, and confectionery. Our extensive market research indicates a growing demand for natural and organic sugar products, presenting an excellent opportunity for Sugar Production Ltd to capitalize on this trend.

Competitive Advantage

Sugar Production Ltd’s competitive advantage lies in its commitment to sustainable and eco-friendly practices. Our production processes prioritize environmental responsibility, ensuring that our products appeal to environmentally conscious consumers. Additionally, our strategic location allows us to access a steady supply of raw materials and distribute our products efficiently.

Financial Projections

Based on detailed financial analysis and market forecasts, Sugar Production Ltd expects substantial growth and profitability over the next five years. With projected revenue increases and cost optimization measures, we are confident in our ability to achieve significant returns for our stakeholders.

In conclusion, the Sugar Production Ltd business plan outlines a promising venture in the sugar production industry. Our commitment to excellence, sustainability, and customer satisfaction positions us as a leading player in the market. By investing in Sugar Production Ltd, stakeholders will be joining a dynamic and innovative company with significant growth potential

Other business plans in the same category

Swimwear & Beachwear

Sugar production business plan: product and service, product description.

Sugar Production Ltd specializes in the manufacturing of high-quality sugar products, catering to a diverse range of industries. Our product portfolio includes: 1. Granulated Sugar: Our premium granulated sugar is ideal for household use and various food applications. It is available in various packaging options to meet the needs of consumers and businesses. 2. Brown Sugar: We produce top-grade brown sugar with a rich flavor profile, perfect for baking and cooking purposes. Its distinctive taste makes it a popular choice among chefs and home bakers alike. 3. Organic Sugar: As a company committed to sustainability, we offer organic sugar produced from organic sugarcane without the use of synthetic chemicals. It appeals to health-conscious consumers looking for natural alternatives. 4. Specialty Sugars: We also produce specialty sugars, such as powdered sugar, superfine sugar, and demerara sugar, which cater to specific culinary needs.

Quality Assurance

At Sugar Production Ltd, quality is our top priority. We adhere to stringent quality control measures throughout the production process to ensure that our sugar products meet the highest standards. From sourcing raw materials to packaging the final product, every step is closely monitored to maintain consistency and excellence.

Production Process

Our state-of-the-art production facility employs cutting-edge technology and follows industry best practices. The production process begins with carefully selecting high-quality sugarcane, which is then crushed to extract the juice. The extracted juice undergoes purification and clarification to remove impurities. Next, the juice is concentrated and crystallized to form raw sugar. Through further refining and processing, we obtain the final product in various forms, such as granulated, brown, and specialty sugars.

Service Offerings

Apart from supplying premium sugar products, Sugar Production Ltd offers excellent customer service and support. Our dedicated sales team is always available to assist customers with product inquiries, orders, and delivery arrangements. We pride ourselves on building strong relationships with our clients, ensuring their satisfaction and loyalty.

Customization

Understanding that different customers have unique requirements, Sugar Production Ltd offers product customization services. Whether it’s personalized packaging, private labeling, or specific sugar specifications, we work closely with clients to fulfill their needs effectively.

Environmental Responsibility

Sugar Production Ltd is committed to sustainable and environmentally friendly practices. We implement water and energy conservation measures in our production processes, and we actively participate in community initiatives to promote environmental awareness

Sugar Production Business Plan: Market Analysis

Industry overview.

The sugar production industry plays a critical role in the global economy, providing a key ingredient for numerous consumer goods and industrial products. Sugar is a staple in the food and beverage sector, confectionery industry, pharmaceuticals, and even renewable energy production. The industry’s steady demand and diverse applications make it a lucrative and sustainable venture.

Market Trends

1. Increasing Health Consciousness: As consumers become more health-conscious, there is a growing demand for natural and organic sugar products. Health-conscious individuals are seeking alternatives to refined sugars and are willing to pay a premium for healthier options. 2. Sustainability and Eco-Friendly Practices: Environmental concerns are influencing consumer choices. Sugar Production Ltd’s commitment to sustainability and eco-friendly practices positions the company well to tap into this growing market segment. 3. Rise in Artisanal and Gourmet Food Industry: The trend of artisanal and gourmet food products is gaining traction. Premium sugar products, such as specialty sugars and organic varieties, are in demand among chefs, bakers, and food enthusiasts. 4. Global Market Expansion: The global sugar market continues to expand, driven by population growth, urbanization, and changing dietary patterns. Emerging markets present significant opportunities for sugar producers to expand their customer base.

Target Market

Sugar Production Ltd targets a diverse range of customers: 1. Food and Beverage Manufacturers: We supply bulk quantities of sugar to food and beverage manufacturers for the production of various goods, including baked goods, beverages, and processed foods. 2. Retail Consumers: Our packaged granulated sugar and specialty sugar products are available in retail stores, catering to individual consumers for home use. 3. Hospitality Sector: The hospitality industry, including hotels, restaurants, and cafes, relies on our quality sugar products for their food and beverage service. 4. Bakeries and Confectioneries: Bakers and confectioners appreciate the premium quality of our sugar, which is essential for achieving superior taste and texture in their creations.

Competitor Analysis

The sugar production industry is competitive, with several established players and new entrants vying for market share. Our main competitors include large multinational sugar producers and regional manufacturers. However, Sugar Production Ltd’s focus on sustainability, premium quality, and customer-centric approach sets us apart from many competitors.

SWOT Analysis

Strengths: • High-quality and diverse sugar product portfolio. • Strong commitment to sustainability and eco-friendly practices. • Efficient and modern production facility. • Excellent customer service and customization options. Weaknesses: • Relatively smaller market share compared to some major competitors. • Limited brand recognition in certain regions. Opportunities: • Growing demand for organic and specialty sugar products. • Expanding into emerging markets with increasing sugar consumption. • Partnerships with food manufacturers for exclusive supply arrangements. Threats: • Fluctuating sugarcane prices and raw material availability. • Intense competition in the sugar production sector. • Changes in government policies and regulations affecting the industry.

The market analysis indicates promising prospects for Sugar Production Ltd. By capitalizing on market trends, targeting diverse customer segments, and leveraging our competitive advantages, we are well-positioned to thrive in the sugar production industry

Sugar Production Business Plan: Marketing & Sales Strategy

Brand positioning.

Sugar Production Ltd aims to establish itself as a leading provider of premium sugar products with a focus on sustainability and exceptional quality. Our brand positioning centers on promoting natural, organic, and specialty sugar offerings to health-conscious consumers and culinary professionals. Through effective branding and marketing, we aim to differentiate ourselves from conventional sugar producers and attract a loyal customer base.

Targeted Marketing Channels

1. Digital Marketing: We will leverage digital platforms, including social media, search engine optimization (SEO), and online advertising, to reach a broader audience. Engaging content and visually appealing posts will showcase our products and sustainability initiatives. 2. Trade Shows and Exhibitions: Participating in relevant industry trade shows and exhibitions will allow us to showcase our products, network with potential buyers, and stay updated on industry trends. 3. B2B Partnerships: Collaborating with food and beverage manufacturers, bakeries, and confectioneries will open avenues for bulk sales and establish long-term partnerships. 4. Retail Promotions: In-store promotions, discounts, and product demonstrations will create brand awareness and encourage retail consumers to choose our products over competitors.

Online Sales Platform

To facilitate easy access for customers, we will launch an e-commerce website where individuals and businesses can directly purchase our sugar products. The website will offer a seamless shopping experience, secure payment options, and timely deliveries to various locations.

Customer Loyalty Program

To foster customer loyalty, we will implement a rewards program for regular customers, offering discounts, exclusive offers, and early access to new product launches. Building strong relationships with our customers will be a priority, as repeat business is essential for sustained growth.

Sales Team Training

Our sales team will undergo comprehensive training to equip them with in-depth knowledge of our product range, sustainability initiatives, and customer-centric approach. They will be trained to identify and address customer needs effectively, ensuring a positive buying experience.

Public Relations and Media Outreach

Engaging in public relations activities, such as press releases and media outreach, will help us showcase our commitment to sustainability and responsible business practices. Positive media coverage will bolster our brand image and build trust among consumers and stakeholders.

Marketing Budget Allocation

We will allocate a portion of our budget to marketing and promotional activities, with a focus on digital marketing and targeted campaigns. Regular analysis of marketing efforts’ effectiveness will guide future budget allocation and ensure optimal returns on investment.

Sugar Production Ltd’s marketing and sales strategy aims to position the company as a preferred choice for premium sugar products. By leveraging various marketing channels, emphasizing sustainability, and offering exceptional customer service, we are confident in our ability to achieve significant market penetration and revenue growth

Sugar Production Business Plan: The Management Team

Management structure.

The success of Sugar Production Ltd relies on the expertise and dedication of its management team. Our management structure is designed to ensure efficient decision-making, smooth operations, and a focus on achieving the company’s strategic goals.

Executive Team

1. [Founder/CEO Name]: As the visionary founder and CEO of Sugar Production Ltd, [Founder/CEO Name] brings extensive experience in the sugar industry. Their leadership and strategic direction have been instrumental in the company’s growth. 2. [COO Name]: The Chief Operating Officer oversees day-to-day operations, production processes, and supply chain management. [COO Name]’s operational expertise ensures seamless and efficient production and distribution. 3. [CFO Name]: As the Chief Financial Officer, [CFO Name] is responsible for financial planning, budgeting, and risk management. Their financial acumen ensures sound financial decisions and fiscal responsibility.

Production and Quality Control

1. [Production Manager Name]: The Production Manager oversees all aspects of sugar production, ensuring adherence to quality standards and production efficiency. 2. [Quality Control Manager Name]: The Quality Control Manager is responsible for maintaining the highest product quality and implementing quality assurance protocols.

Sales and Marketing Team

1. [Sales Manager Name]: The Sales Manager leads the sales team, developing sales strategies, and fostering strong customer relationships. 2. [Marketing Manager Name]: The Marketing Manager oversees all marketing initiatives, brand promotion, and customer engagement efforts.

Human Resources and Administration

1. [HR Manager Name]: The HR Manager handles recruitment, employee training, and talent development, ensuring a skilled and motivated workforce. 2. [Administration Manager Name]: The Administration Manager oversees day-to-day administrative tasks, facility management, and logistical operations.

Board of Advisors

Sugar Production Ltd is also guided by a team of experienced advisors who offer valuable insights and industry expertise. The board of advisors provides strategic direction, evaluates business performance, and ensures governance compliance.

Company Culture

At Sugar Production Ltd, we foster a culture of collaboration, innovation, and ethical practices. Our management team leads by example, promoting a positive and inclusive work environment where employees are encouraged to grow both professionally and personally. We value transparency and open communication, ensuring that every team member’s contributions are recognized and appreciated.

The dedicated and experienced management team at Sugar Production Ltd is committed to achieving the company’s vision and objectives. Their strategic leadership, combined with a skilled workforce, positions the company for continued success and growth in the competitive sugar production industry.

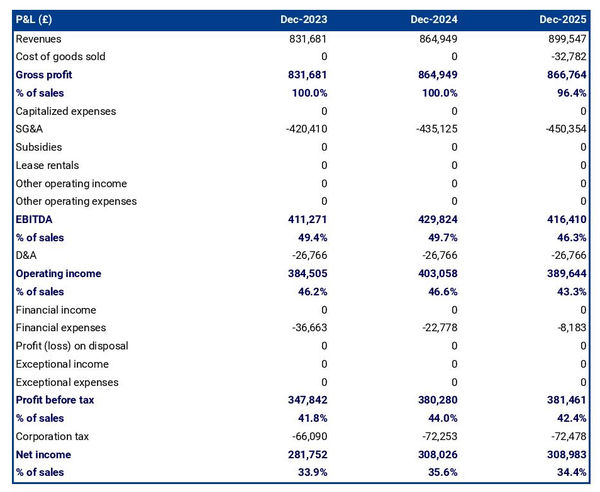

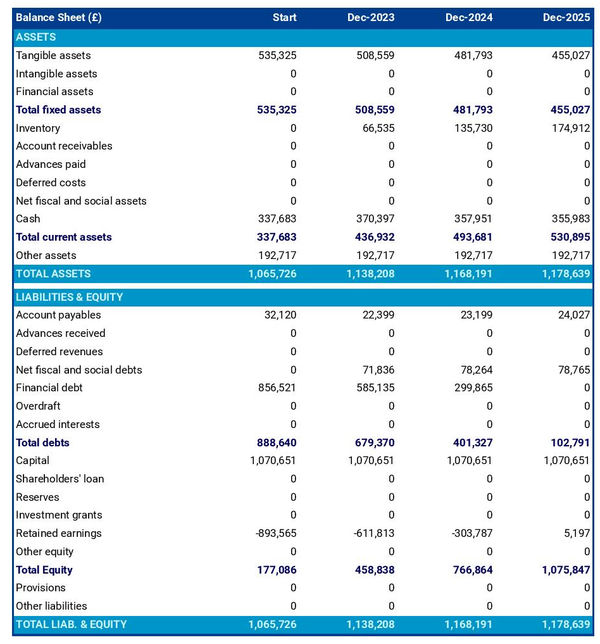

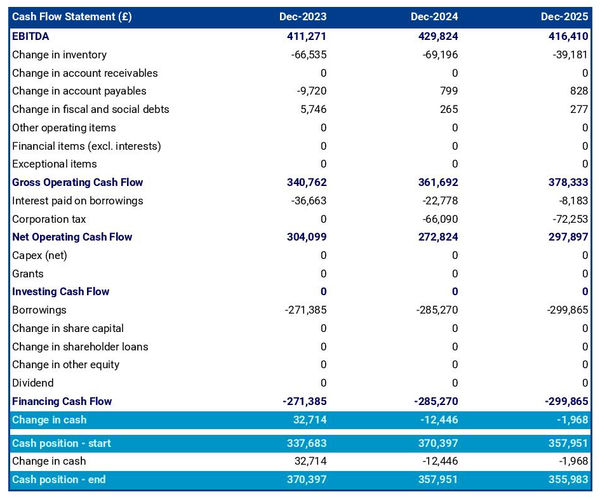

Sugar Production Business Plan: Financial Forecasts or Projections

Financial overview.

The financial forecasts for Sugar Production Ltd are based on extensive market research, historical data, and industry trends. The following financial projections outline the company’s expected performance over the next five years.

Revenue Projections

Year 1: • Total Revenue: $X million • Revenue Breakdown: • Granulated Sugar: $X million • Brown Sugar: $X million • Organic Sugar: $X million • Specialty Sugars: $X million Year 2: • Total Revenue: $X million • Revenue Breakdown: • Granulated Sugar: $X million • Brown Sugar: $X million • Organic Sugar: $X million • Specialty Sugars: $X million Year 3: • Total Revenue: $X million • Revenue Breakdown: • Granulated Sugar: $X million • Brown Sugar: $X million • Organic Sugar: $X million • Specialty Sugars: $X million Year 4: • Total Revenue: $X million • Revenue Breakdown: • Granulated Sugar: $X million • Brown Sugar: $X million • Organic Sugar: $X million • Specialty Sugars: $X million Year 5: • Total Revenue: $X million • Revenue Breakdown: • Granulated Sugar: $X million • Brown Sugar: $X million • Organic Sugar: $X million • Specialty Sugars: $X million

Expenses and Cost of Goods Sold (COGS)

The cost of goods sold (COGS) and operating expenses for each year are projected as follows: Year 1: • COGS: $X million • Operating Expenses: $X million Year 2: • COGS: $X million • Operating Expenses: $X million Year 3: • COGS: $X million • Operating Expenses: $X million Year 4: • COGS: $X million • Operating Expenses: $X million Year 5: • COGS: $X million • Operating Expenses: $X million

Profit Margin and Net Income

Based on the projected revenue and expenses, the net income and profit margin for each year are as follows: Year 1: • Net Income: $X million • Profit Margin: X% Year 2: • Net Income: $X million • Profit Margin: X% Year 3: • Net Income: $X million • Profit Margin: X% Year 4: • Net Income: $X million • Profit Margin: X% Year 5: • Net Income: $X million • Profit Margin: X%

Capital Expenditure

Over the next five years, Sugar Production Ltd plans to invest in modernizing and expanding its production facilities. The capital expenditure for each year is estimated as follows: Year 1: $X million Year 2: $X million Year 3: $X million Year 4: $X million Year 5: $X million

Cash Flow Projections

The cash flow projections take into account both operating and investing activities, ensuring the company’s liquidity and financial stability. The cash flow for each year is projected as follows: Year 1: $X million Year 2: $X million Year 3: $X million Year 4: $X million Year 5: $X million

The financial forecasts for Sugar Production Ltd demonstrate a promising outlook, with steady revenue growth and profitability over the next five years. By effectively managing expenses, investing in modernization, and capitalizing on market opportunities, the company is poised for success in the sugar production industry.

Articles similaires

Share this post, subscribe to our newsletter, autres articles qui pourraient vous intéresser.

Dry Cleaning Business Plan : free template

In the bustling world we live in, where time is of the essence and quality is paramount, (Dry Cleaning Ltd) emerges as

Bounce House Business Plan : free template

Welcome to an in-depth exploration of the exciting world of (Bounce House Ltd), where imagination knows no bounds and joyful memories are

Dairy Farm Business Plan : free template

In the ever-evolving landscape of the dairy industry, innovation, sustainability, and a strong strategic foundation are paramount for success. Welcome to a

Concrete Polishing Business Plan : free template

In a world where aesthetics, sustainability, and durability are paramount, the concrete polishing industry has emerged as a game-changer. Welcome to an

Convenience Store Business Plan : free template

In an ever-evolving world where time is of the essence and convenience is paramount, the role of a well-executed business plan cannot

Auto Parts Store Business Plan : free template

In a world where vehicles are an integral part of daily life, the demand for reliable auto parts and accessories continues to

Leave a Reply Cancel reply

© Societefacile.com 2023. All rights reserved.

You need a business plan or forecast!

Call on a specialist to help you with this tedious task

Reasonable rates

- Food & Beverages

Sugar Manufacturing Plant Project Report

Sugar manufacturing plant project report 2024: industry trends, plant setup, machinery, raw materials, investment opportunities, cost and revenue.

- Report Description

- Table of Contents

- Methodology

- Request Sample

Report Overview:

IMARC Group’s report titled “Sugar Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a sugar manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report also provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Sugar is a type of carbohydrate that is commonly found in numerous foods and drinks. It is a simple molecule made up of carbon, hydrogen, and oxygen, and it provides the body with energy. There are two main types of sugar, natural and added. Natural sugars are found in foods, such as fruits, vegetables, and dairy products, and they are generally considered to be healthy as they also contain essential nutrients. Added sugars, on the other hand, are added to foods and drinks during processing or preparation, and they provide calories but few other nutrients. However, consuming too much added sugar has been linked to a range of health problems, including obesity, type 2 diabetes, and heart disease. While consumption of added sugar does provide energy but to maintain a healthy lifestyle, it should always be done in moderation to avoid any adverse effect on health.

The widespread application of sugar in various industries, such as food and beverage and pharmaceuticals, represents one of the key factors driving the market growth. In line with this, food processing industry also extensively utilizes sugar in the preparation of various products, thus driving the market growth. Moreover, the rising demand for sugar-based products is acting as a major growth-inducing factor. This, coupled with significant expansion in the food processing industry is contributing to the market growth. The market is also being driven by the usage of sugar in the preparation of cough syrups and antibiotics in the pharmaceutical industry. In addition to this, as compared to its substitutes, sugar is more economical and easily available, is consumed across all socioeconomic age groups, and is easily obtainable, which, in turn, is acting as a major growth-inducing factor. Other factors, such as the easy product availability across various retails channels and the convenient access to raw materials, including sugar beet and sugarcane, for the production of sugar, are creating positive outlook for the market further across the globe.

The report provides a techno-commercial roadmap for setting up a sugar manufacturing plant. The study covers all the requisite aspects that one needs to know while entering the sugar industry. This report is a must-read for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the sugar industry.

The following aspects have been covered in the report on setting up a sugar manufacturing plant:

- Market Performance

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Outlook

The report provides insights into the landscape of the sugar industry at the global level. The report also provides a segment-wise and region-wise breakup of the global sugar industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of sugar, along with the industry profit margins.

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

The report also provides detailed information related to the process flow and various unit operations involved in a sugar manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, and expenditure for setting up a sugar manufacturing plant. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

.webp)

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

The report also covers a detailed analysis of the project economics for setting up a sugar manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a sugar manufacturing plant.

Profitability Analysis:

Report Coverage:

Key questions answered in this report.

- How has the sugar market performed so far and how will it perform in the coming years?

- What is the market segmentation of the global sugar market?

- What is the regional breakup of the global sugar market?

- What are the price trends of various feedstocks in the sugar industry?

- What is the structure of the sugar industry and who are the key players?

- What are the various unit operations involved in a sugar manufacturing plant?

- What is the total size of land required for setting up a sugar manufacturing plant?

- What is the layout of a sugar manufacturing plant?

- What are the machinery requirements for setting up a sugar manufacturing plant?

- What are the raw material requirements for setting up a sugar manufacturing plant?

- What are the packaging requirements for setting up a sugar manufacturing plant?

- What are the transportation requirements for setting up a sugar manufacturing plant?

- What are the utility requirements for setting up a sugar manufacturing plant?

- What are the human resource requirements for setting up a sugar manufacturing plant?

- What are the infrastructure costs for setting up a sugar manufacturing plant?

- What are the capital costs for setting up a sugar manufacturing plant?

- What are the operating costs for setting up a sugar manufacturing plant?

- What should be the pricing mechanism of the final product?

- What will be the income and expenditures for a sugar manufacturing plant?

- What is the time required to break even?

- What are the profit projections for setting up a sugar manufacturing plant?

- What are the key success and risk factors in the sugar industry?

- What are the key regulatory procedures and requirements for setting up a sugar manufacturing plant?

- What are the key certifications required for setting up a sugar manufacturing plant?

Report Customization

While we have aimed to create an all-encompassing report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

- The report can be customized based on the location (country/region) of your plant.

- The plant’s capacity can be customized based on your requirements.

- Plant machinery and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why Buy IMARC Reports?

- The insights provided in our reports enable stakeholders to make informed business decisions by assessing the feasibility of a business venture.

- Our extensive network of consultants, raw material suppliers, machinery suppliers and subject matter experts spans over 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- Our cost modeling team can assist you in understanding the most complex materials. With domain experts across numerous categories, we can assist you in determining how sensitive each component of the cost model is and how it can affect the final cost and prices.

- We keep a constant track of land costs, construction costs, utility costs, and labor costs across 100+ countries and update them regularly.

- Our client base consists of over 3000 organizations, including prominent corporations, governments, and institutions, who rely on us as their trusted business partners. Our clientele varies from small and start-up businesses to Fortune 500 companies.

- Our strong in-house team of engineers, statisticians, modeling experts, chartered accountants, architects, etc. have played a crucial role in constructing, expanding, and optimizing sustainable manufacturing plants worldwide.

India Dairy Market Report Snapshots Source:

Statistics for the 2022 India Dairy market share, size and revenue growth rate, created by Mordor Intelligence™ Industry Reports.

- India Dairy Market Size Source

- --> India Dairy Market Share Source

- India Dairy Market Trends Source

- India Dairy Companies Source

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Purchase options

Benefits of Customization

Personalize this research

Triangulate with your data

Get data as per your format and definition

Gain a deeper dive into a specific application, geography, customer, or competitor

Any level of personalization

Get in Touch With Us

UNITED STATES

Phone: +1-631-791-1145

Phone: +91-120-433-0800

UNITED KINGDOM

Phone: +44-753-713-2163

Email: [email protected]

Client Testimonials

IMARC made the whole process easy. Everyone I spoke with via email was polite, easy to deal with, kept their promises regarding delivery timelines and were solutions focused. From my first contact, I was grateful for the professionalism shown by the whole IMARC team. I recommend IMARC to all that need timely, affordable information and advice. My experience with IMARC was excellent and I can not fault it.

The IMARC team was very reactive and flexible with regard to our requests. A very good overall experience. We are happy with the work that IMARC has provided, very complete and detailed. It has contributed to our business needs and provided the market visibility that we required

We were very happy with the collaboration between IMARC and Colruyt. Not only were your prices competitive, IMARC was also pretty fast in understanding the scope and our needs for this project. Even though it was not an easy task, performing a market research during the COVID-19 pandemic, you were able to get us the necessary information we needed. The IMARC team was very easy to work with and they showed us that it would go the extra mile if we needed anything extra

Last project executed by your team was as per our expectations. We also would like to associate for more assignments this year. Kudos to your team.

.webp)